Nikon SC User manual

Other Nikon Microscope manuals

Nikon

Nikon SMZ1500 User manual

Nikon

Nikon YS100 User manual

Nikon

Nikon A1 User manual

Nikon

Nikon SMZ800N User manual

Nikon

Nikon Live Cell 2 User manual

Nikon

Nikon eclipse Ti-U/B User manual

Nikon

Nikon eclipse lv150 User manual

Nikon

Nikon 50i User manual

Nikon

Nikon LABOPHOT-POL User manual

Nikon

Nikon LABOPHOT2-POL User manual

Nikon

Nikon Optiphot 66 User manual

Nikon

Nikon ECLIPSE E200 POL User manual

Nikon

Nikon OPTIPHOT-2 User manual

Nikon

Nikon LABOPHOT-POL User manual

Nikon

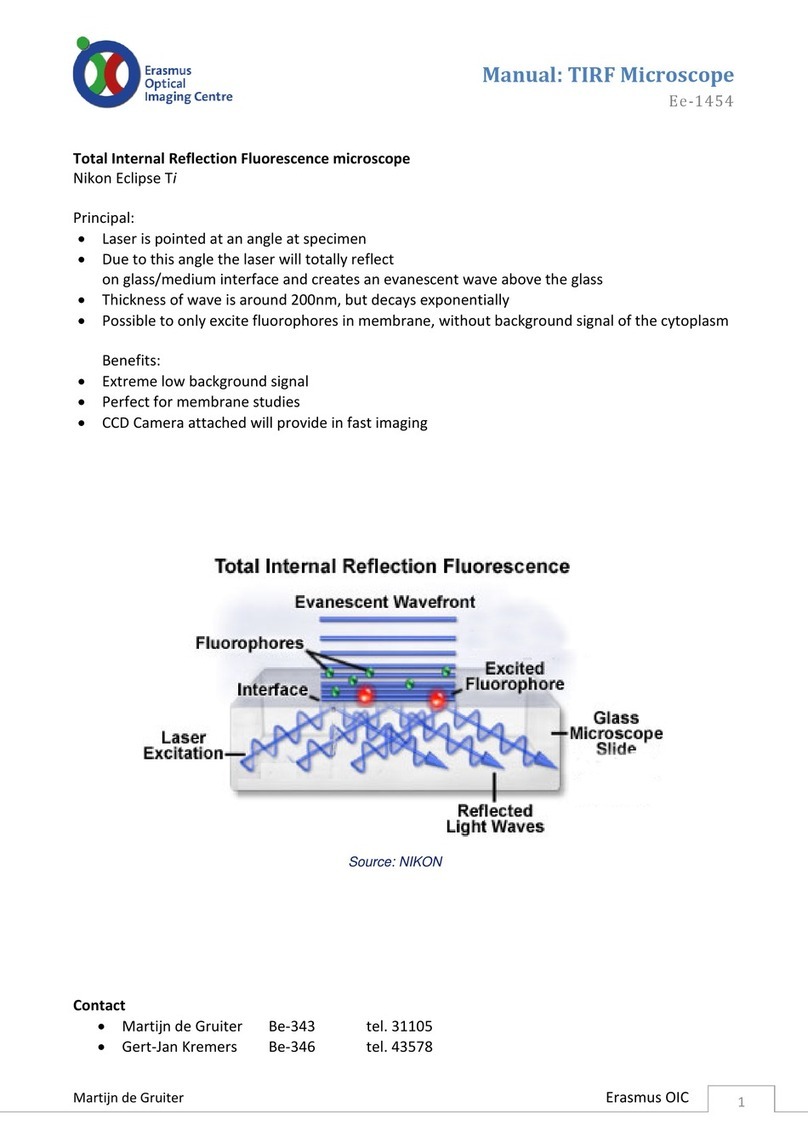

Nikon Eclipse Ti TIFT 1454 User manual

Nikon

Nikon SMZ-2 User manual

Nikon

Nikon T1-FM User manual

Nikon

Nikon Elcipse TE2000 User manual

Nikon

Nikon E800 User manual

Nikon

Nikon eclipse E200 User manual