A951 4 532081 - RevA

Translation of the original instructions ENGLISH

CONTENTS

Declaration of incorporation for partly completed

machinery............................................. 3

1. INTRODUCTION TO THIS INSTRUCTIONS MANUAL...6

1.1 Meaning of the symbols used ......................... 6

2. SAFETY RECOMMENDATIONS ........................8

2.1 Installer safety ....................................... 8

2.2 Transport and storage ................................ 8

2.3 Unpacking and handling.............................. 9

2.4 Waste disposal ....................................... 9

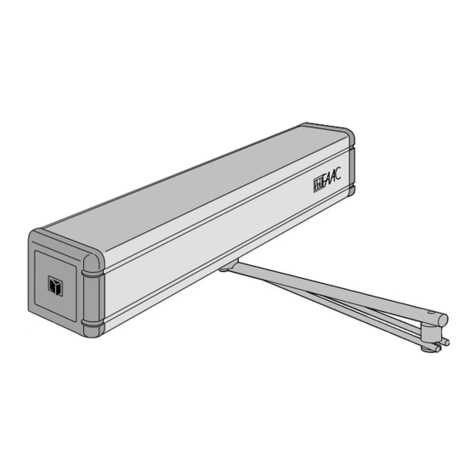

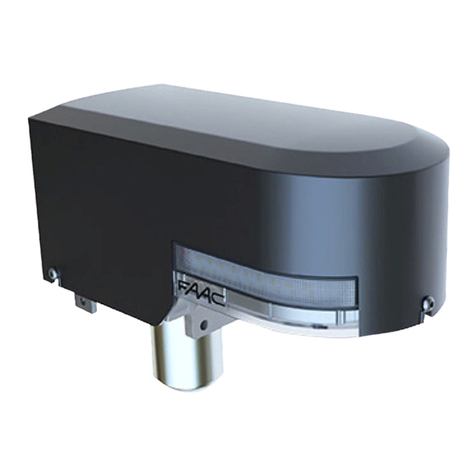

3. A951 .................................................10

3.1 Intended use........................................ 10

3.2 Application limits ................................... 10

3.3 Unauthorised use ................................... 10

3.4 Emergency Use...................................... 10

3.5 Manual operation ................................... 10

3.6 Product identification................................ 11

3.7 Technical characteristics ............................. 11

3.8 Component identification............................ 14

4. INSTALLATION REQUIREMENTS......................15

4.1 Mechanical requirements ............................ 15

4.2 Electrical system .................................... 15

4.3 Protection against door movement hazards ........... 16

4.4 Example system..................................... 16

4.5 Description of components........................... 17

4.6 Tools required ....................................... 17

5. MECHANICAL INSTALLATION.........................18

5.1 Cable inlet A951 .................................... 18

5.2 Fastening the A951.................................. 18

5.3 Sliding arm ......................................... 20

5.4 Articulated arm ..................................... 22

5.5 Connecting the transmission arm .................... 24

6. ELECTRONIC INSTALLATION..........................25

6.1 Communication Board ............................... 25

6.2 Cover............................................... 25

6.3 Connecting to the mains power supply................ 25

6.4 Connecting to the I/O board.......................... 25

6.5 I/O Board ........................................... 26

J3 - KP EVO............................................ 26

J4 - Inputs ............................................ 26

J5 - Outputs........................................... 27

6.6 Connecting safety sensors ........................... 28

Connecting XPB ON.................................... 28

Connecting the XPB SCAN.............................. 28

6.7 Connecting the lock ................................. 29

6.8 Inputs configuration (J4)............................. 30

6.9 Outputs configuration (J5) ........................... 31

7. SETUP ...............................................32

7.1 Programming the A951.............................. 32

7.2 On board programming.............................. 32

BASIC programming................................... 33

ADVANCED programming.............................. 33

7.3 Operating mode..................................... 37

7.4 Set-up.............................................. 38

7.5 Reset............................................... 38

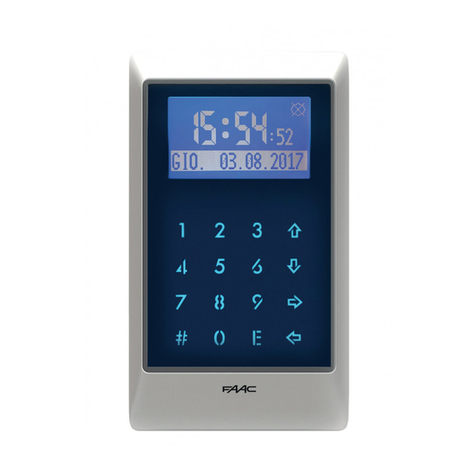

8. KP EVO ...............................................39

8.1 Installation and connections ......................... 39

8.2 Switching on and the home screen ................... 40

8.3 SELECTION menu .................................... 41

8.4 FUNCTIONS menu ................................... 42

Programming......................................... 47

Errors ................................................ 47

Warnings ............................................. 47

Cycle counter ......................................... 48

Date / Time ........................................... 48

Timer................................................. 48

Password............................................. 48

9. DIAGNOSTICS ........................................49

9.1 LEDs check.......................................... 49

I/O board LEDs ........................................ 49

Logic board LEDs ...................................... 49

9.2 Inputs and outputs status check ...................... 49

On the board.......................................... 49

On the KP EVO ........................................ 49

9.3 Automation status check............................. 50

On the board.......................................... 50

On the KP EVO ........................................ 50

9.4 Warnings ........................................... 50

On the board.......................................... 50

On the KP EVO ........................................ 50

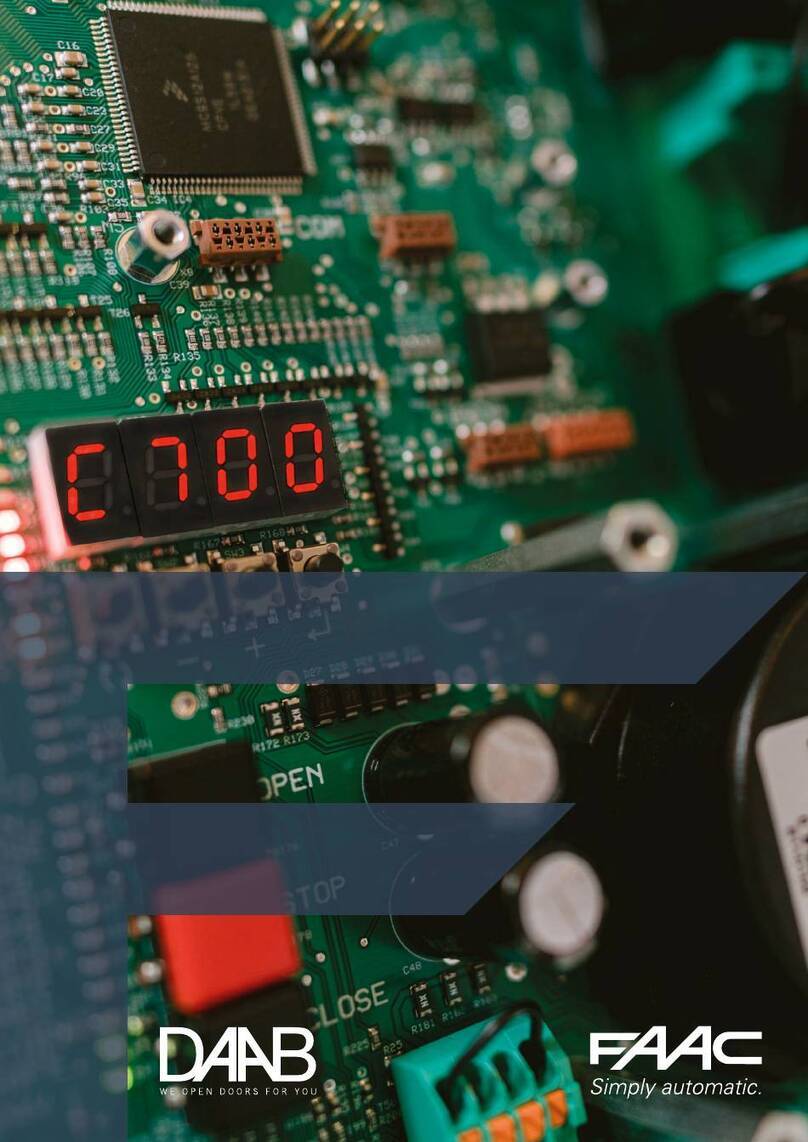

9.5 Errors............................................... 51

On the board.......................................... 51

On the KP EVO ........................................ 51

9.6 Other board data.................................... 52

9.7 Firmware versions................................... 52

On the board.......................................... 52

On the KP EVO ........................................ 52

9.8 Log Data............................................ 52