I-2 Safety Instructions

2. Safetysymbols

(continueoy WARNING: Risk of explosion or fire. Fire, open lights and

smoking prohibited. Failure to observe may result in

personal injury or death.

n

0WARNING: System or material pressurized. Release

pressure. Interrupt compressed air, set motor switch to “0”

and release hot melt material pressure by actuating the

extrusion guns. Failure to observe may result in serious

burns.

3. Intended use The unit is designed and intended to be used only for the purpose

described in Section 2 “Equipment Familiarization”. Uses not in

accordance with the Section are considered unintended uses and not in

accordance with governing regulations.

The following actions of the owner or operator of the unit are some but

not all examples of unintended use which would permit Nordson to

claim it is not responsible for personal injury or property damage arising

from such unintended use:

l unapproved modifications or changes to the unit

l failure to comply with the Safety Instructions

l failure to comply with instructions concerning installation, use,

operation, maintenance, or repair, or when these tasks are carried

out by unqualified personnel

l use of inappropriate or incompatible foreign materials or auxiliary

equipment

l failure to observe workplace safety rules or regulations issued by

government authorities or safety councils

NOTE: Operators or maintenance workers are regarded as being

“qualified personnel” when they have gained, through training and

experience, an understanding of the manner in which the unit is to be

operated, serviced and repaired, and based on safe workplace

practices are familiar with relevant regulations.

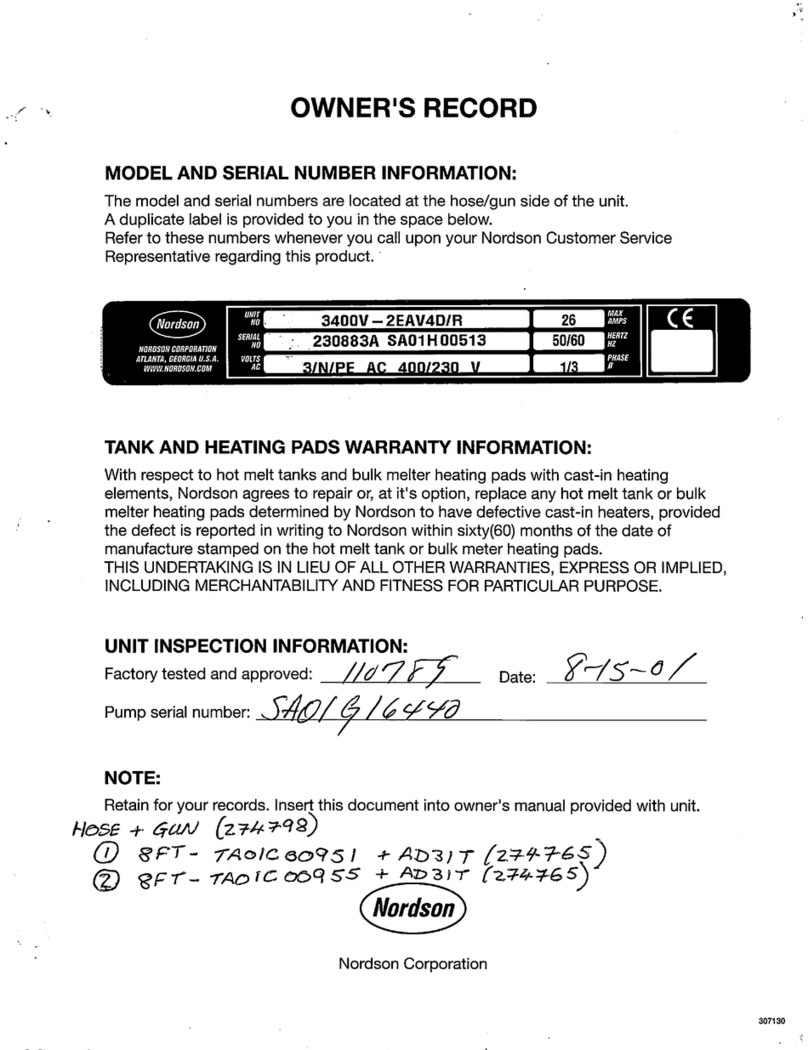

4. Installationand electrical

connections ” l All electrical, pneumatic, gas, and hydraulic connections and

installations of heated hoses and hot melt applicators may only be

carried out by qualified personnel. Be sure to observe installation

instructions for components and accessories.

Equipment must be properly grounded and fused according to its

rated current consumption (see ID plate).

Cables which run outside the unit must regularly be checked for

wear and tear or damage.

The conductors of cables connecting the unit to the main electrical

supply must have adequate diameters according to the rated current

consumption.

PM 106 701A

41-2300SP - Issued 1194 0 Nordson Corporation 1994

All Rights Resented