General information for the installer

Function

Area of use for NIBE immersion heater is in combination with

NIBE ground source heat pumps and air/water heat pumps.

When the heating demand is greater then heat pump's ca-

pacity, the immersion heater connects automatically as addi-

tional heat. The electrical equipment is adapted to the heat

pump's function.

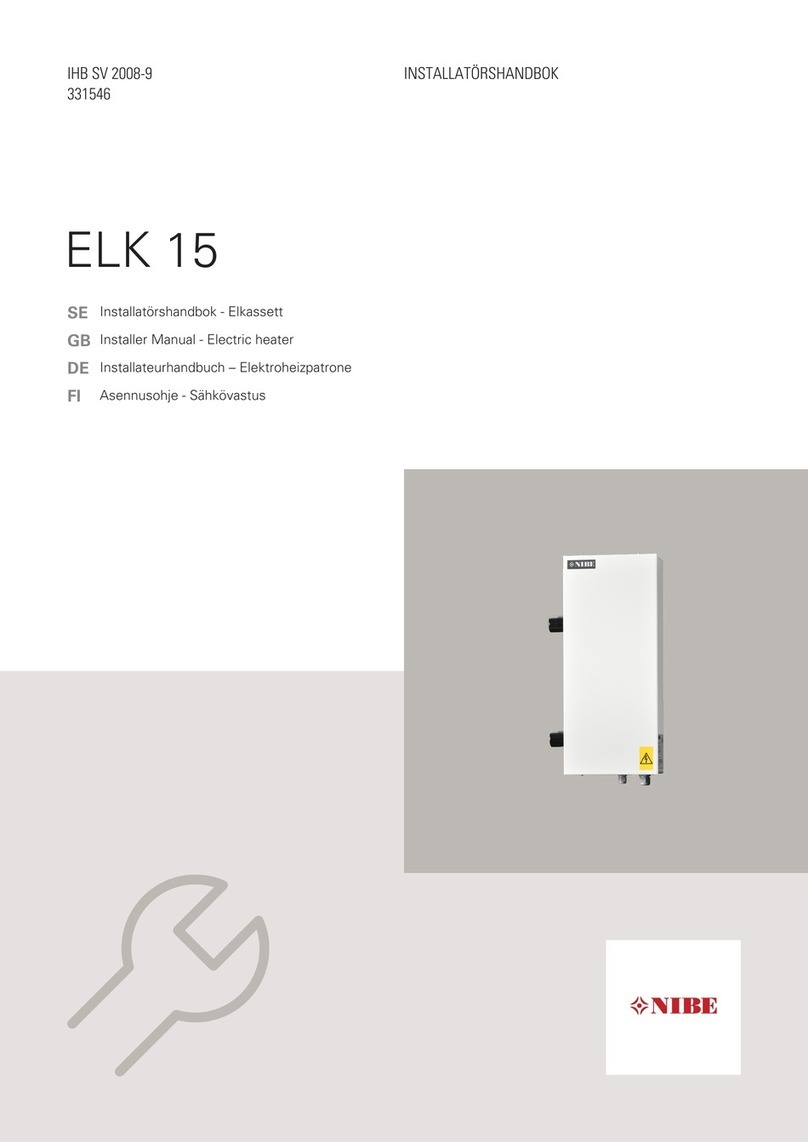

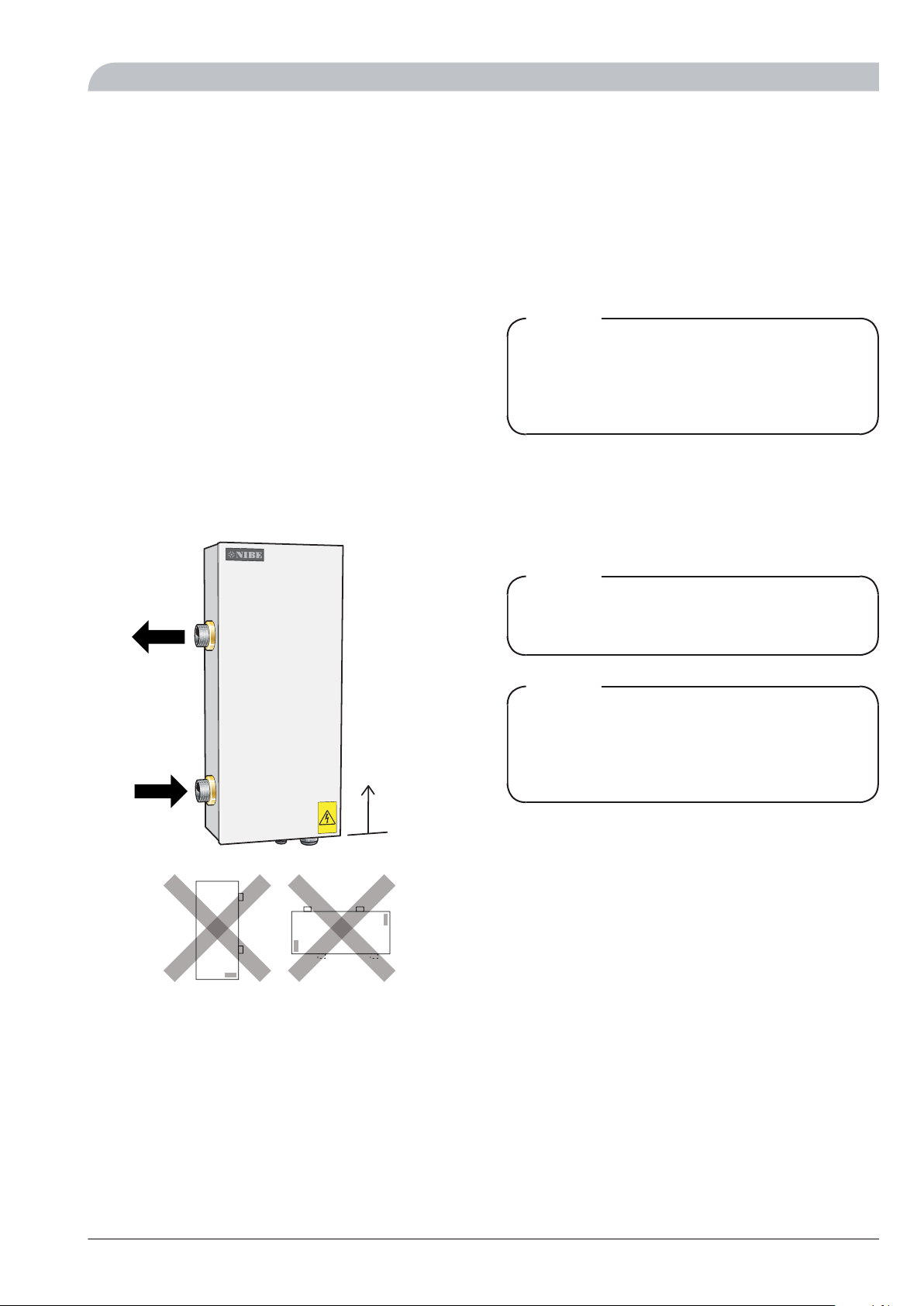

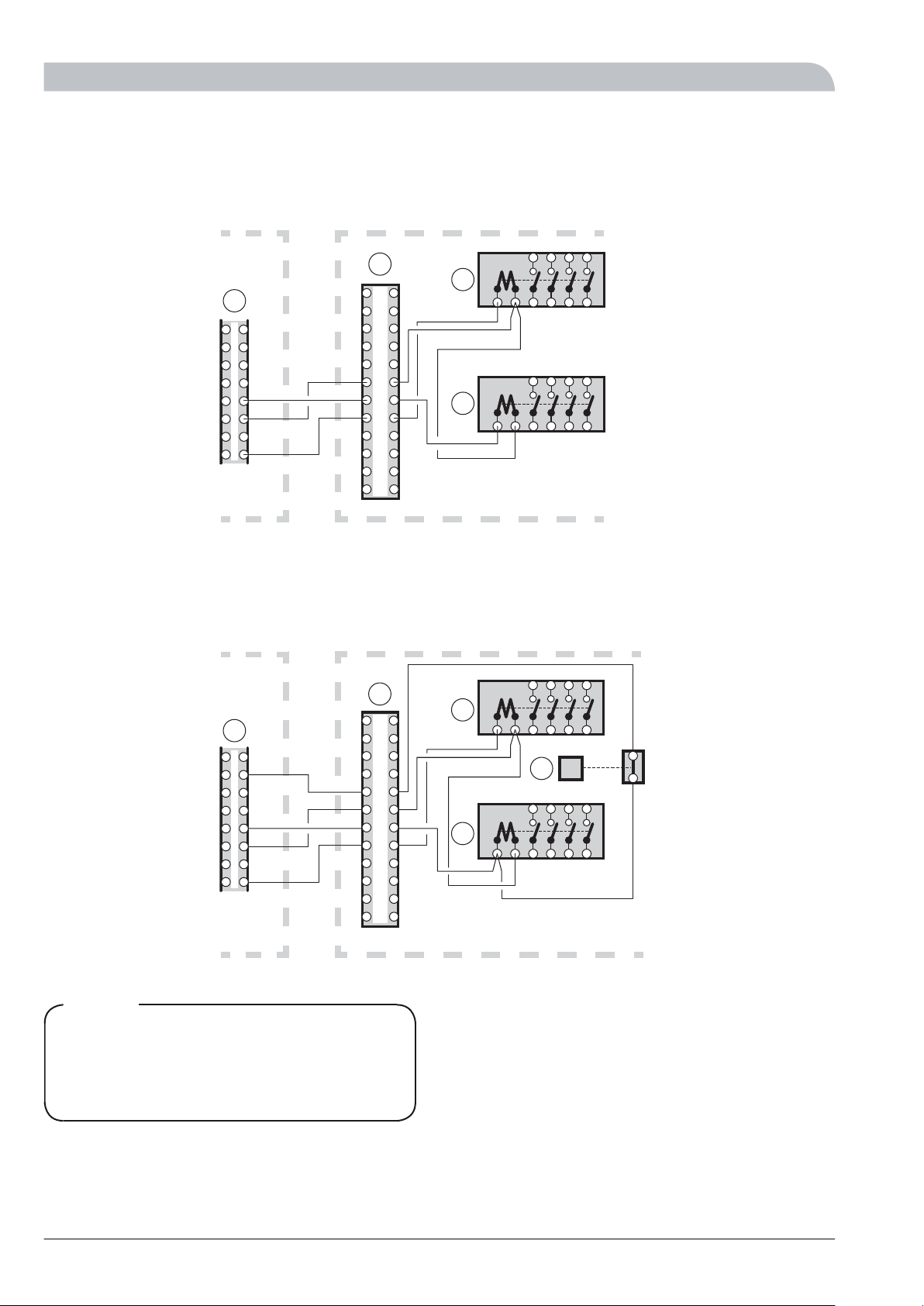

ELK 15 contains overheating protection and contactors to

externally regulate the two power steps, 5 and 10 kW. For

optimum function the outputs should be binary controlled,

i.e. 5, 10 and 15 kW.

If there is no operating voltage from the heat pump, the

largest power stage can be force controlled via thermostat.

See the wiring diagram.

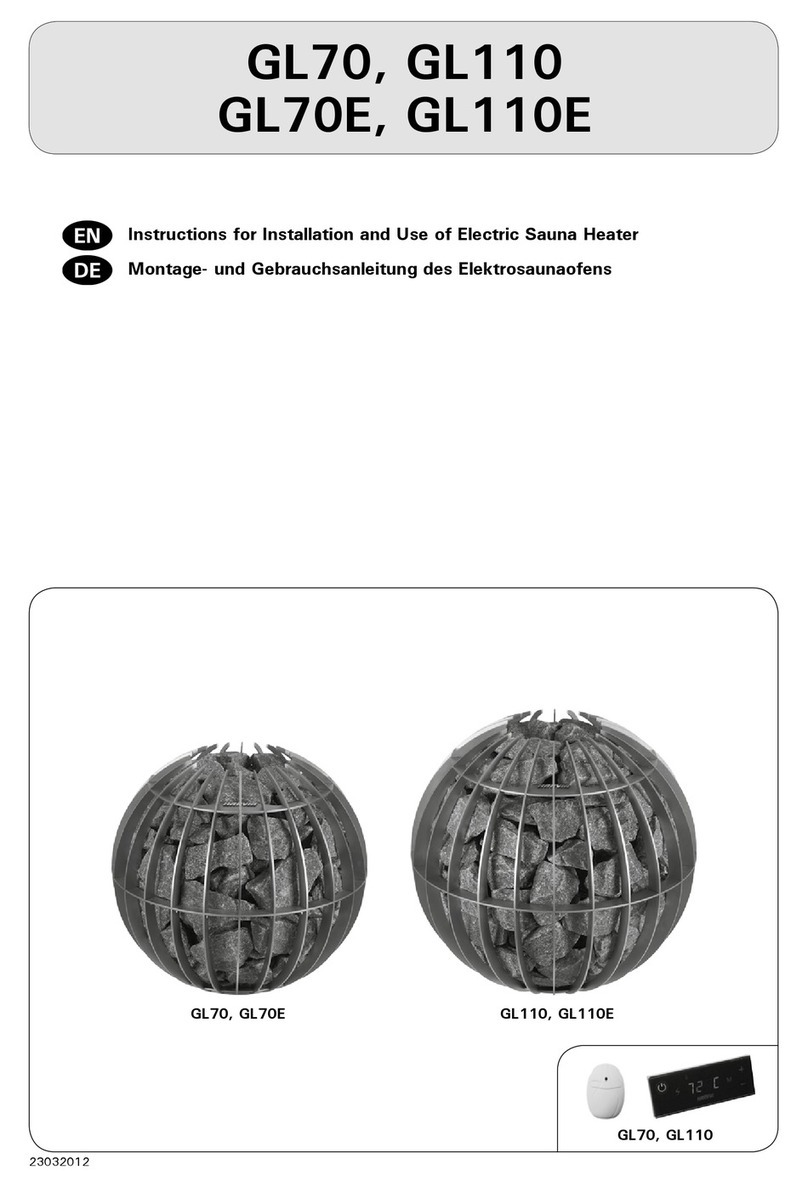

Pipe installation

The pipe installation must be carried out in accordance with

applicable standards.

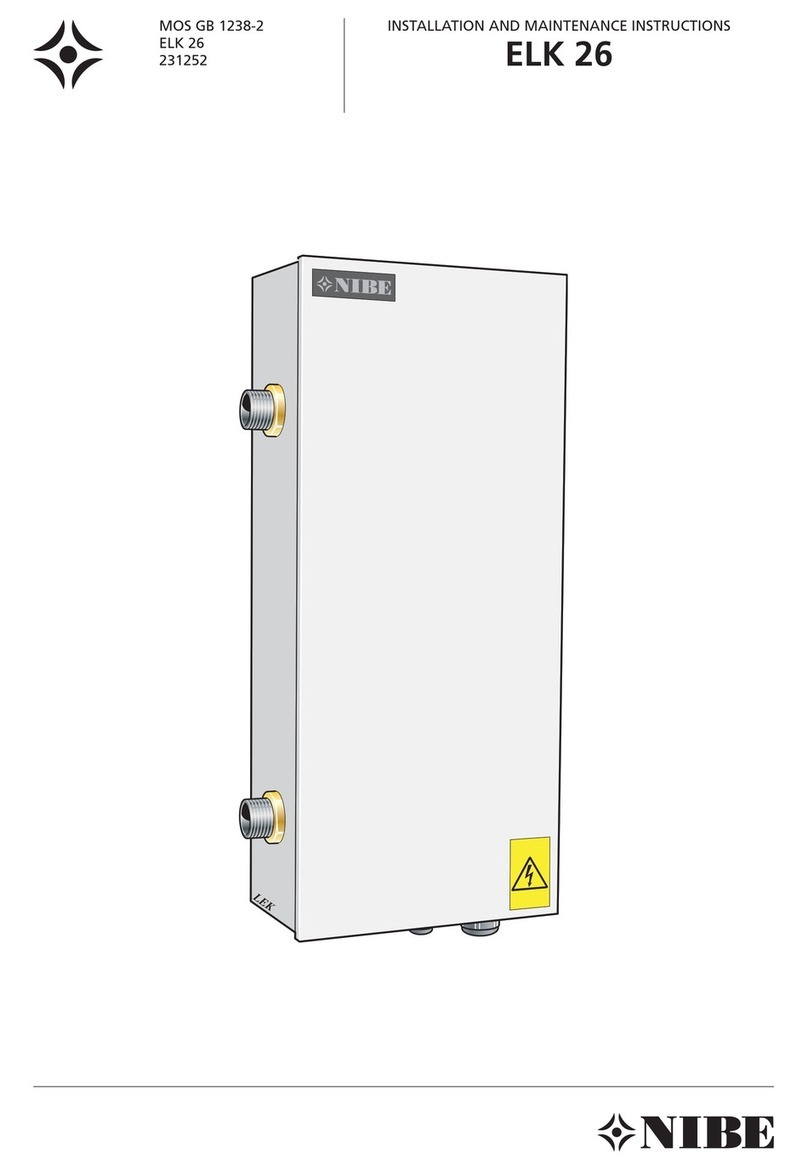

LEK

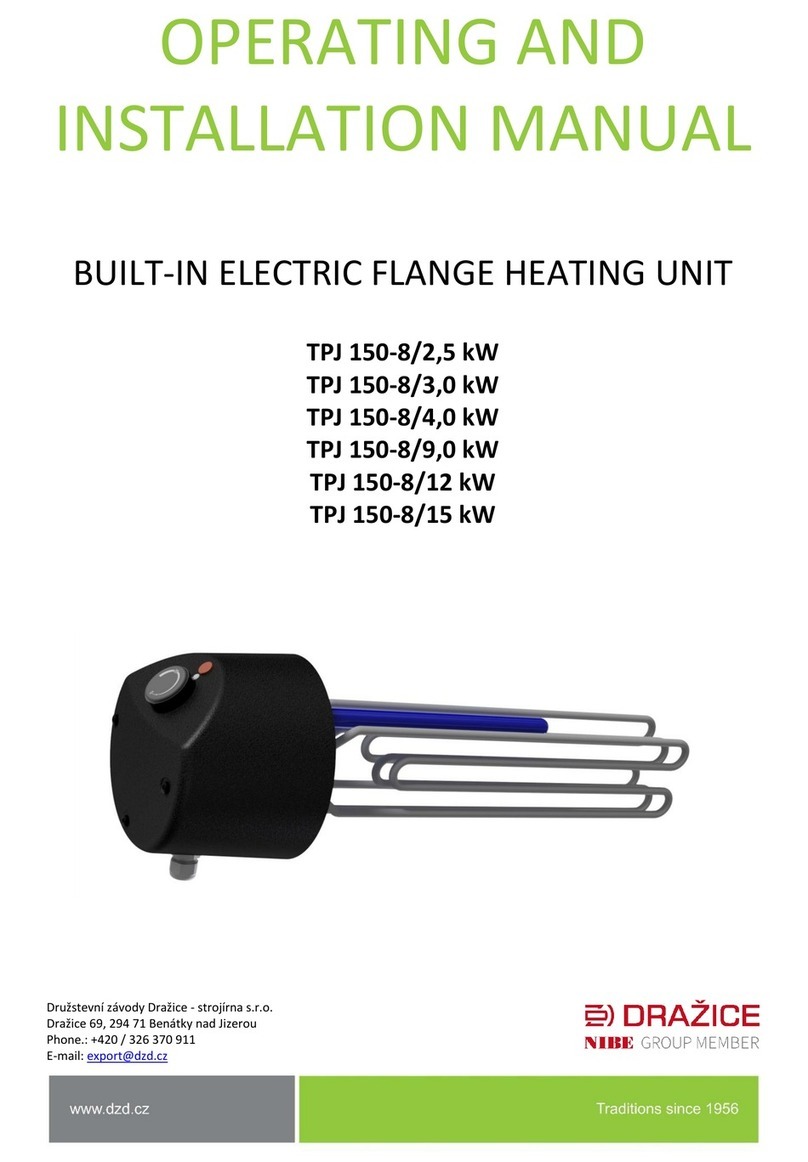

The immersion heater must be installed standing (see image

above). An area of 500 mm is required in front of the immer-

sion heater for service work. If this is not possible, detachable

connections should be used.

Circulation pump must be used to ensure the flow over the

immersion heater. If the heating system’s valves can close

the circulation completely, a by-pass must be installed to

prevent the flow through the immersion heater from being

stopped. When the unit is off, an approved safety valve must

be installed as well as a pressure expansion vessel. The safety

valves must be checked about four times a year. This is done

by quickly opening and closing the valves. The pressure is

reset by filling with water.

Electrical installation

ELK 15 must be installed via an isolator switch with a minim-

um breaking gap of 3 mm.

NOTE

Electrical installation and service must be carried out

under the supervision of a qualified electrician. Electric-

al installation and wiring must be carried out in accord-

ance with the stipulations in force.

Power supply

The electric heater must be supplied with 4x6mm

2cable,

3 x 400 V AC 50Hz, fused3x25A.

The cable for the operational supply must be 5 x 1,5 mm2.

NOTE

Reset the temperature limiter, it may have tripped

during transport.

NOTE

In the event of any servicing all electrical supplies must

be checked and disconnected. The immersion heater

can be supplied with voltage from connected heat

pump.

Draining

The system is most easily drained by installing a drain valve

to the lowest point of the piping. Draining via such a valve

leaves a small amount of water in the immersion heater,

which is therefore drained via drain connection (71). If the

unit is normally drained via the immersion heater's drain

connection, install a suitable drain valve.

5ELK 15

For the Installer

General information for the installer