Tank and Manifold

B 3-8

E2000 Nordson Corporation

All rights reserved

41-3000

Issued 9/00

B3EN-03-[3-TANK]-3

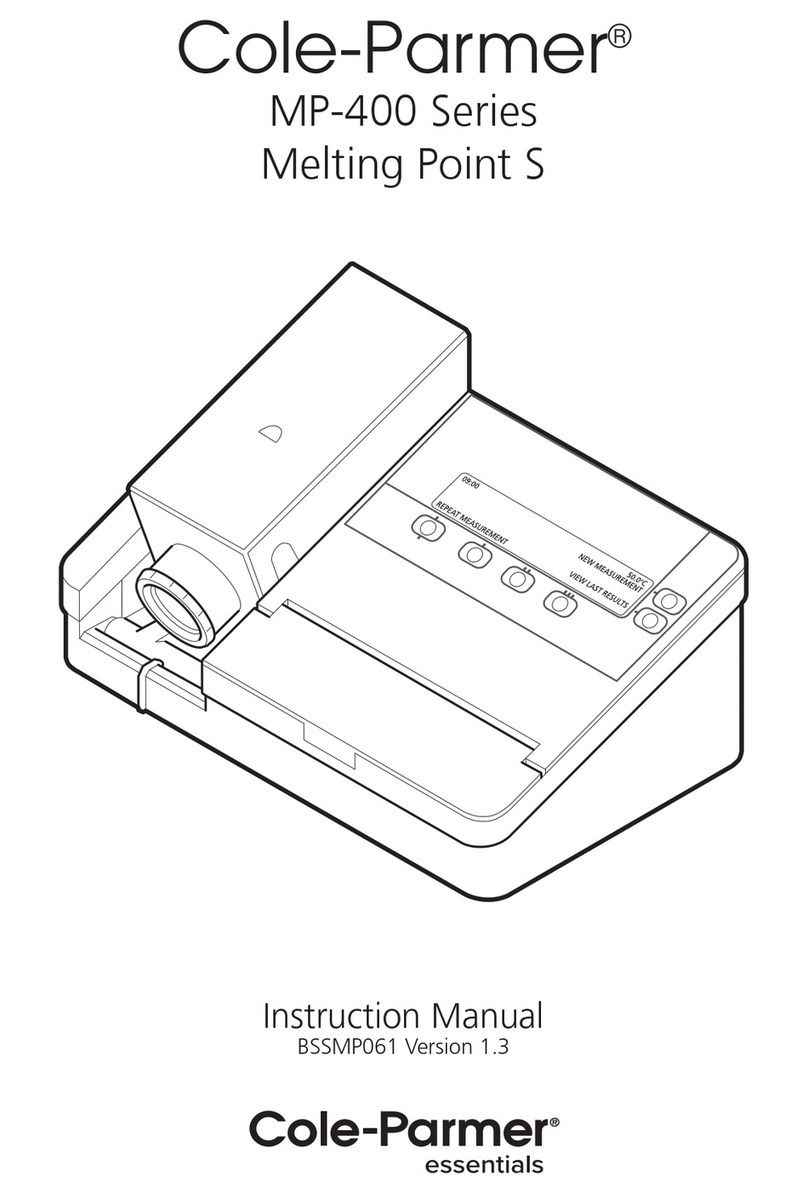

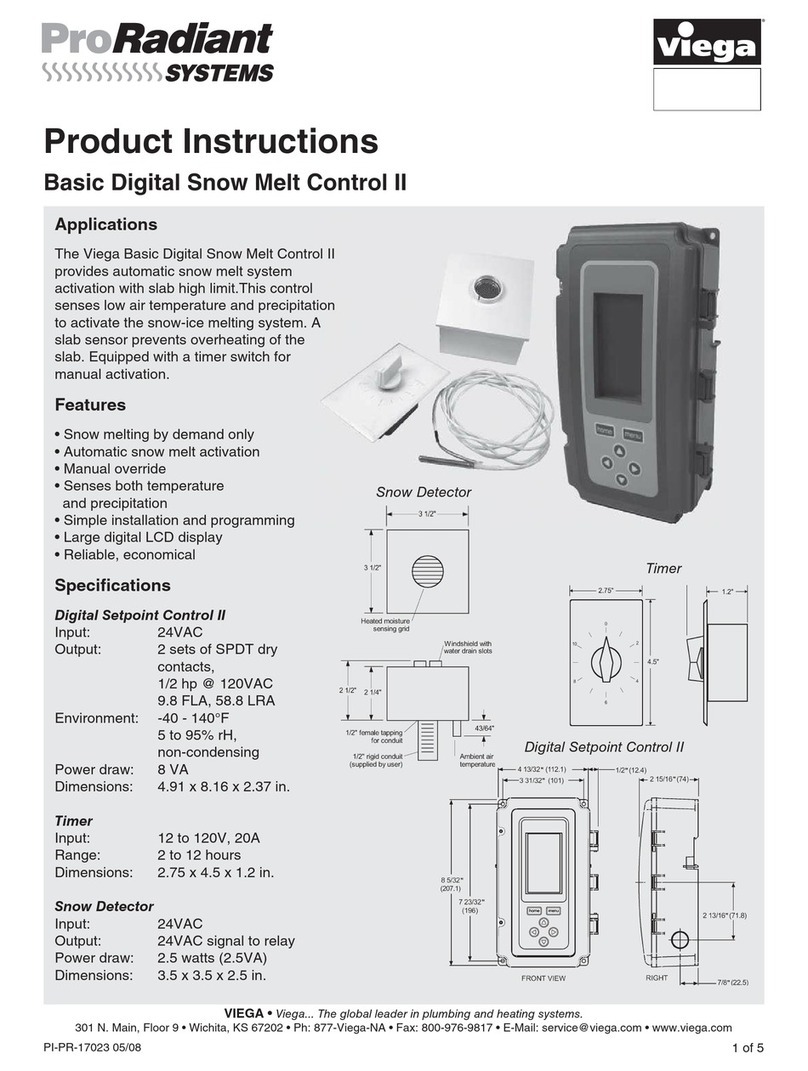

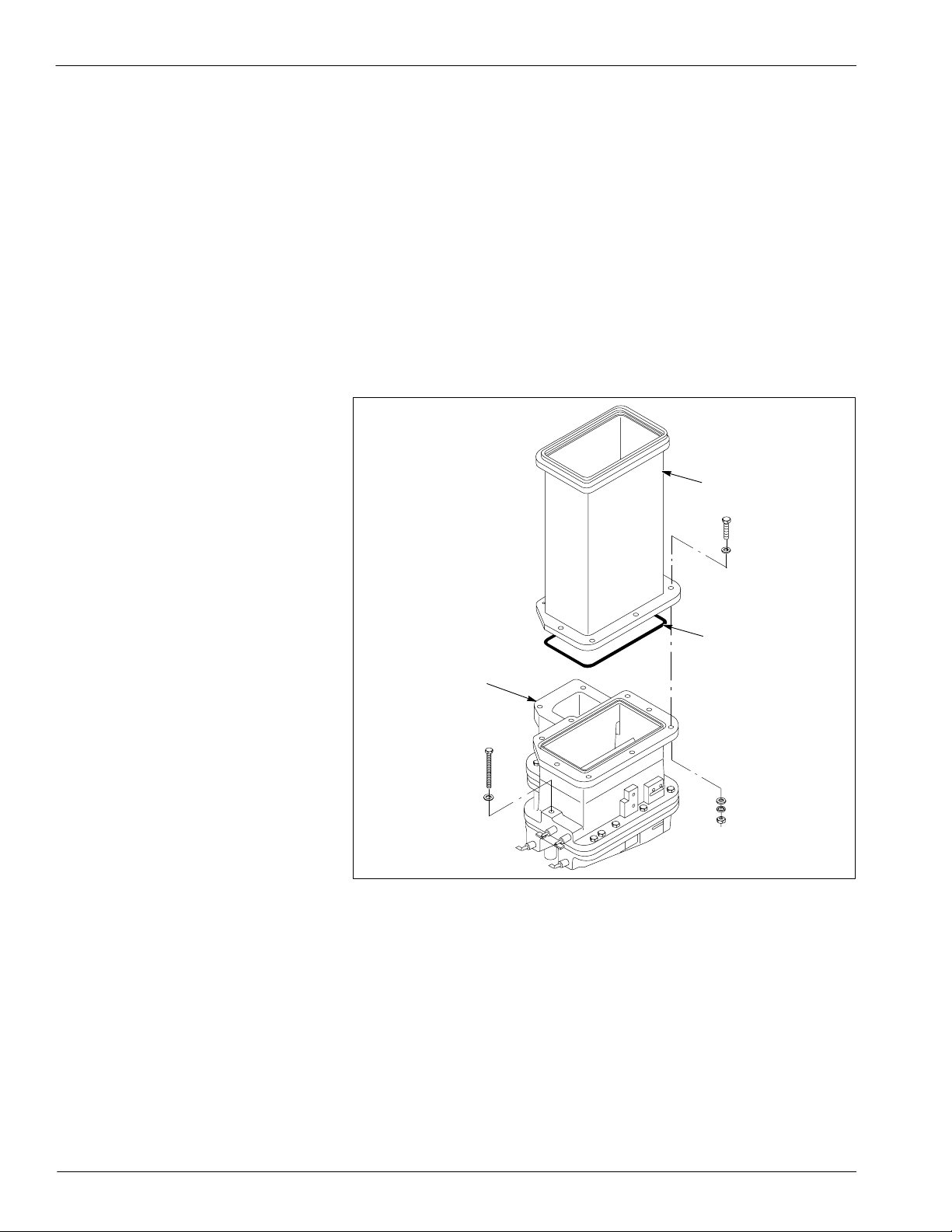

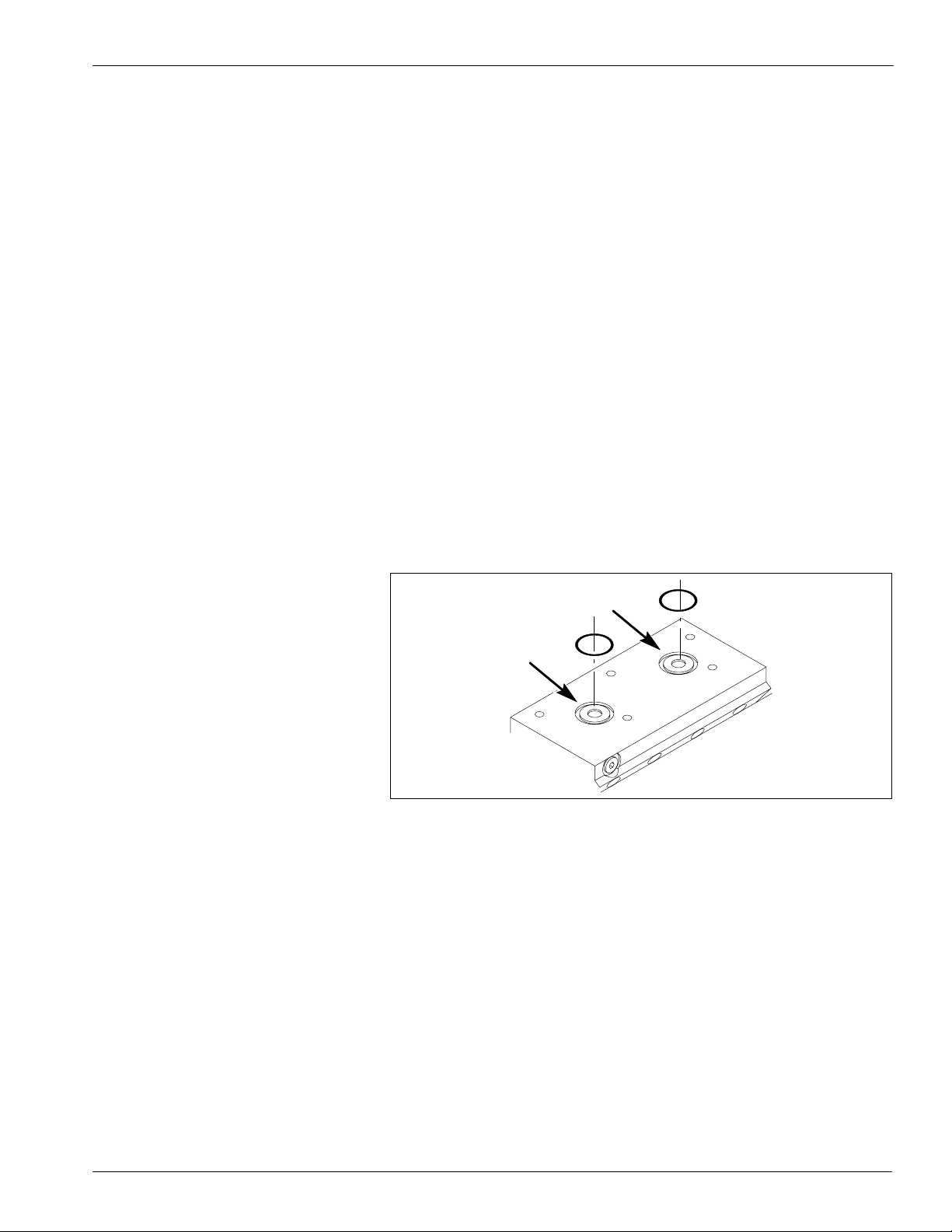

4. Insert the manifold washers and screws in the bottom of the manifold

and tighten them finger tight only. Then tighten the screws in the

sequence shown in Figure B 3-6. Tighten the screws to

5.4–6.8 NSm(4–5 ft-lb).

4130604A

1

2

3

4

5

Fig. B 3-6 Correct Sequence for Tightening Manifold Screws

5. Turn the reservoir and manifold over so that the reservoir’s open side

is up and wrap the insulation around the reservoir and manifold. Use

high-temperature duct tape to secure the insulation.

6. Reconnect the heater wires to the reservoir heater connections.

7. Hold the spacers in place and attach the reservoir and manifold to the

base of the melter with the screws and washers removed earlier. It

may be necessary to tilt the melter to gain access to the bottom of the

base. Tighten the screws to 10.9–13.6 NSm (8–10 ft-lb).

NOTE: Be sure you do not pinch the heater wires when you are

securing the reservoir and manifold to the base.

NOTE: To ease assembly, you can cut the heads off of four M8

screws that are longer than the spacers (do not use the screws

supplied with the service kit). Loosely thread the cut screws into the

tapped holes in the bottom of the manifold. Slip the spacers over the

screws. This will keep the spacers in line until you are ready to install

the supplied screws. When you are ready to install the supplied

screws, remove the cut screws. Ask an assistant to help you tilt the

melter and support it while you replace the screws and washers.

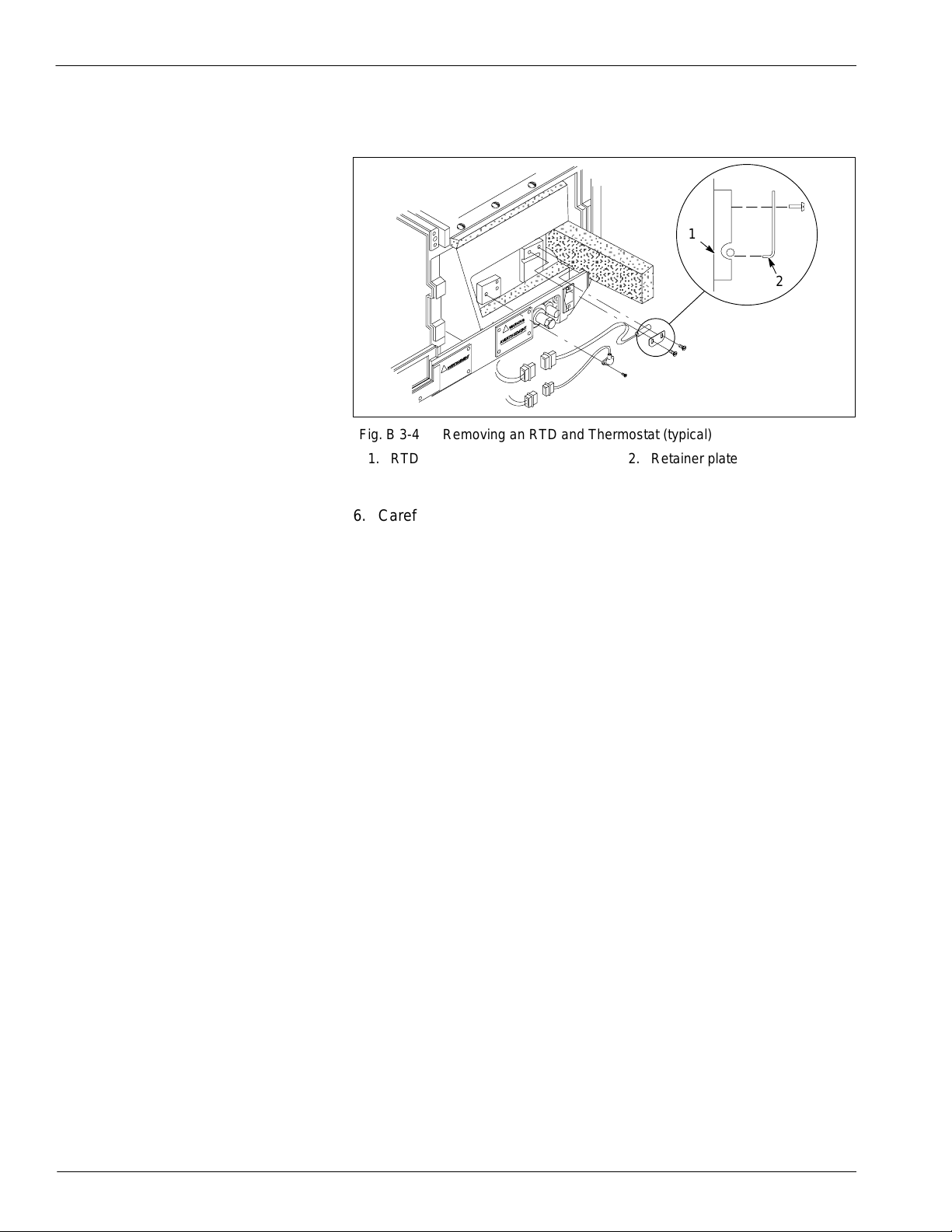

8. Apply thermal compound to the RTD and thermostat and install them

on the side of the reservoir. Make sure the RTD retainer plate is

installed as shown in Figure B 3-4.

9. Reconnect the ground wire (if present) to the reservoir.

10. If the melter was attached to a support platform, anchor it to the

platform now.

Reassembling the Reservoir

and Manifold (contd.)