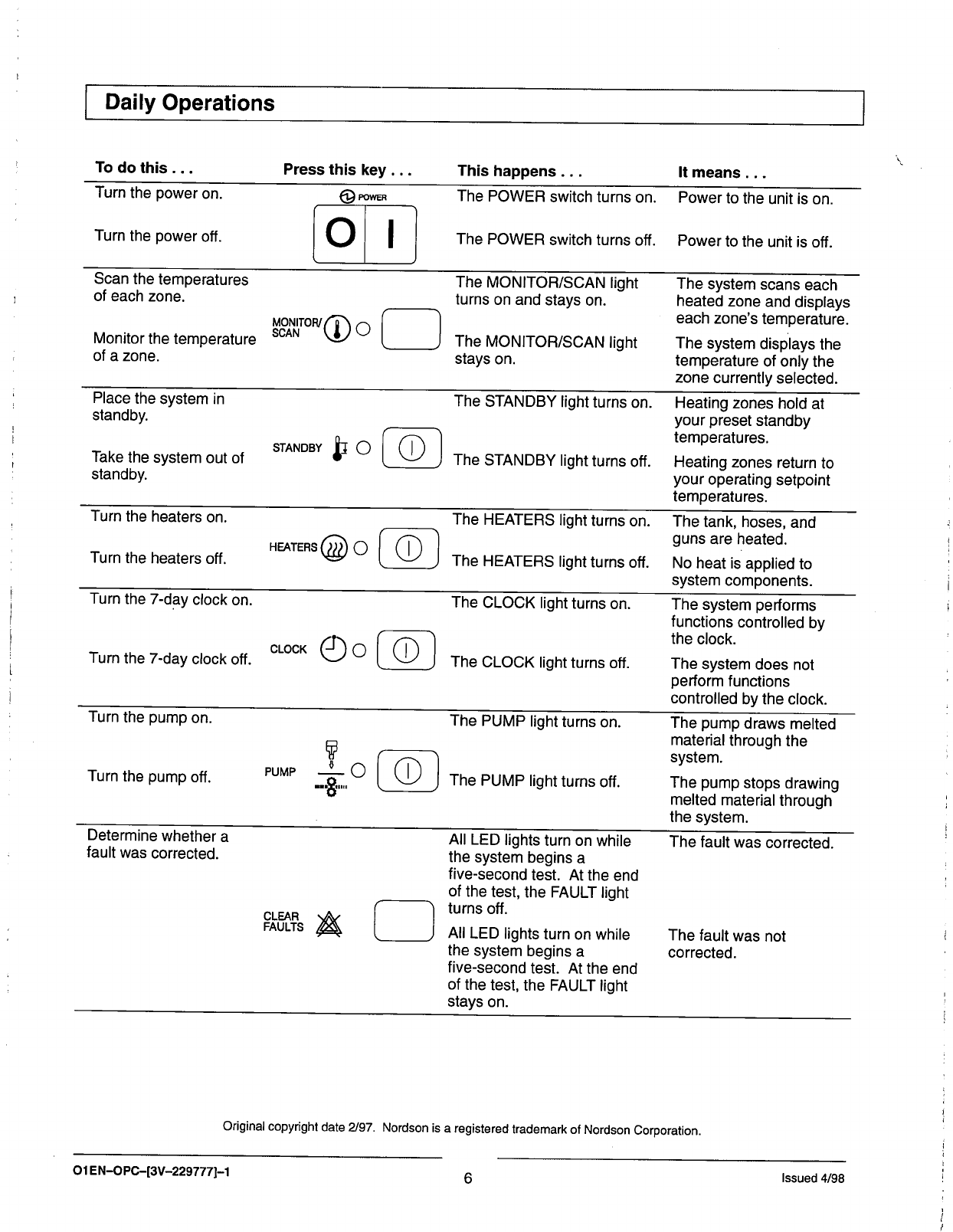

Nordson CorPoration

OPERATOR'S CARD

P/N 229 777c

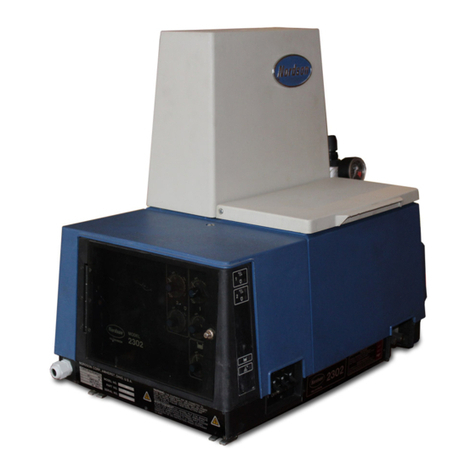

Series 31OO Vlg4OOYl3500 Vl3700V

Hot tMelt tVlaterial APPlicator

with Piston Pump, standard Filter, standard control

IMPORTANT

Give this coPY

to the oPerator

Please Note

The operator's card contains only information

necessary for daily operation and maintenance'

Foiotreiintormation, reler to the product manual

A copy of this operator's card and an order form for

anotirer operator's card are included in the

introduction part of the operating manual'

AWARNING: Allow only qualified personnelto

perform the following tasks. Observe and

iollow the safety instructions in this document

and all other related documentation'

Always follow the instructions given in the

operator's card and operating manual'

Always follow instructions in the material supplier's

tvtateiiat Safety Data Sheet (MSDS) or material

information sheet.

Even at recommended operating temperatures'

hot melt material may release vapors' Exceeding

prescribed processing temperatures for long

periods of time can result in dangerous

decomposition by-products. Flemove vapors

by drawing them off with an exhaust system'

a

a

a

Safety SYmbols

The following symbols warn against dangers or

oossible sou-rces of danger. Become familiar with

inemt faiture to heed a warning symbol can lead to

personal injury and/or damage to the unit or other

equipment.

A

A

WARNING: Failure to observe can result in

equipment damage, personal injury, or death'

WARNING: Risk of electrical shock' Failure to

obserue can result in personal injury or death'

WARNING: Disconnect equipment from line

voltirge. Failure to observe can result in

personal injury or death.

WARNING: Hot! Risk of burns. Wear

heat-protective clothi n g, saf ety gog gles, and/or

heat-protective gloves depending on the

symbol or symbols shown. Failure to observe

can result in personal injury or death'

WARNING: Pressurized system or material

Release pressure. Failure to observe can

result in serious burns.

@

@

@

A

1

lssued 4/98 o 1 E N-O P C-[3V -229774-1