Norac UC4 Plus Rogator 64 Series User manual

Other manuals for UC4 Plus Rogator 64 Series

5

Table of contents

Other Norac Controllers manuals

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac Gregson Maverick 120 Series User manual

Norac

Norac UC4+ 1200/1600 User manual

Norac

Norac UC4+ Case 44 Series User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4 Plus Rogator 74 Series User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ Guide

Norac

Norac UC4+ User manual

Norac

Norac UC4+ New Navigator 2007+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4+ Hardi OEM User manual

Norac

Norac UC4+ User manual

Popular Controllers manuals by other brands

motorherz

motorherz VR-2200 v.2 Operation manual

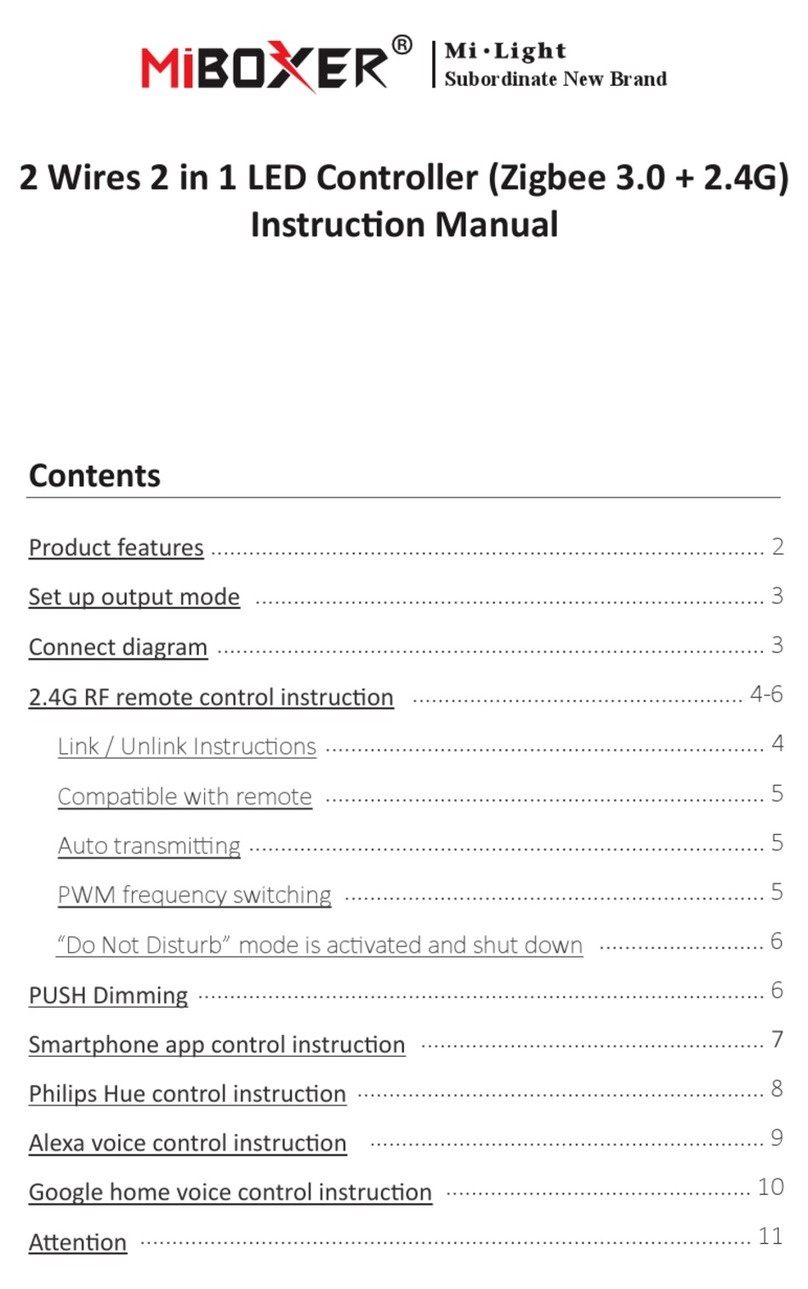

Mi-Light

Mi-Light MiBOXER LC2-ZR instruction manual

Trio

Trio Flex-6 Nano P601 quick start guide

Mitsubishi Electric

Mitsubishi Electric MELSEC FX2N Beginners manual

Mitsubishi

Mitsubishi MELFA CR1D instruction manual

Dometic

Dometic Enerdrive EN43510 owner's manual