1. COMPLIANCE OF SAFE REPAIR ................................ 1

1-1.Cautions during Product Movement ........................ 1

1-2. Cautions during disassembling and assembling .... 1

2. SPECIFICATIONS ......................................................... 2

2-1. Product Specifications............................................ 2

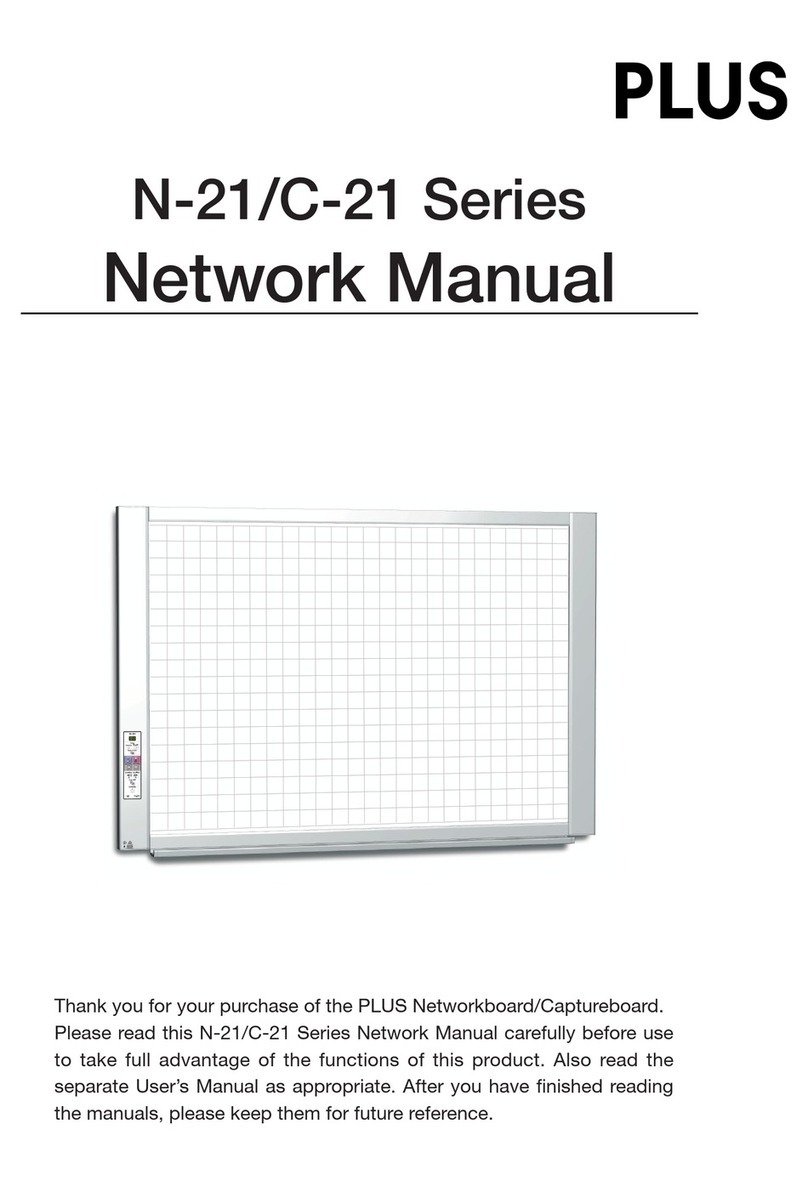

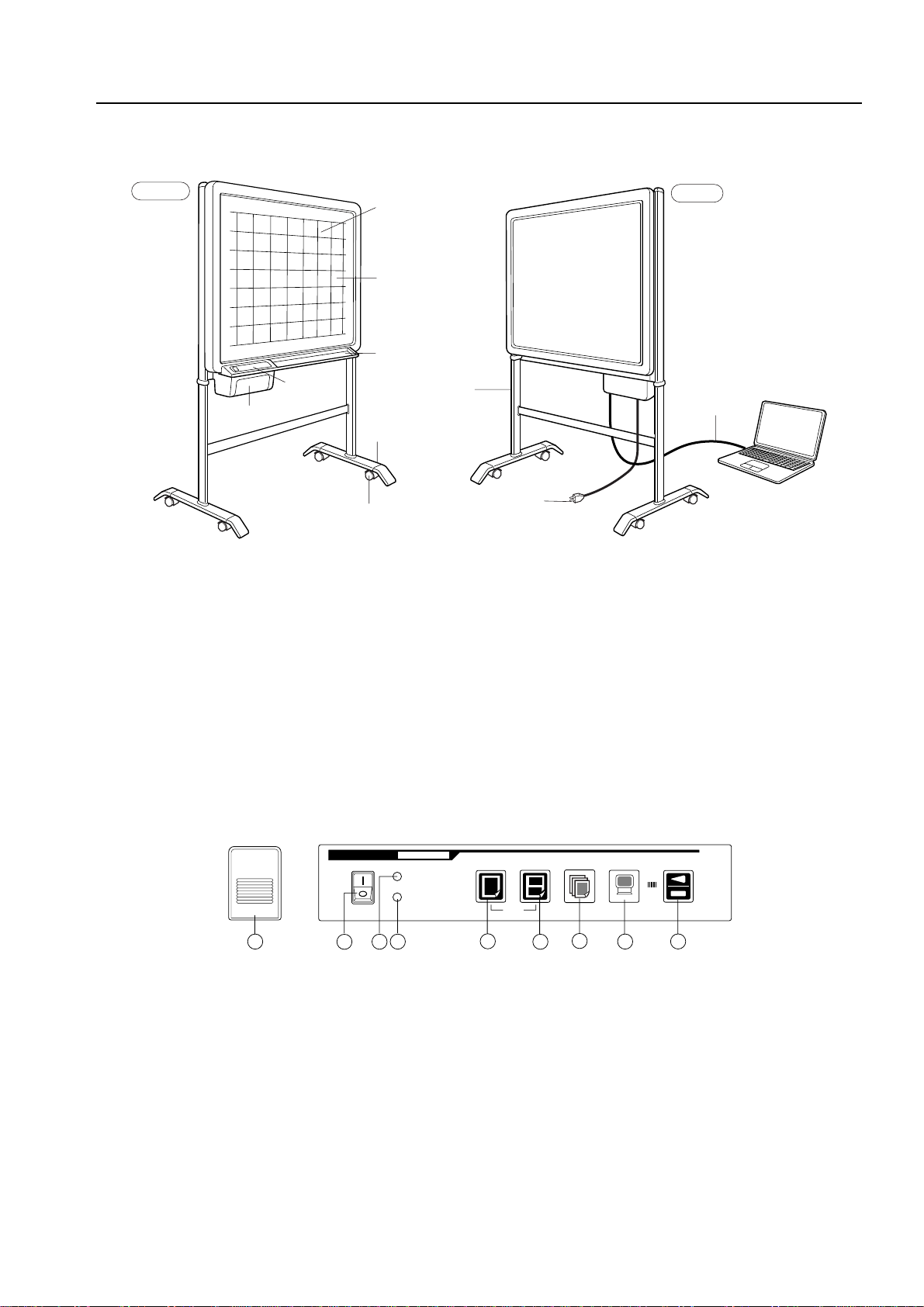

2-2. Location of Main Set............................................... 3

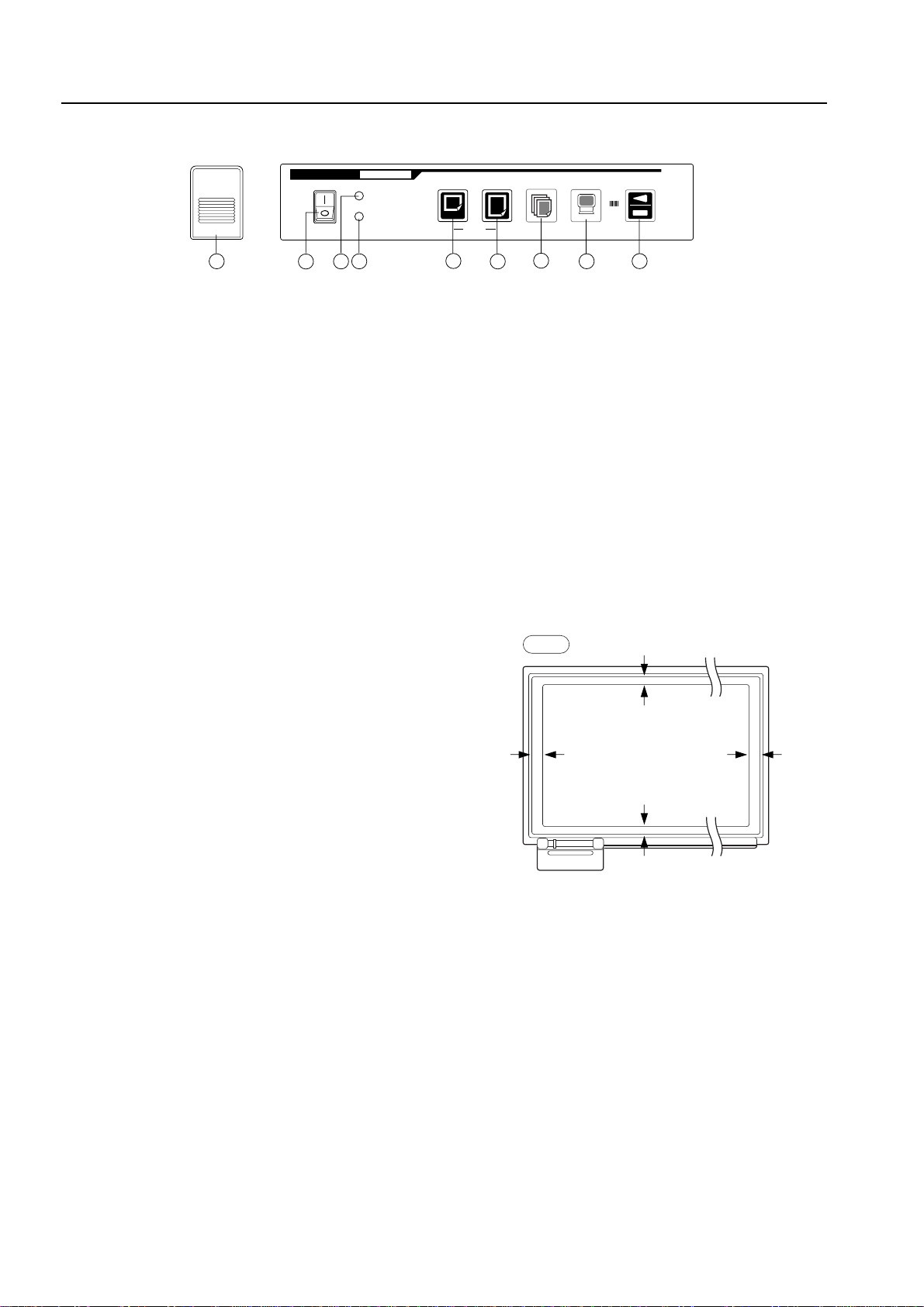

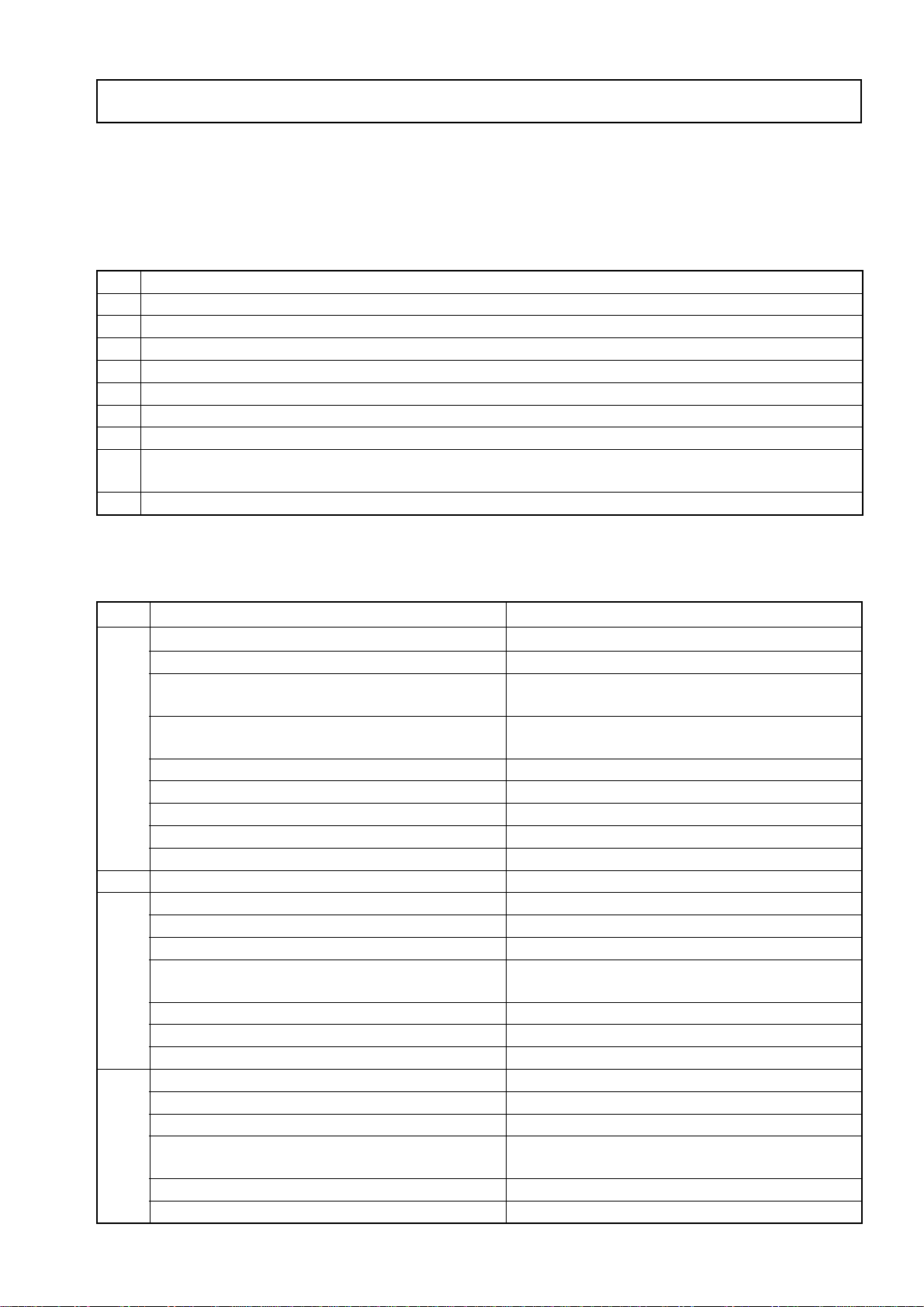

2-3. Operation Panel ..................................................... 4

2-4. Scanning Area ........................................................ 4

3. TROUBLE SHOOTING.................................................. 5

3-1. Trouble Shooting .................................................... 5

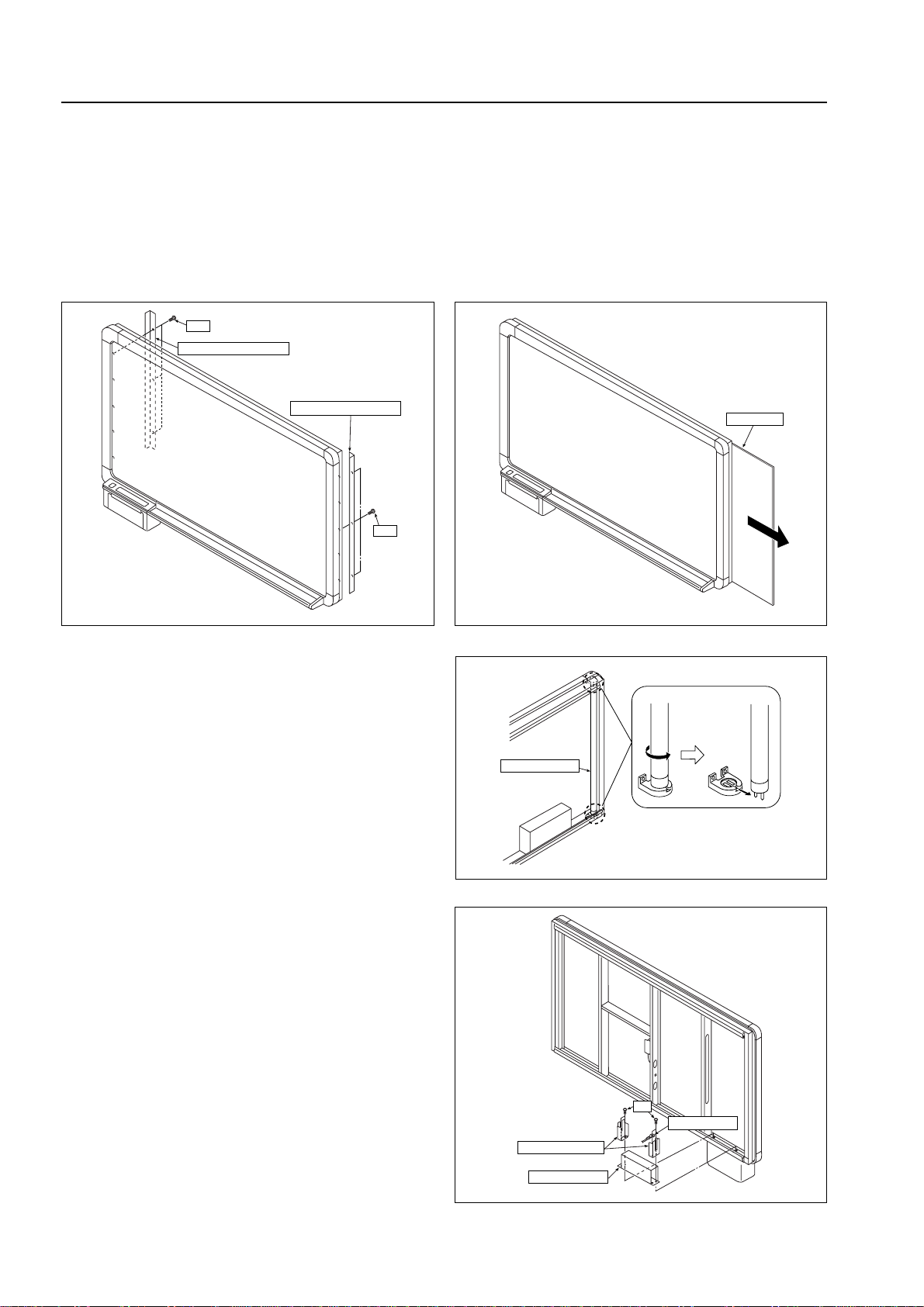

4. DISASSEMBLY AND ASSEMBLY ................................ 7

4-1. Caution ................................................................... 7

4-2. Tools needed .......................................................... 7

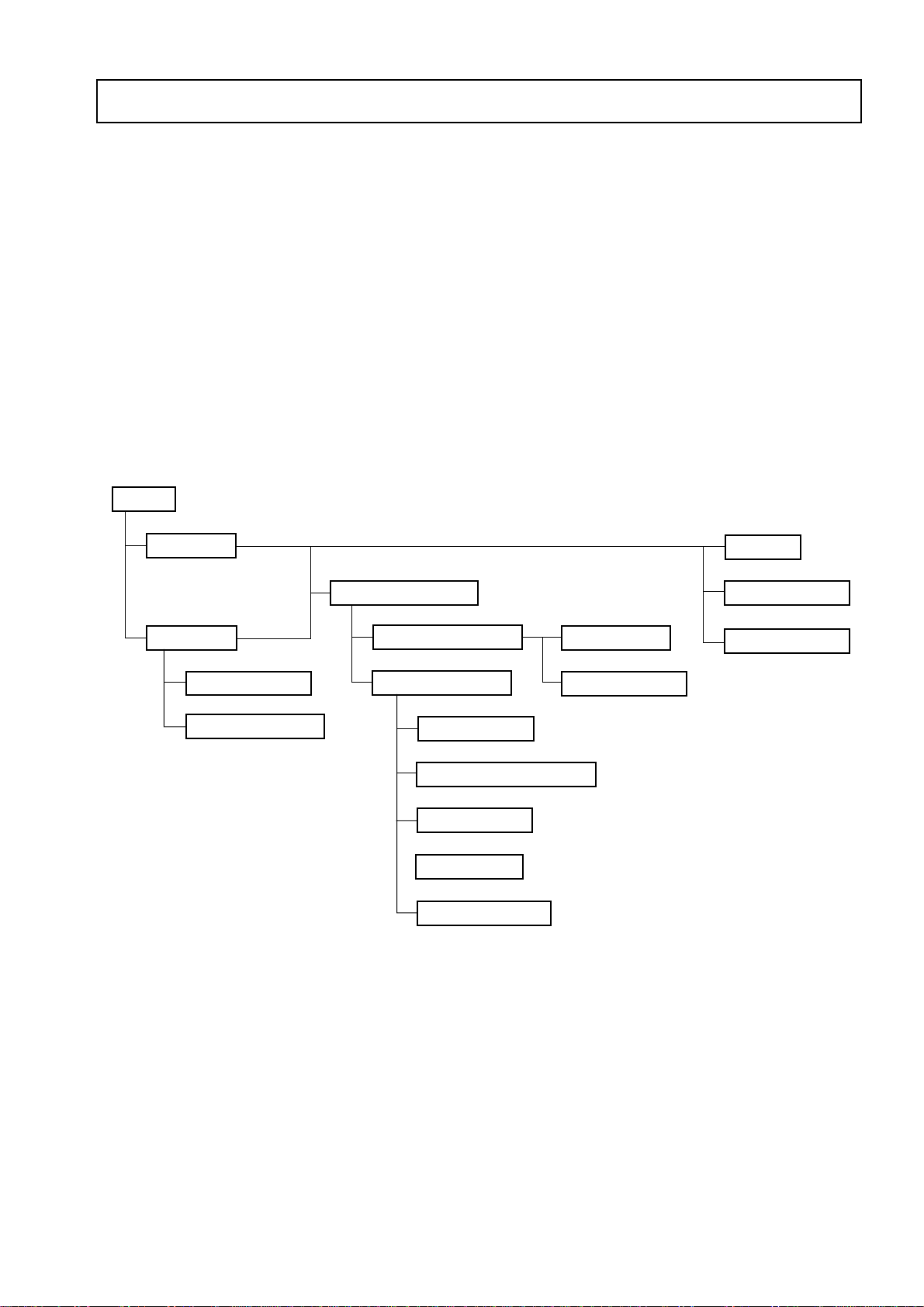

4-3. Disassembly and Assembly Order ......................... 7

4-4. Disassembly and Assembly.................................... 8

5. ADJUSTMENT............................................................. 15

5-1. Quick Calibration .................................................. 15

5-2. Calibration ............................................................ 16

5-3. CCD Unit Adjustment ........................................... 17

5-4. TensionAdjustment of Timing Belt ....................... 22

6. CABLE AND CABLE CONNECTION ........................... 23

CONTENTS

7. PARTS LIST .................................................................. 24

7-1. BOARD UNIT SECTION (BF-041S)..................... 24

7-1. BOARD UNIT SECTION (BF-041W).................... 26

7-2. FRAME COVER SECTION (BF-041S) ................ 28

7-2. FRAME COVER SECTION (BF-041W) ............... 29

7-3. SHEET FRAME SECTION (BF-041S) ................. 30

7-3. SHEET FRAME SECTION (BF-041W) ............... 31

7-4. BOARD FRAME SECTION (BF-041S) ................ 32

7-4. BOARD FRAME SECTION (BF-041W) ............... 34

7-5. PRINTER UNIT SECTION 1(BF-041S/W) ........... 36

7-6. PRINTER UNIT SECTION 2 (BF-041S/W) .......... 38

7-7. STAND SECTION ............................................... 40

7-8. WALL MOUNTING SECTION .............................. 42

7-9. ACCESSORIES SECTION................................... 43

7-10. PACKING SECTION .......................................... 44

7-11. SCREWS & WASHERS SECTION .................... 46

8. SERVICE NOTE .......................................................... 47

8-1.

Replacement Procedure of Dedicated Recording Paper .....

47

8-2. Updating the Firmware ......................................... 48

8-3. Thermal Head Test ............................................... 51

9. REVISION HISTORY ................................................... 52