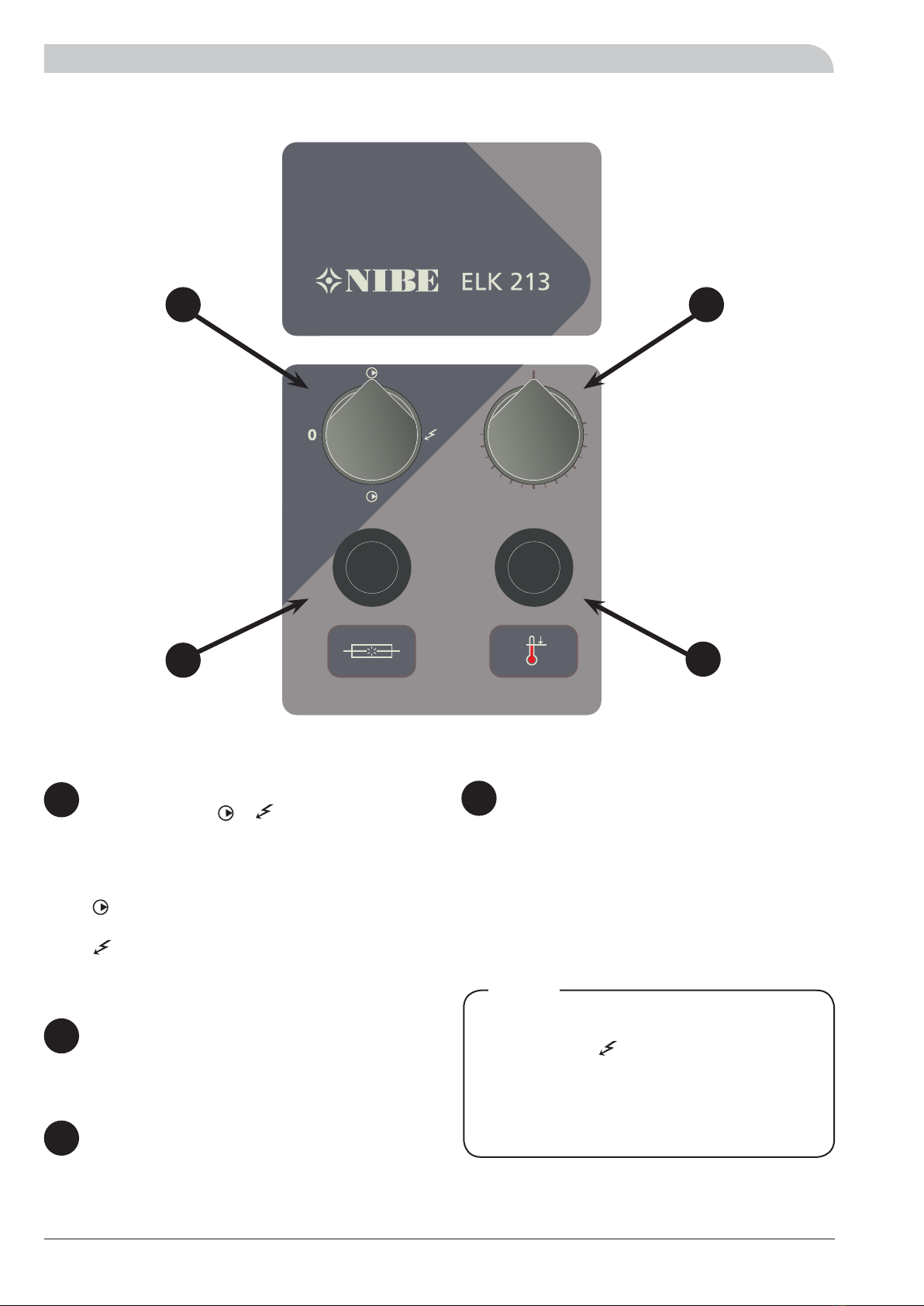

5NIBE ELK 213

For the Installer

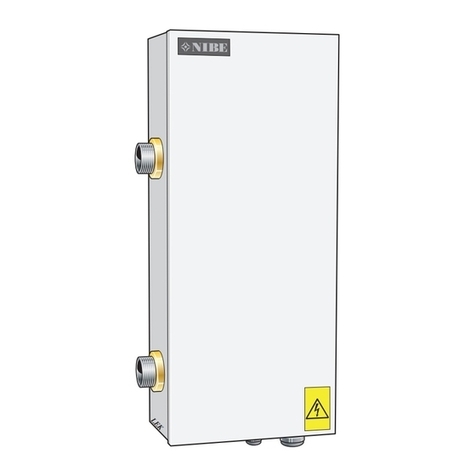

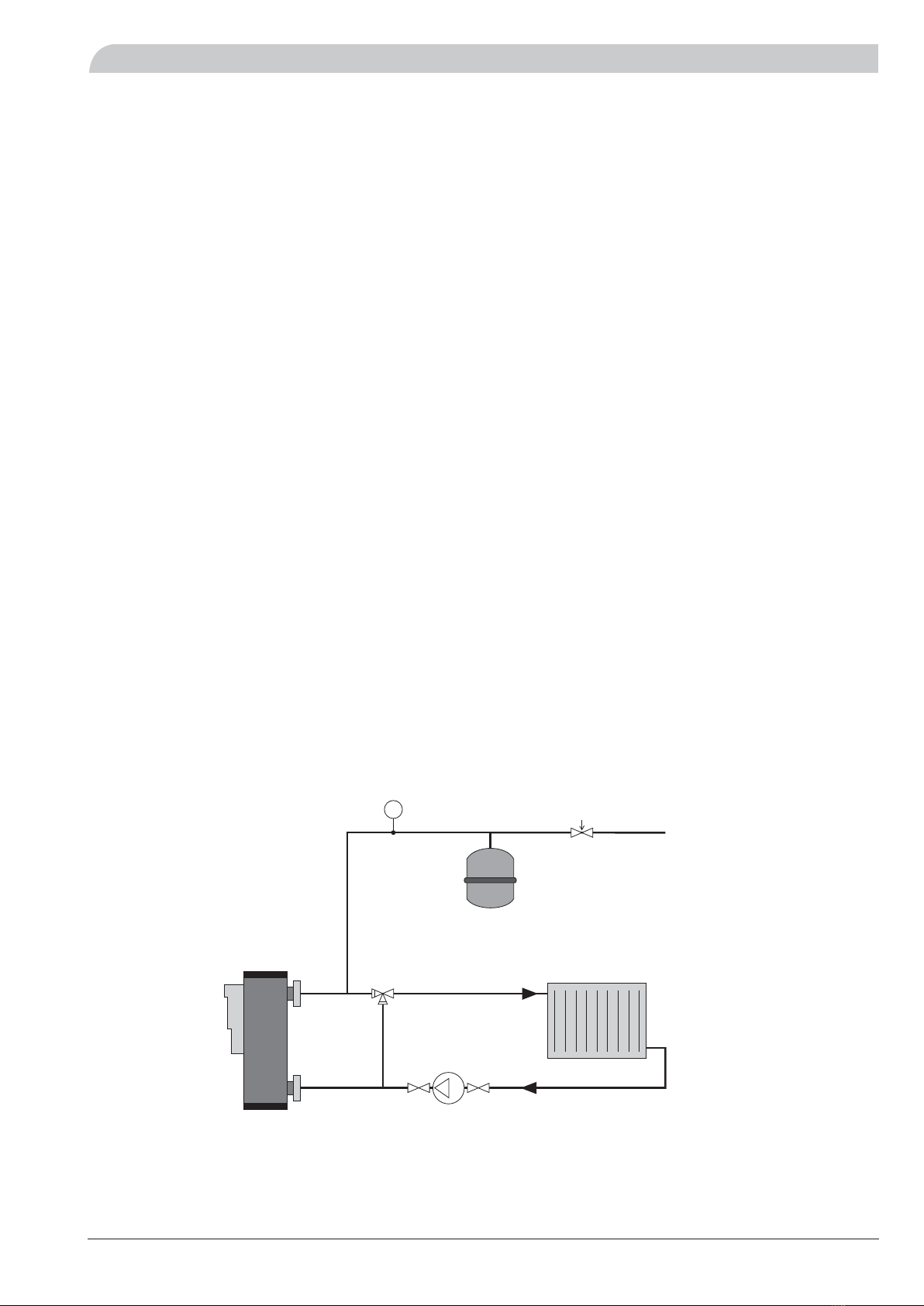

Pipe installation

Pipe installation

500

200

Connection

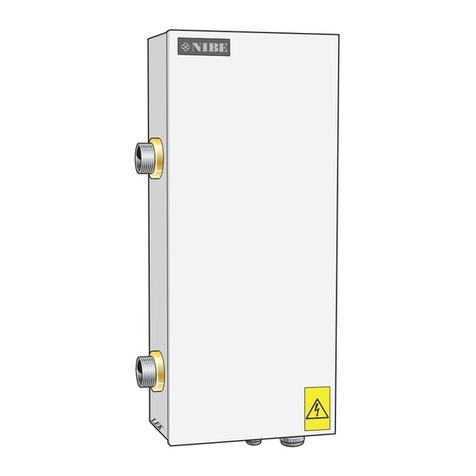

Install the immersion heater so that external heating does

not cause overheating, for example, in front of the hearth

door (to prevent flames blowing out) or next to the flue

(to prevent damaging heat radiation). A suitable location

is normally at the side of the boiler, directly on the double

jacketed heater’s flanges or similar location.

The pipe installation must be carried out in accordance

with current norms.

The immersion heater is designed for upright installation.

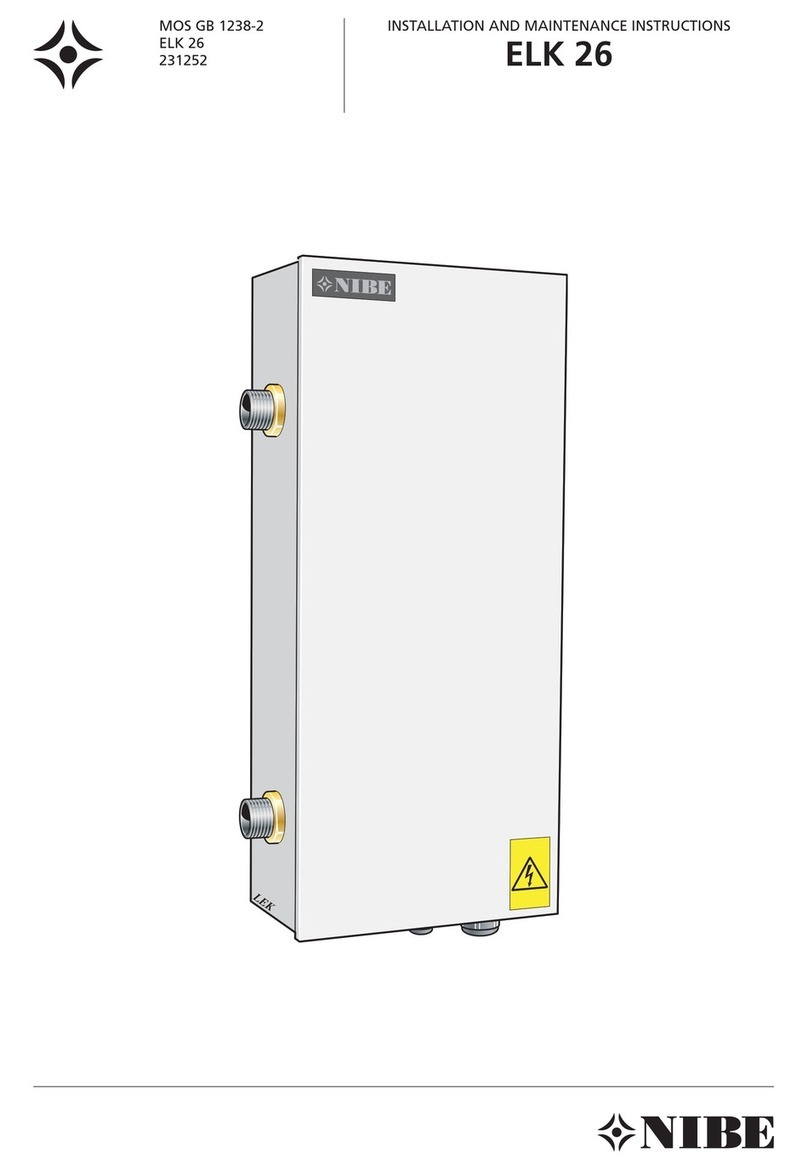

For servicing, immersion heater replacement, miniature

circuit breaker or temperature limiter resetting as well as

draining, 200 mm of space is required in front of the heat-

er’s control panel and 500 mm above the heater (see fig.).

If the above stated spaces cannot be achieved, detachable

connections must be used.

Circulation pump must be used. Pipe dimensions can then

be reduced to R25 with welded sleeves. The immersion

heater can be installed in double jacketed water heaters of

the SP or SPIS type, see installation option 3, (self-

circulation is required).

For follow-up operation, it is recommended to install a

thermometer between the immersion heater and the ap-

paratus that is to be heated, so that the outgoing water

temperature from the immersion heater can be read off.

As the immersion heater is installed on the existing wood

boiler and is solely responsible for the heating demand,

the flue should be sealed. This is most appropriately done

using a plastic bag filed with mineral wool, stuffed into the

hearth, as well as a cover on the opening of the flue.

In closed boiler installations, one of the Swedish Work

Environment Authority’s approved safety valves must be in-

stalled in an open connection with the boiler’s (immersion

heater’s) highest part, however, not directly on the boiler.

The connection line must rise continuously. The safety

valve must be “exercised” regularly, at least 4 times per

year by being opened and closed again quickly. The pres-

sure is then reset by filling with water.

Pipe line between heater and open expansion vessel must

be routed upwards and must not be able to be closed.

Draining

The system is most easily drained by installing a drainage

valve at the lowest point on the pipe installation. Draining

through such a valve leaves a small amount of water in

the immersion heater, which must therefore be drained

through the rain connection (17). If the installation is nor-

mally drained through the immersion heater’s drain con-

nection, install a suitable drainage valve.

The pipe work must be flushed

before the immersion heater is con-

nected, so that any contaminants do

not damage the components parts.

Note!

Before draining the immersion

heater,

cut the power supply.

Note!