Nikon NR-5500 Operating instructions

Other Nikon Measuring Instrument manuals

Nikon

Nikon Aculon User manual

Nikon

Nikon PROSTAFF 7 User manual

Nikon

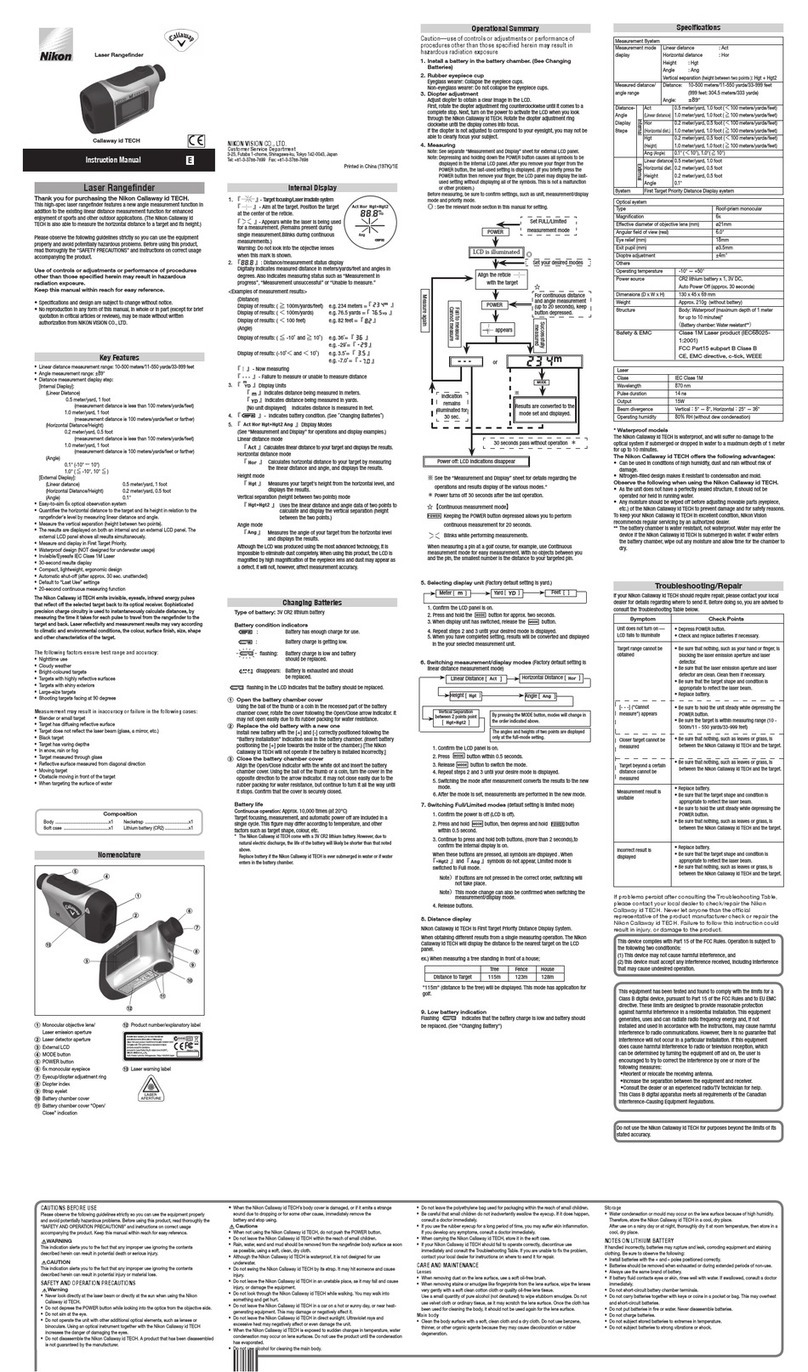

Nikon Callaway LR550 User manual

Nikon

Nikon LASER 50 User manual

Nikon

Nikon Cool Shot 40 User manual

Nikon

Nikon COOLSHOT PRO II STABILIZED User manual

Nikon

Nikon Prostaff 1000i User manual

Nikon

Nikon Laser 550 User manual

Nikon

Nikon COOLSHOT User manual

Nikon

Nikon PROSTAFF 3i User manual

Nikon

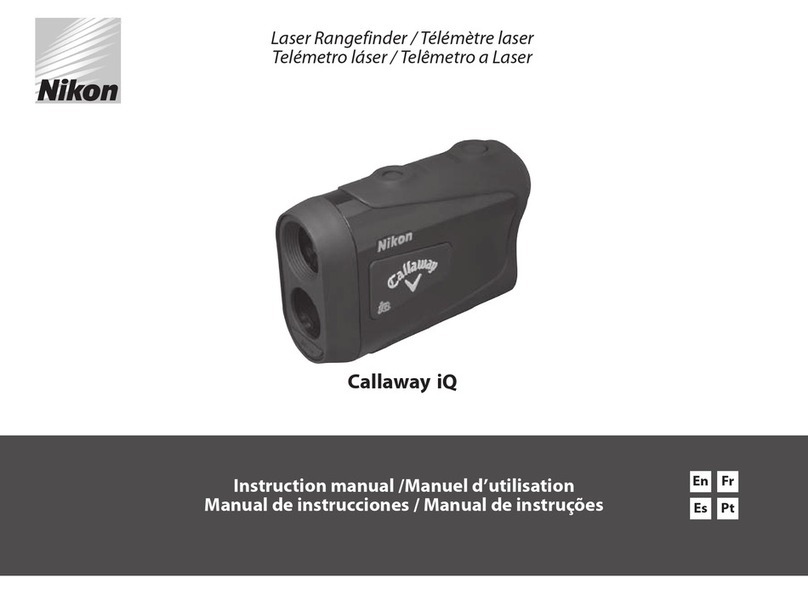

Nikon Callaway iQ User manual

Nikon

Nikon ProStaff LASER 440 User manual

Nikon

Nikon 50i User manual

Nikon

Nikon Nivo 2.C User manual

Nikon

Nikon Total Station DTM-322 User manual

Nikon

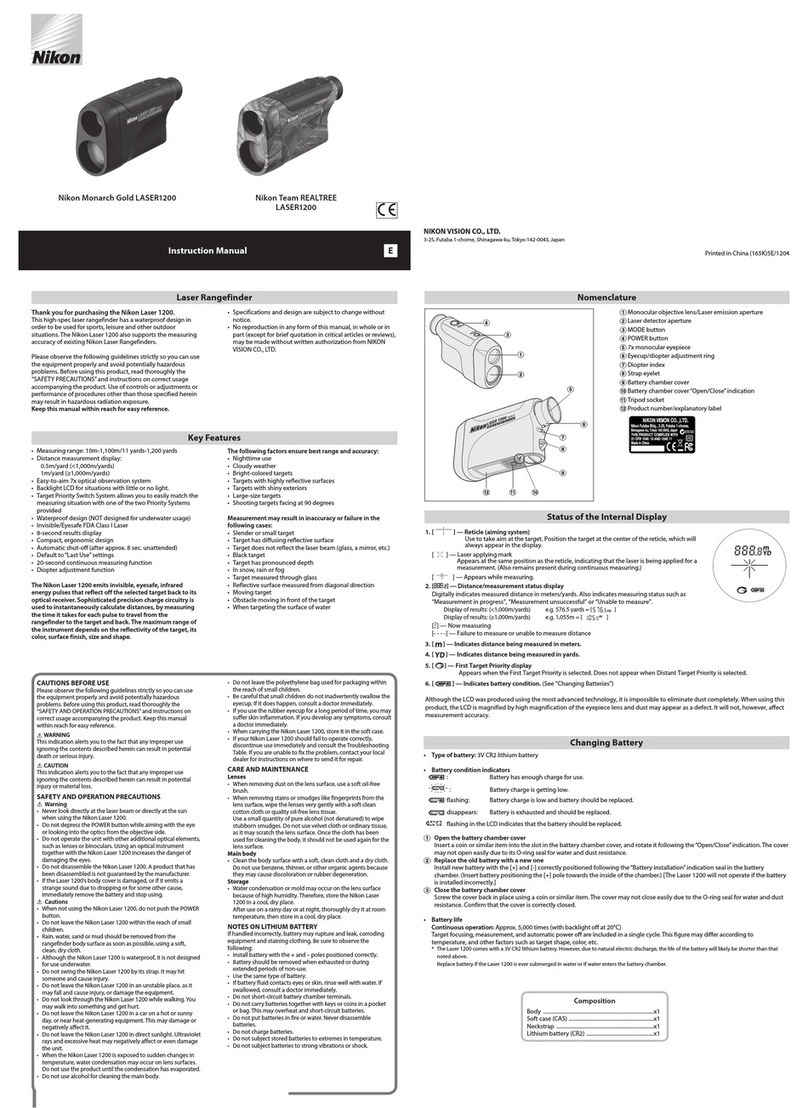

Nikon 7487 - Team Realtree Laser 1200 Rangefinder User manual

Nikon

Nikon CoolShot Pro Stabilized User manual

Nikon

Nikon HQA46480 User manual

Nikon

Nikon Callaway XHOT User manual

Nikon

Nikon Callaway iQ User manual