- 9 -

5.4 ANTI-CORROSION PROTECTION INSTRUCTIONS

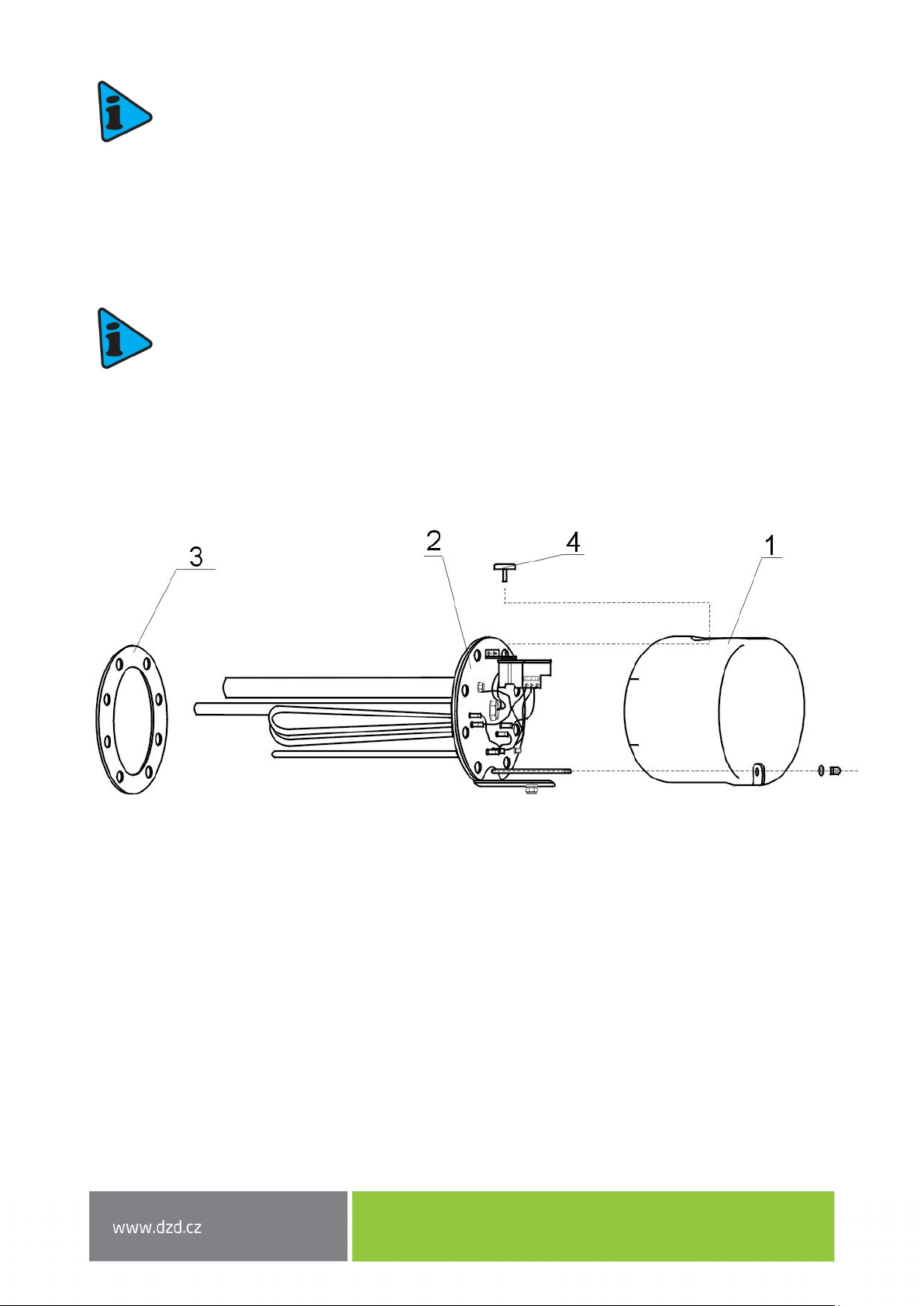

Heating unit maintenance involves checking and exchanging of the anode rod that is only contained

in outputs from 2.5 to 6 kW.

Magnesium anode sets the electric potential inside the tank to a level that limits boiler tank corrosion.

Theoretically, its lifetime is calculated to two years of operation; however, it changes based on water

hardness and chemical composition at the place of use. Anode rod check and possible replacement

is recommended every two years of operation. Based on anode wear, set the time of the next check.

We recommend you do not underestimate the importance of this additional protection of the boiler tank.

Anode rod exchange method:

1. Turn off the boiler control voltage;

2. Empty the boiler water.

Procedure: Close the water entry valve to the boiler

Open the hot water valve on the mixing tap

Open the boiler drain tap

3. The anode is screwed onto the heating unit

4. Unscrew the anode using adequate wrench

5. Pull the anode out and follow reversed steps to install a new one

6. During the assembly, make sure the ground wire is connected properly; it is essential for proper

anode function

7. Fill the boiler with water

5.5 ACCUMULATOR CONNECTION TO THE PRESSURIZED WATER

MAIN

Accumulator assembly, connection, and use instructions must be followed.

Connection to the Pressure System

If inadequate and non-functional fittings are used and the operational pressure exceeded, the warranty

is cancelled.

Water main connection may only be implemented via a diaphragm safety valve or a diaphragm safety

combination. Safety valve combination consists of a closing valve, pressure reducing valve, test valve,

backflow valve, overload valve with compensation circulation, and a drain valve. This combination is built

in between the cold water inlet and cold water inlet to the reservoir.