1 Intended use

The bus node type CTEU-EP is intended exclusively for use

as a participant in EtherNet/IP or Modbus TCP networks.

The bus node may only be used in its original status

without unauthorised modifications and only in perfect

technical condition.

The specified limit values must be observed here.

The product is intended for use in industrial environ

ments. Outside of industrial environments, e.g. in com

mercial and mixed-residential areas, actions to suppress

interference may have to be taken.

Note...................................

Comply with the legal rules and regulations and

standards, rules of the testing organisations and

insurance companies and national specifications

applicable for the location.

Note...................................

Detailed information on commissioning is provided in

the documentation for the higher-order control system.

Information on EtherNet/IP:

èwww.odva.org

Information on ModbusTCP:

èwww.modbus.org

Information about products from Festo:

èwww.festo.com/sp

Note...................................

EtherNet/IP®, MODBUS®, ROCKWELLAUTOMATION®,

STUDIO5000®are registered trademarks of the re

spective trademark owners in certain countries.

For all available product documentation

èwww.festo.com/pk

Training of specialized personnel

The product may only be commissioned by trained spe

cialists in control and automation technology who are

familiar with:

– mounting, installation, operation and diagnostics of

control systems, networks and fieldbus systems

– the applicable regulations for accident prevention and

occupational safety

– the documentation for the product.

Service

Consult your local Festo repair service if you have any

technical problems.

2 Safety instructions

Prior to any assembly or installation work, switch off

power supplies, disconnect the compressed air supply

and vent the pneumatics.

For the electrical power supply, only use PELV circuits in

accordance with IEC60204-1/EN60204-1.

Observe the handling specifications for electrostatically

sensitive devices.

Use cover caps to seal unused connections to achieve

the required degree of protection.

Always ensure that the connection technology being

used has the required degree of protection.

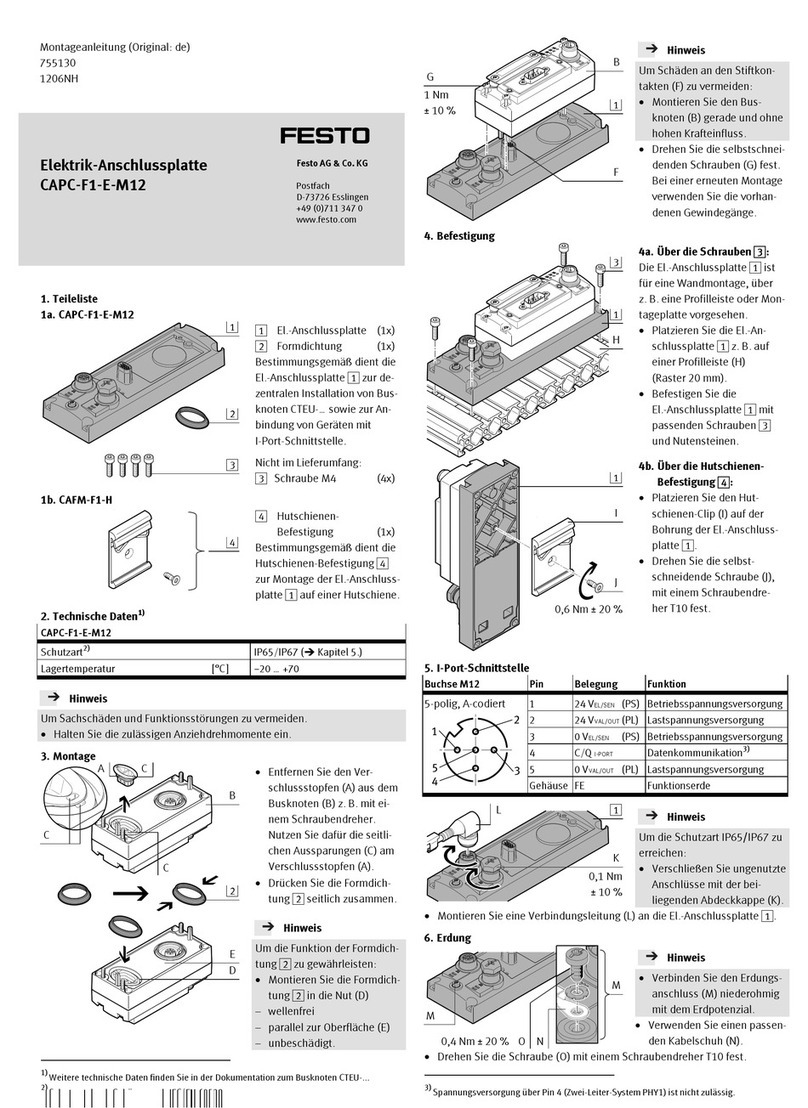

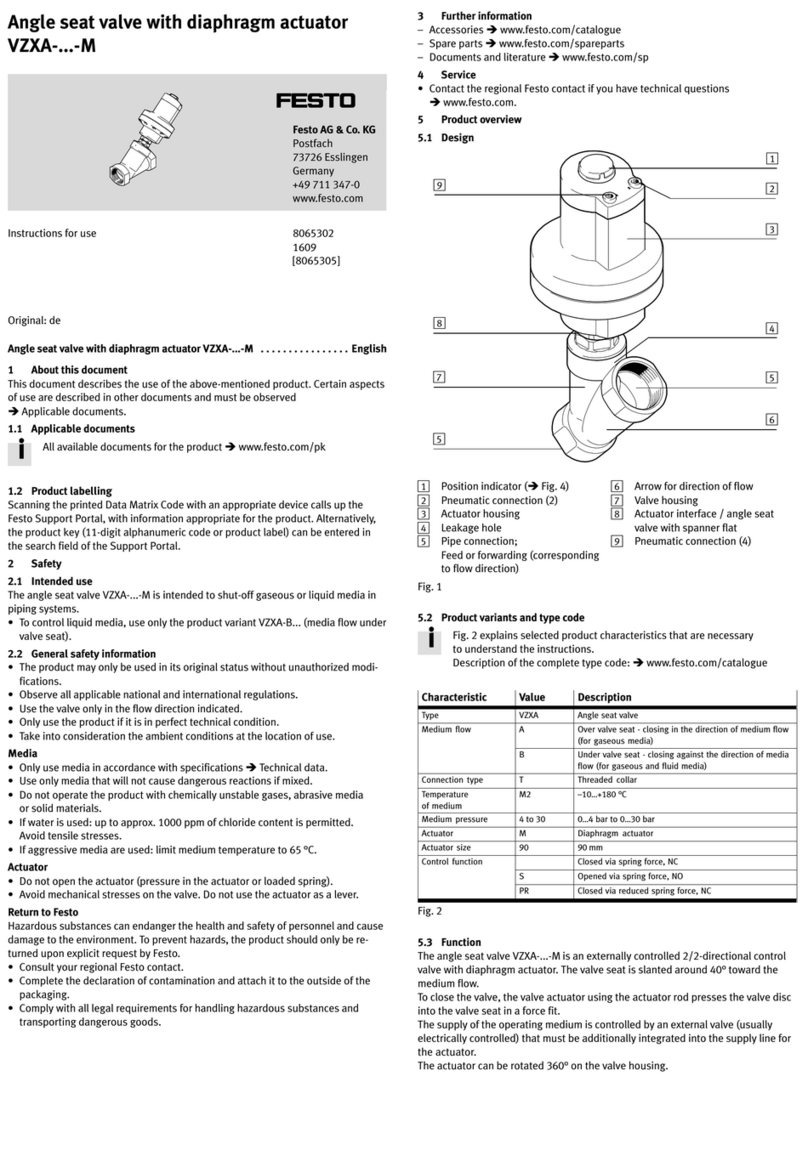

3 Ports and displays

TP2

1) Additional information è7

2) Accessories with two I-Port interfaces required to connect two

products, e.g. the decentralised electrical connection box CAPC

èwww.festo.com/catalogue

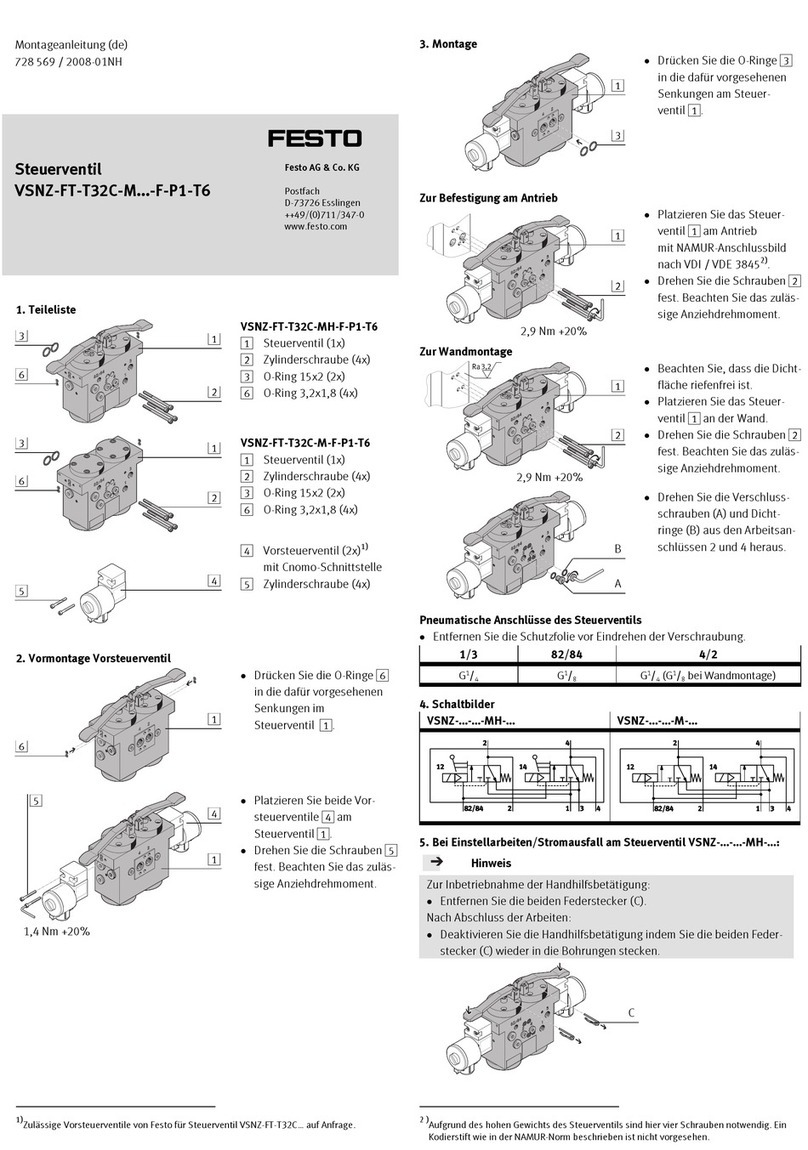

4 Mounting, dismantling, installation

Warning................................

Uncontrolled movement of the actuators, loose tubing,

undefined switching statuses of the electronics

Injury caused by moving parts, damage to machine and to system

Before mounting and installation work:

Switch off the power supply.

Switch off compressed air supply.

Vent the pneumatics.

4.1 Mounting the bus node

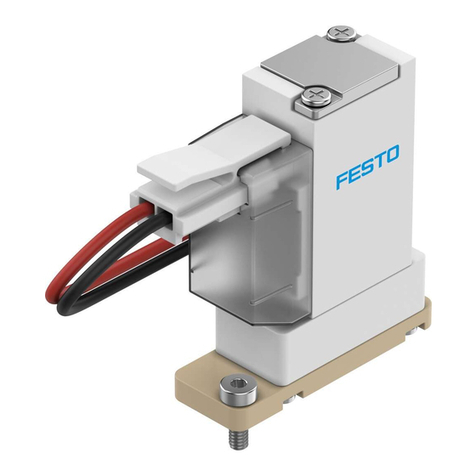

To mount the bus node, a product with I-Port interface is

required (“I-Port Device”), e.g. a valve terminal with I-Port

interface or the decentralised electrical connection box

CAPC.

Note...................................

Mounting of the bus node on the decentralised electric

al connection box èCAPC assembly instructions

1.Check seal and sealing surfaces of the bus node and the

product with the I-Port interface. Replace damaged

parts.

2.Push the bus node onto the product carefully and

without tilting and press up to the stop.

3.Gently tighten down the self-tapping screws, using

existing threads.

4.Tighten the screws. Tightening torque: 0.7 Nm ± 10 %.

4.2 Dismantling the bus node

1.Unscrew the screws.

2.Pull the bus node off without tilting it.

4.3 Connecting the power supply

Warning................................

Electric voltage

Injury caused by electric shock, damage to machine

and to system

For the electrical power supply, use only PELV circuits

in accordance with IEC60204-1/EN60204-1

(Protective Extra-Low Voltage, PELV).

Observe the general requirements IEC60204-1/

EN60204-1 of the PELV power circuits.

Use only voltage sources that ensure a reliable elec

tric separation from the mains network in accordance

with IEC60204-1/EN60204-1.

Always connect all circuits for operating and load

voltage supplies UEL/SEN and UVAL/OUT.

Fuse protection

The bus node supplies operating and load voltage to the

connected products via the I-Port interfaces X1 and X2.

Secure operating voltage UEL/SEN and load voltage

UVAL/OUT separately.

Take due account of the current consumption of con

nected products during design and protection of the

power supply.

Observe power rating of the power supply (no bus

node-internal overload protection for the connected

products) è11.

Ensure correct polarity (no bus node-internal reverse

polarity protection for the connected products).

Potential equalisation (earthing measures)

Connect the functional earth (FE) connections of the

products connected via X1 and X2 to the earth potential

with a short conductor with the greatest possible cross

section (4 mm2Cu).

4.4 Check the power supply

Note...................................

Functional testing

– The PS LED lights up when operating voltage is ap

plied (within permitted range).

–TheLEDX1 or X2 lights up green if a product with I-Port

interface is connected correctly (è7).

4.5 Connecting to the network

Installation guidelines

Warning................................

Electric voltage

Injury caused by electric shock, damage to machine

and to system

For the electrical power supply to all network parti

cipants and other network components

(e.g.switches and routers), use only PELV circuits

IEC60204-1/EN60204-1.

Note...................................

Data transmission errors

Malfunction

If installation has not been carried out correctly and

high transmission rates are used, data transmission

errors may occur, e.g. as a result of signal reflections

and attenuations.

Connect screening to all network cables

Wherever possible, only ground screening once (star-

shaped) to prevent ground loops

Observe installation guidelines of the EtherNet/IP

user organisation (ODVA): èwww.odva.org

èEtherNet/IP installation guidelines

Observe port and cable specifications:

èEtherNet/IP installation guidelines

èDocumentation on the control system

è3.1, tableof network connections

èTableof line specifications

Note...................................

Unauthorised access to the product can cause damage

or malfunctions.

When connecting the product to a network:

Protect the network from unauthorised access.

Measures for protecting the network include:

– Firewall

– Intrusion Prevention System (IPS)

– Network segmentation

– Virtual LAN (VLAN)

– Virtual Private Network (VPN)

– Security at a physical access level (port security).

Further information:

èGuidelines and standards for security in information

technology, e.g. IEC 62443, ISO/IEC 27001.

An access password protects only against accidental

changes.

Use of switches and routers

With use of the EtherNet/IP function “QuickConnect”:

Use only switches and routers that support

“QuickConnect”.

Use only patch cable.

Use of crossover cables

When using patch cables and crossover cables in the

same network:

Ensure that the crossover detection “Auto-MDI/MDI-X”

is activated in the control system

èDeactivate EtherNet/IP function “QuickConnect”

è5.8.

Cable specification

Cable Ethernet twisted pair cable, shielded

(Shielded Twisted Pair, STP)

Transmission class

(Link Class)

Category 5

Cable diameter1) 6 ... 8 mm

Wire cross section 0.14 ... 0.75 mm2; 22 AWG required for max.

connection length between network parti

cipants (End-to-end-Link)

Connection length2) Max. 100 m End-to-end-Link

1) When using plug NECUMSD12G4C2ET

2) Corresponding to the specification for EtherNet/IP networks

(EtherNet/I P installation guideline) èwww.odva.org

Strain relief

When mounting on a moving part of a machine:

Provide the network cable with strain relief.

4.6 Ensuring the degree of protection

Note...................................

Short circuit

Malfunction or damage to the electronics

Use connection technology (interconnecting cables,

push-in connectors, adapters) with the required

degree of protection, e.g. plug connector

NECU-M-S-D12G4-C2-ET.

Use cover caps to seal unused connections, e.g. cover

cap ISK-M12 èAccessories

Mount cover of the DIL switches: Check seal, place

cover and push it down, tighten screws. Tightening

torque: 0.4 Nm ± 20 %.

Do not remove sealing plug from underside of bus

node.

Only when mounting the bus node on the decentral

ised electrical connection box CAPC: Replace sealing

plug on underside of the bus node èAssembly

instructions CAPC.

5 Commissioning, configuration and parameterisation

Commissioning, configuration and parameterisation of

the bus node depends on the higher-order control sys

tem. The basic approach and required configuration data

are explained in the following sections.

Warning................................

Uncontrolled movement of the actuators, loose tubing,

undefined switching statuses of the electronics

Injury caused by moving parts, damage to machine and to system

Before commissioning, ensure that the connected

products do not perform any uncontrolled move

ments.

Observe commissioning notices in the control system

documentation.

No automatic checking of configuration and parame

terisation: The bus node and the connected products

also go into operation if configuration is incorrect.

5.1 Switch on the power supply

If the control system and network participants have sep

arate voltage supplies, the following sequence is recom

mended for switch-on:

1.Switch on the power supply to all network participants.

2.Switch on power supply to control system.

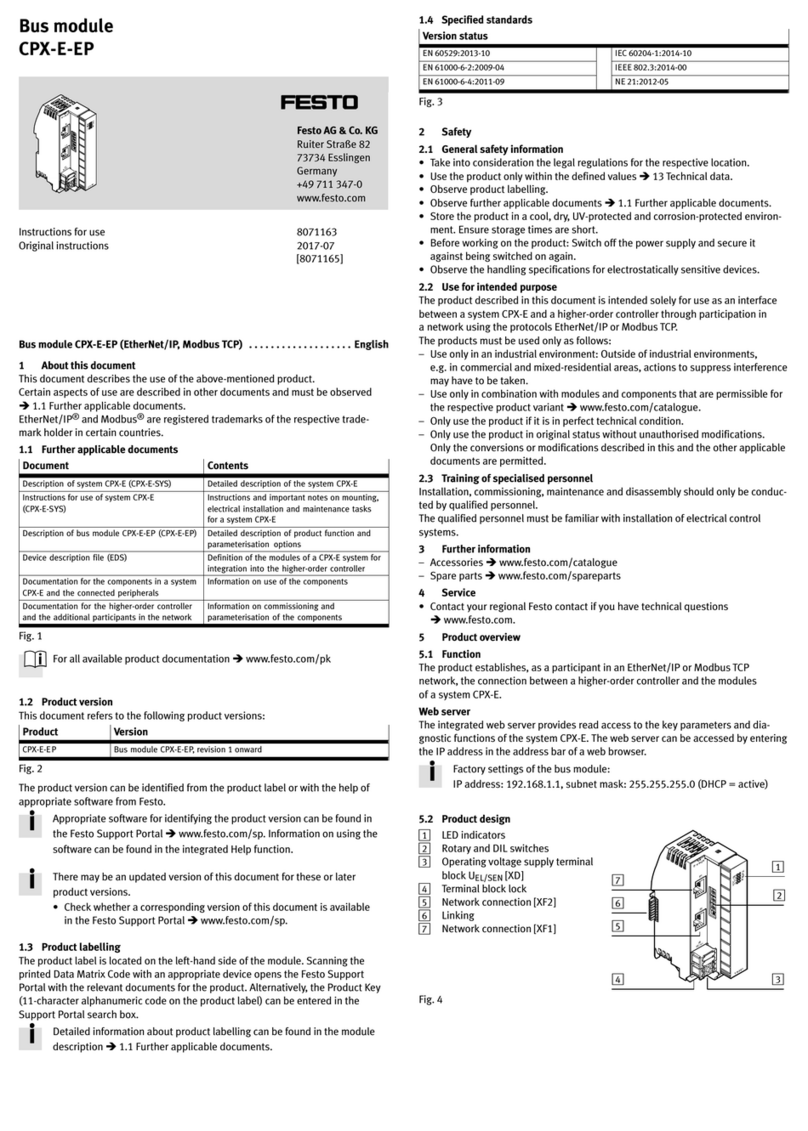

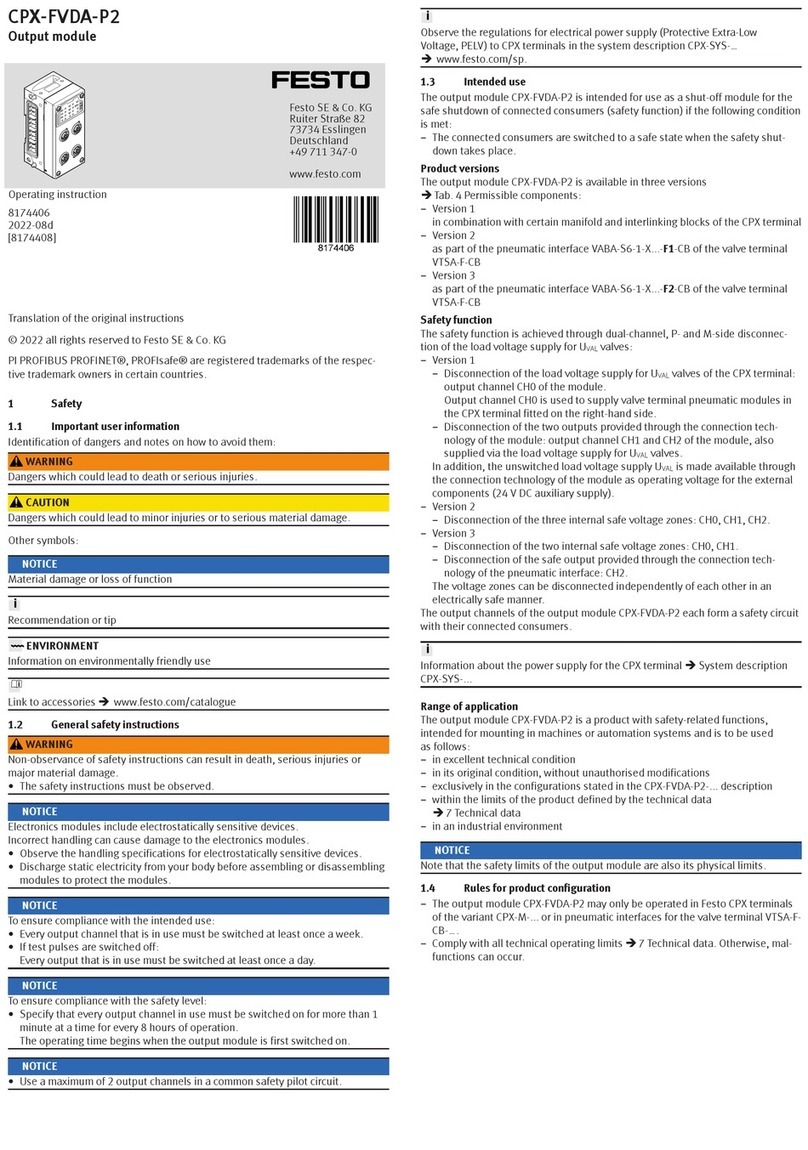

5.2 Setting the DIL switch

1.Setting IP address è5.3.

2.Perform additional settings èTable, item 3...5.

13452

Function

ON OFF

DIL switch 1:

11 ... 6: Host ID of the IP address, bit 0 ... 5 2)

DIL switch 2:

11 ... 2: Host ID of the IP address bit 6 and 7 2)

23: Reserved

34: Network protocol ModbusTCP EtherNet/I P3)

45: Status bytes

è 5.5 èTable

“Connection Para

meters”

Status informa

tion in the input

image

No status inform

ation in the input

image3)

56: Behaviour in case

of communication

errors and for

control in the

Idle-Mode

All outputs re

tain their last

switching status

All outputs are

reset3)

1) Switch setting “ON” = ON, switch is to the left or on top

switch setting “OFF” = OFF, switch is to the right or underneath

2) Binary coding in ascending order from left to right 20, 21, 22, …

3) Factory setting

5.3 Setting IP address

èDocumentation of the control system

Note...................................

Observe the basic addressing rules for the allocation

of the IP address, e.g. with respect to the use of

private or public address ranges.

Check that the IP address can be used in the automa

tion network.

Ensure that there is no duplication of IP addresses in

use.

Use DIL switches 1for setting the addressing type or

for setting the host ID of the bus node.

The change of IP addressing in the bus node re

quires a corresponding update in the higher-or

der control system.

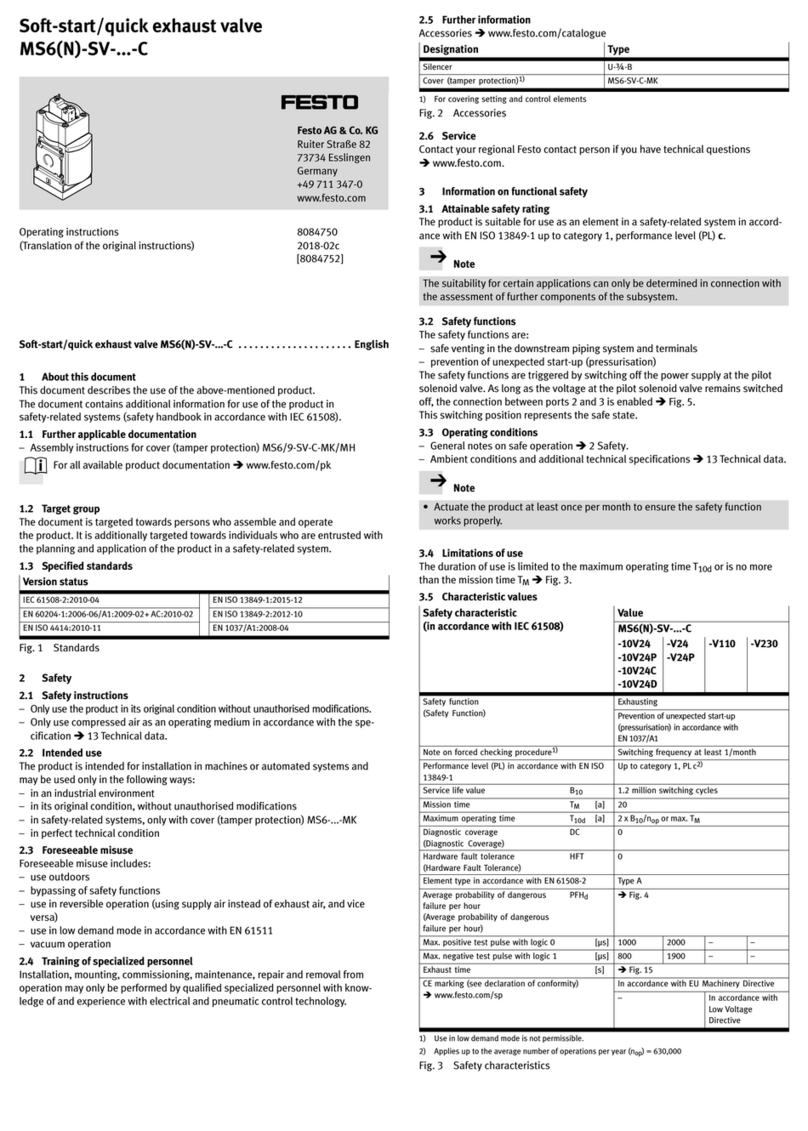

Examples

Host ID = 05 Host ID = 38

1234 56 1 2 1 2

1234 56

20+ 22= 1 + 4 = 5

Set IP address:

192.168.1.005

21+ 22+ 25= 2 + 4 + 32 = 38

Set IP address:

192.168.1.038

Dynamic addressing

1.Make sure there is a DHCP server (e.g. BOOTP DHCP

server from Rockwell Automation) in the network.

2.Set all switch elements for address setting DIL1 (1...6)

and DIL2 (1...2) to “OFF”.

3.With Festo Field Device Tool (FFT) or EtherNet/IP

Object, activate the “DHCP” option.

4.Switch bus node off and back on.

Saved addressing

1.Set all switch elements for address setting DIL1 (1...6)

and DIL2 (1...2) to “OFF”.

2.Set the IP address with the Festo Field Device Tool (FFT)

or EtherNet/IP Object.

3.Switch bus node off and back on.

Static addressing

1.Set the first three octets of the IP address with the

Festo Field Device Tool (FFT) or EtherNet/IP Object.

2.With all switch elements for address setting DIL1(1...6)

and DIL2(1...2), set the fourth octet (Host-ID) of the IP

address.

3.Switch bus node off and back on.