Overview

A 2-2

E2000 Nordson Corporation

All rights reserved

41-3000

Issued 11/00

A2EN-02-[3-OVER]–2

The melter has three basic modes of operation: startup, operating, and

standby. Each heated component (each hose, each gun, and the tank) is

referred to as a zone.

There are two types of startup mode: cold startup and warm startup.

Cold Startup

When the melter is turned on, the control system checks the temperature

of all zones. If the controller detects that the temperature of any zone

that is turned on is more than 19 °C (35 °F) below its setpoint

temperature, the melter will perform a cold startup. First the tank and

hoses begin to heat. When the temperature of the tank and the hoses is

within 19 °C (35 °F) of the setpoint temperature, the guns begin to heat.

When all zones are within 3 °C(5°F) of their setpoint temperatures, a

time delay begins. The time delay provides additional time for the

adhesive in the tank to melt. The default time delay setting for gear

pump melters is 46 minutes. At the end of the time delay, the green

SYSTEM READY light turns on to indicate that the system is ready for

operation and the parent machine interlock (PMI) (if used) is enabled.

Warm Startup

When the melter is turned on, the control system checks the temperature

of all zones. If the temperature of all zones that are turned on is within

19 °C (35 °F) of the setpoint temperature, the melter performs a warm

startup. Steady power is applied to each zone until the tank, hoses, and

guns are within 3 °C (5 °F) of their setpoint temperatures. When this

occurs, the green SYSTEM READY light turns on to indicate that the

system is ready for operation and the PMI (if used) is enabled. There is

no time delay during a warm startup.

When a gun is triggered, the pump draws in the melted adhesive and

pushes it through a manifold, filter, and hose to a dispensing gun. The

gun applies the adhesive to the product or package surface.

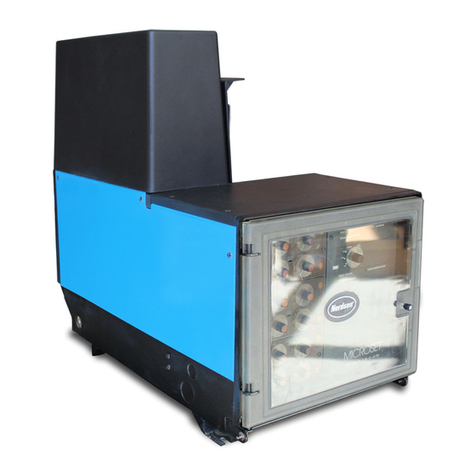

Figure A 2-2 shows the path that melted adhesive follows as it flows

through the system.

2. Functional Operation

Startup Mode

Operating Mode