- 5 -

4OPERATION PRECONDITIONS

The connection of a built-in electric flange unit must follow the data on the plate (operation

pressure, heating time, el. voltage). Connecting to the electrics must follow the scheme on the

inside of the protective cover.

Aside from the electric regulations, the conditions of local distribution and water supply plants,

as well as assembly and operation conditions, must be followed.

If the water is really hard, we recommend installation of water treatment filters preventing

the scale occurrence.

These heating elements are suitable for enameled accumulators, double casing tanks, or accumulators

coated with either plastic or zinc; they are also suitable for ribbed exchangers. Combination with chromium–

nickel vessels is problematic, and therefore not recommended (see par. 5.3). All elements are suitable

for heating drinkable and heating water with operating pressure within 10 bar.

5ASSEMBLY AND SAFETY INSTRUCTIONS

5.1 GENERAL INSTRUCTIONS

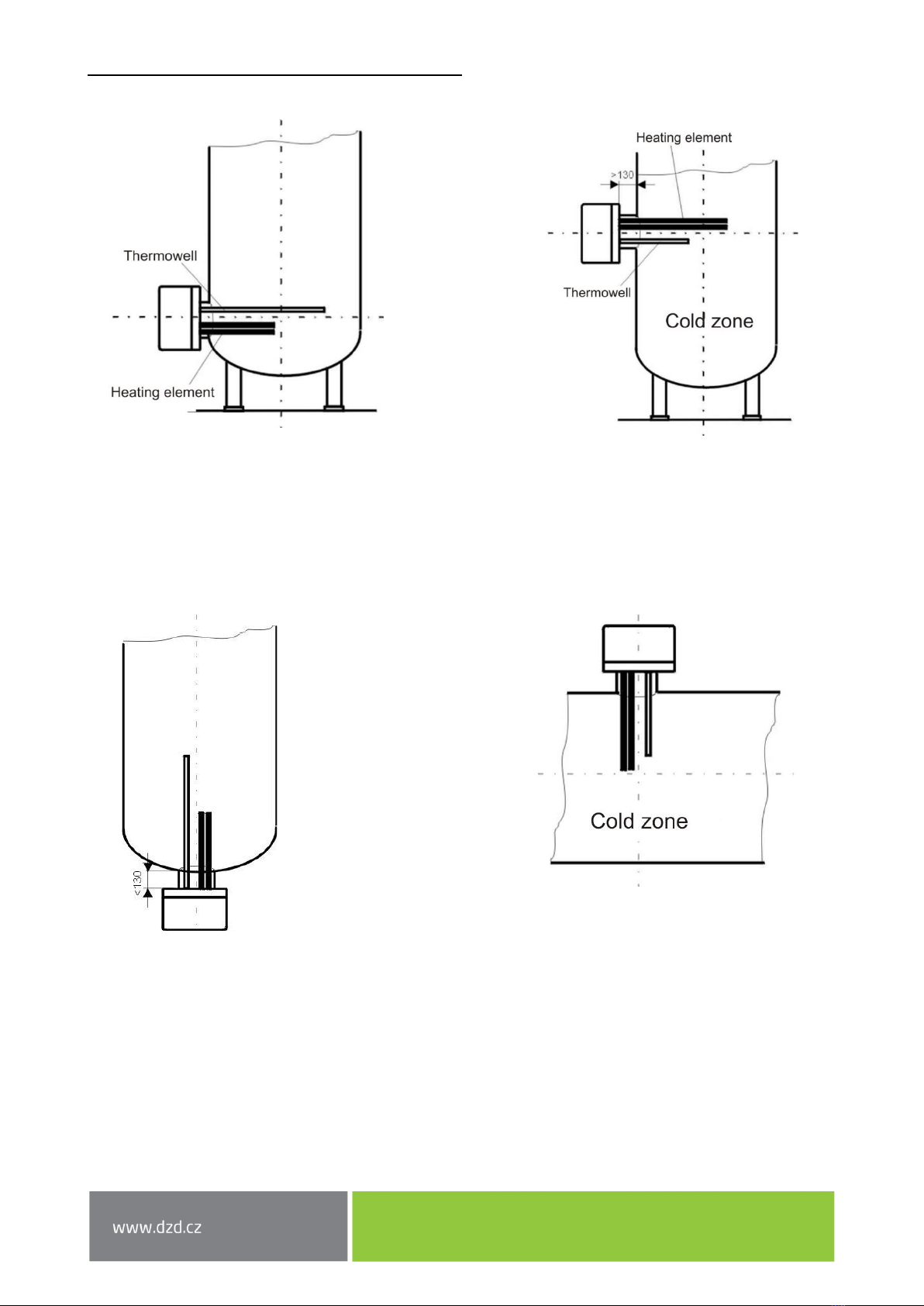

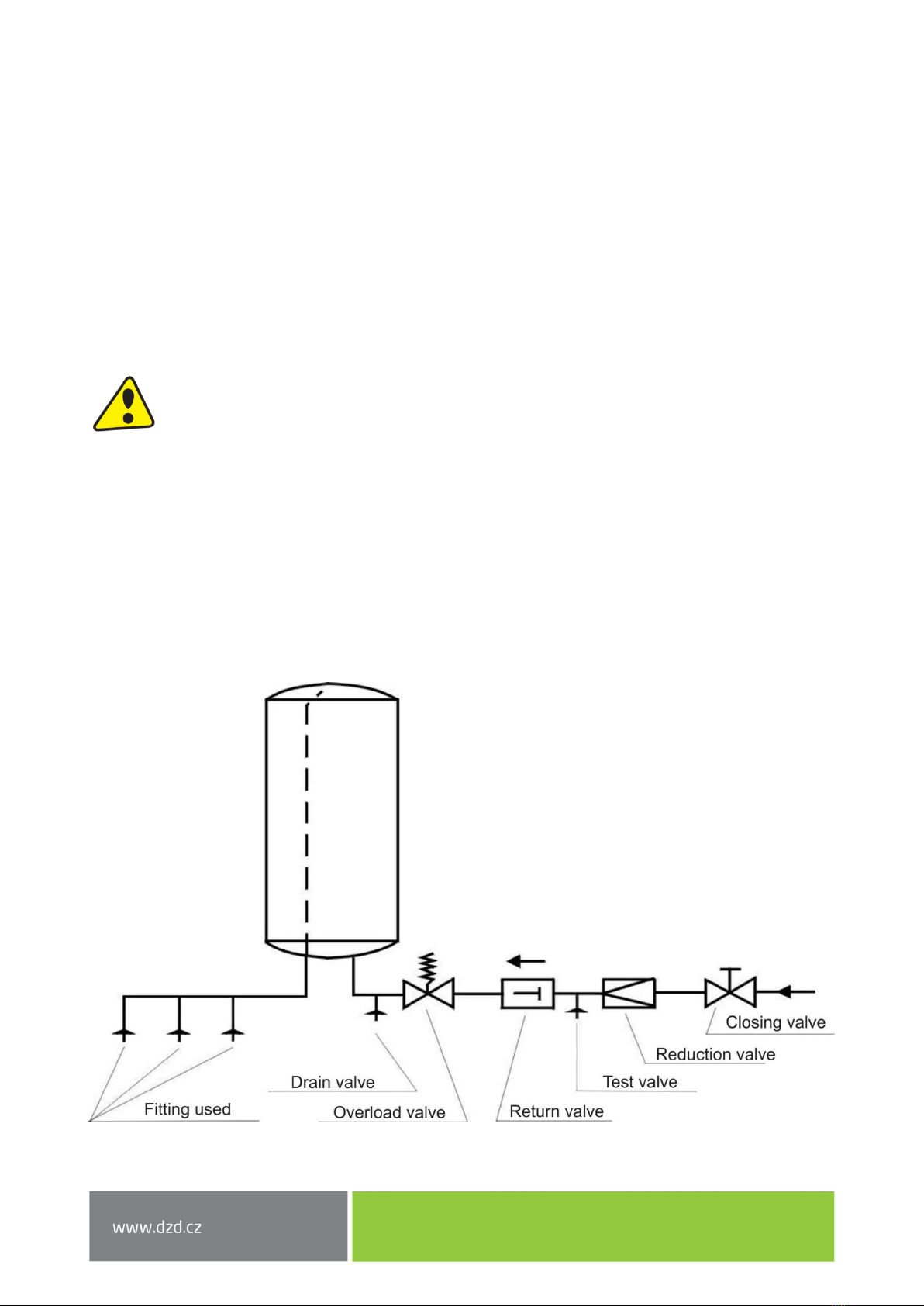

During operation, both the heating element and the anode rod must be under water. Necessary thermal flow

of heated water must not be prevented. The heating unit is equipped with a safety fuse preventing further

water heating at maximum temperature of approx. 95 °C. It is therefore necessary to select suitable

connecting components (pipelines, safety valve combination) that, in case of thermostat defect, resist

the max. temperature of 110 °C.

Both the assembly and installation must be implemented by authorized people only.

Both electric and water installation must follow and meet requirements and regulations

relevant in the country of use.