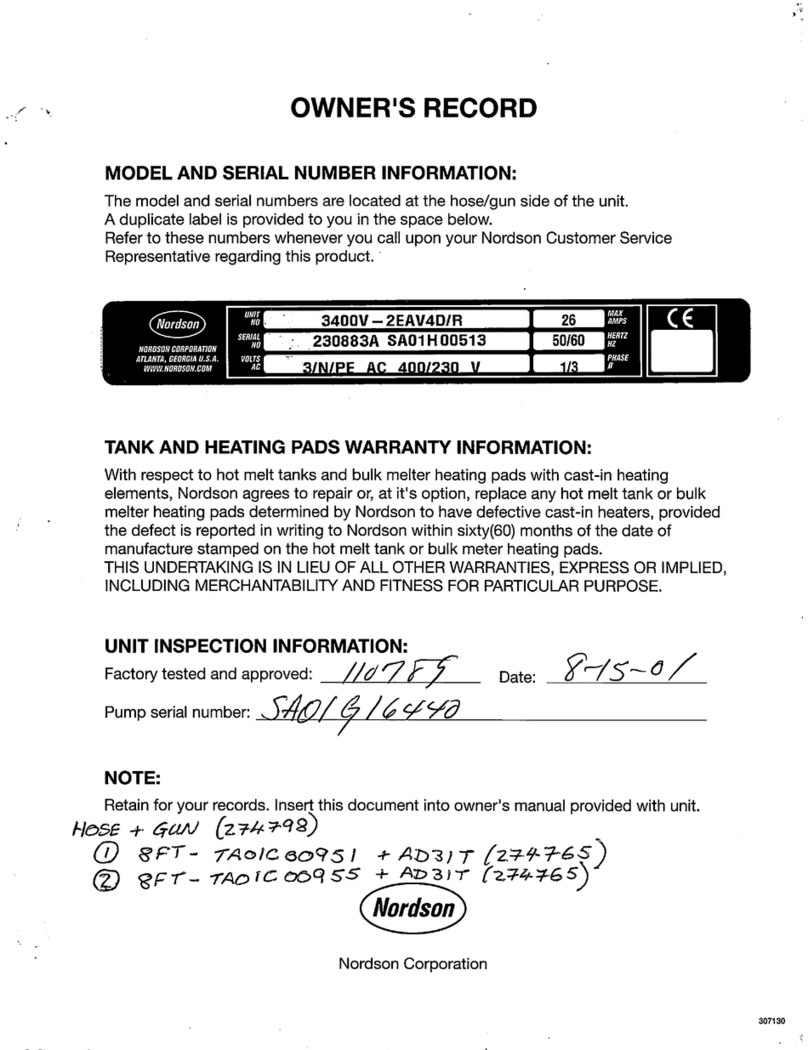

Nordson 3400 User manual

Other Nordson Melting Machine manuals

Nordson

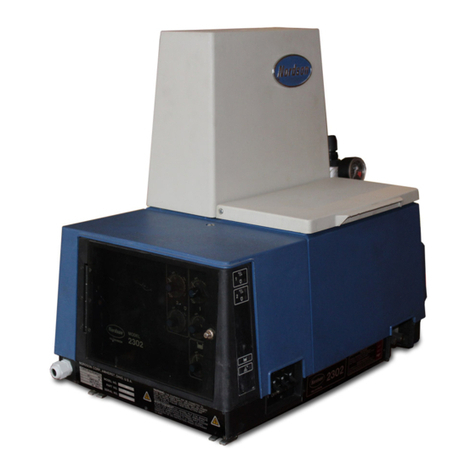

Nordson 2302 User manual

Nordson

Nordson ProBlue Flex User manual

Nordson

Nordson 3500V Series Parts list manual

Nordson

Nordson ProBlue 1028303 User manual

Nordson

Nordson 3500 Series Parts list manual

Nordson

Nordson DuraDrum User manual

Nordson

Nordson ProBlue Flex User manual

Nordson

Nordson ProBlue Flex User manual

Nordson

Nordson EP 30 User manual

Nordson

Nordson 3100 User manual

Popular Melting Machine manuals by other brands

Cole Parmer

Cole Parmer MP-400 Series instruction manual

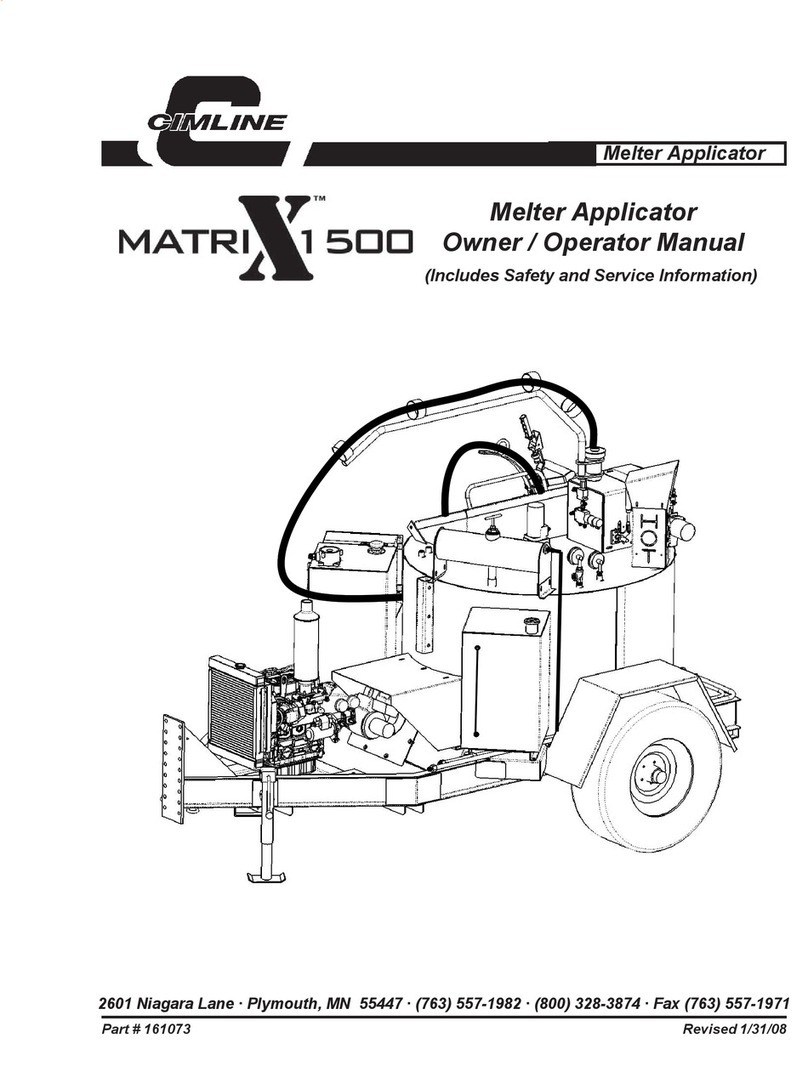

CIMLINE

CIMLINE MATRIX 1500 Owner's/operator's manual

Graco

Graco THERM-O-FLOW T7 Series instructions

VALCO MELTON

VALCO MELTON D4-L user manual

Meler

Meler MACRO 200 instruction manual

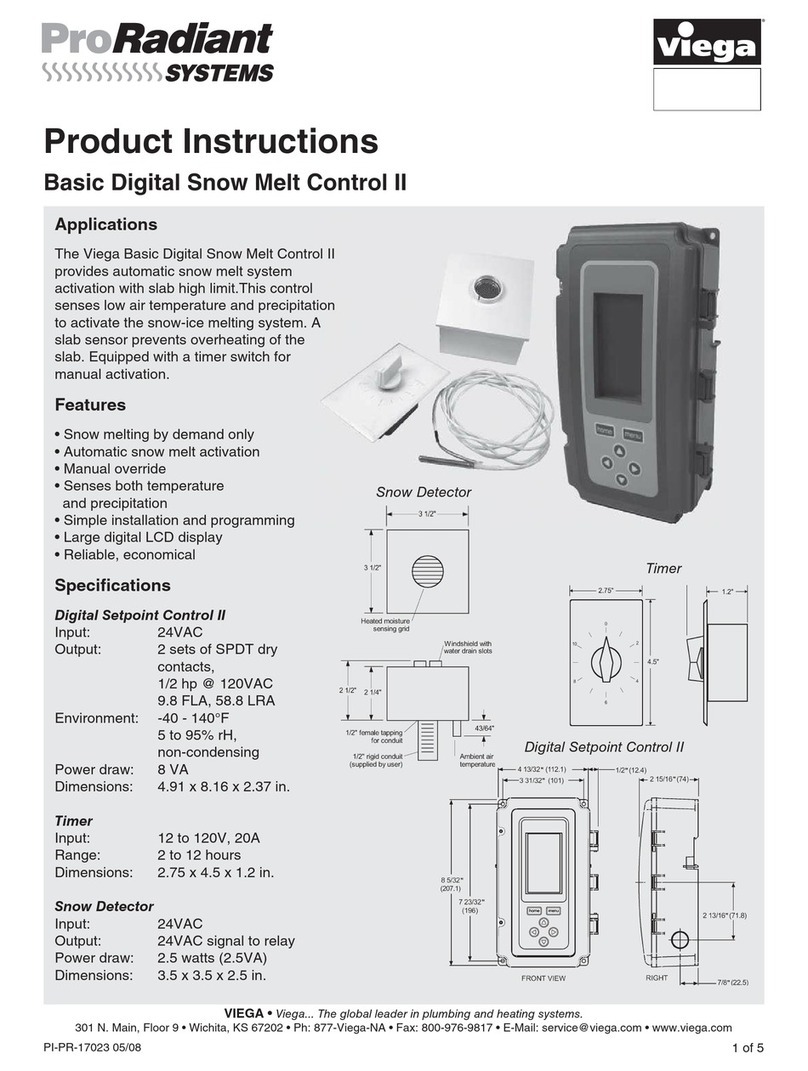

Viega

Viega ProRadiant Basic Digital Snow Melt Control... Product instructions