Norac UC4+ NITRO Miller 3200 Series User manual

Table of contents

Other Norac Controllers manuals

Norac

Norac UC4+ User manual

Norac

Norac UC4 Total Control User manual

Norac

Norac U5 User manual

Norac

Norac UC4 Plus Rogator 64 Series User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac FLEXI-COIL 67 Series User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4+ Guide

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC4 Plus Rogator 64 Series User manual

Norac

Norac UC4+ Roll Control User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Popular Controllers manuals by other brands

National Instruments

National Instruments PXIe-8861 user manual

Inficon

Inficon VGC083A operating manual

Mitsubishi Electric

Mitsubishi Electric MELSEC FX3U-232ADP-MB user manual

Barthelme

Barthelme CHROMFLEX III manual

Johnson Controls

Johnson Controls M9220-GG-3 Series installation guide

MULTILANE

MULTILANE QSFP-DD manual

Ries

Ries MicroNova ADR 230 Series manual

Rexnord

Rexnord Thomson Electrak XD installation manual

HEIDENHAIN

HEIDENHAIN ND 1200 - V2.17 GUIDE Quick reference guide

enphase

enphase IQ Combiner 3 Quick install guide

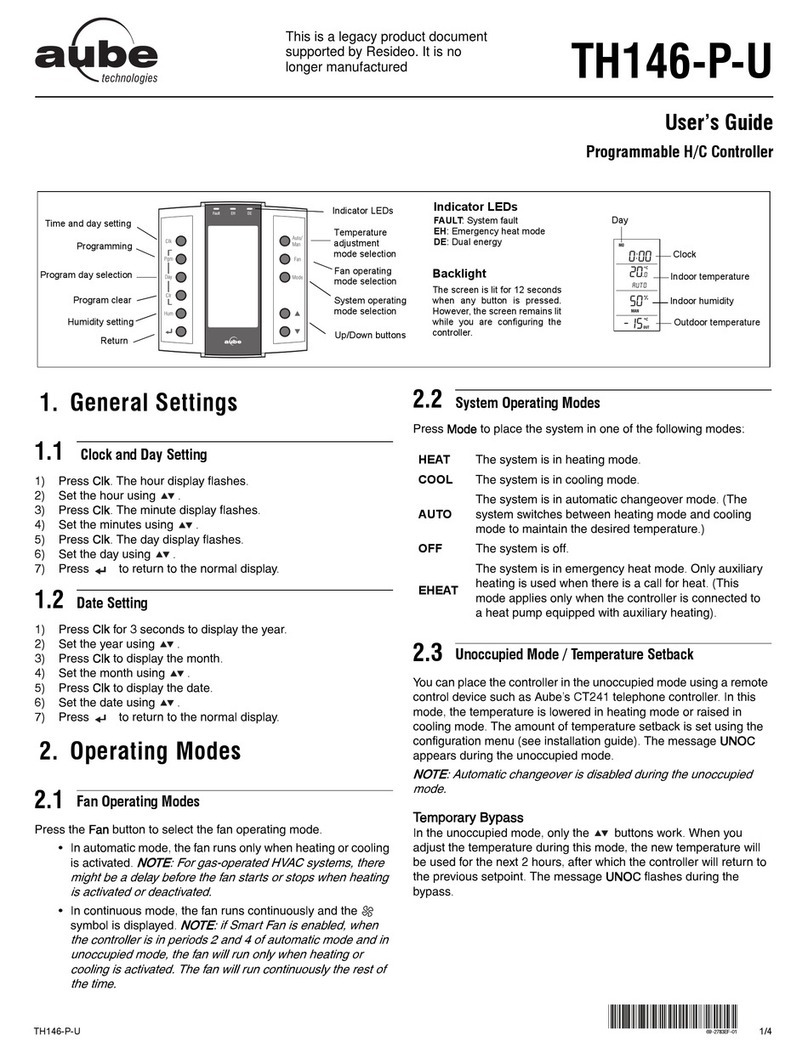

Aube Technologies

Aube Technologies TH146-P-U user guide

HETRONIC

HETRONIC MEC-HL COMPACT installation manual