TABLE OF CONTENTS

SECTION 1 –INTRODUCTION.............................................................................................................. 4

1.1. USE AND FUNCTION............................................................................................................. 4

SECTION 2 –TECHNICAL SPECIFICATIONS...................................................................................... 5

2.1. TECHNICAL SPECIFICATIONS TABLE................................................................................. 5

2.2. ACCESSORIES FOR NF200.................................................................................................. 5

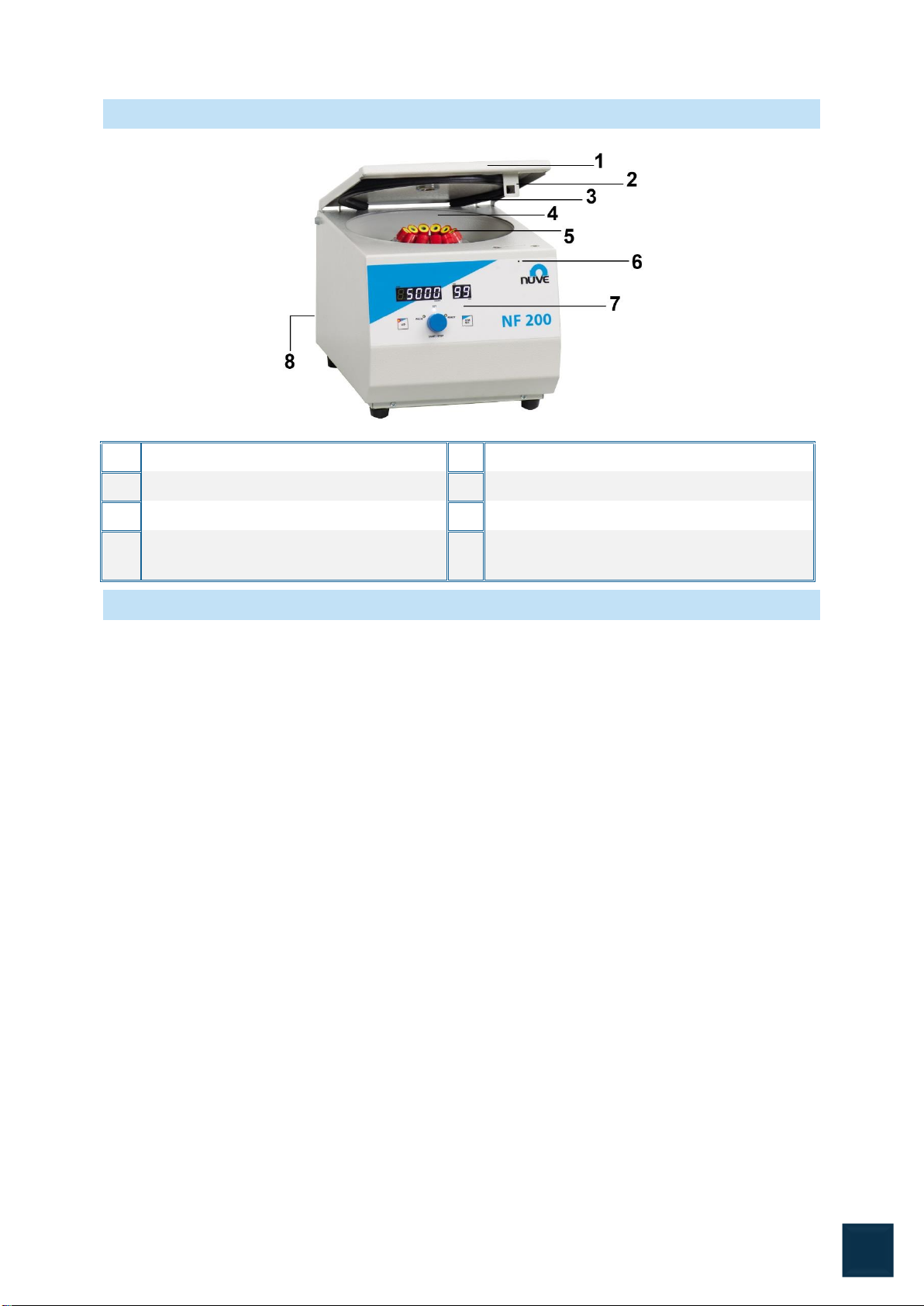

2.3. GENERAL PRESENTATION .................................................................................................. 6

2.4. RECAUTIONS AND USAGE LIMITATIONS........................................................................... 6

SECTION 3 –SYMBOLS........................................................................................................................ 7

SECTION 4 –INSTALLATION................................................................................................................ 7

4.1. LIFTING AND TRANSPORT................................................................................................... 7

4.2. UNPACKING ........................................................................................................................... 7

4.3. POSITIONING......................................................................................................................... 7

4.4. MAIN SUPPLY......................................................................................................................... 8

SECTION 5 –OPERATING UNIT........................................................................................................... 8

5.1. OPERATING............................................................................................................................ 8

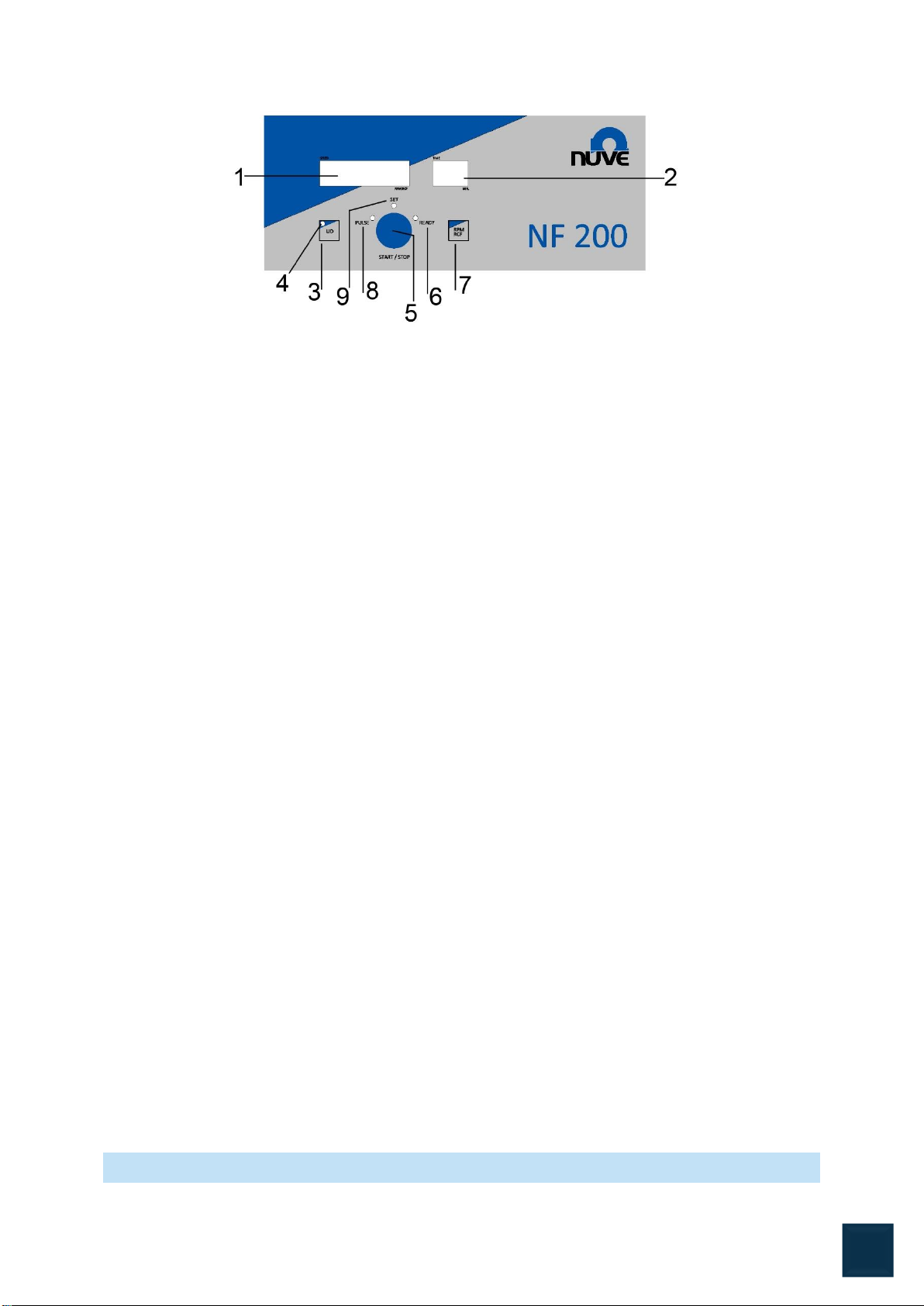

5.2. DISPLAY AND CONTROL PANEL ......................................................................................... 8

5.3. MAKING PROGRAM............................................................................................................... 9

5.3.1 PULSE MODE................................................................................................................... 10

5.4 SAFETY INTERLOCK SYSTEM........................................................................................... 11

5.5 MANUAL LID OPENING ....................................................................................................... 11

SECTION 6 –OPERATING PRINCIPLES............................................................................................ 12

6.1 PREPARATION OF THE ROTOR TO RUN.......................................................................... 12

6.2 LOADING............................................................................................................................... 12

6.3 DRIVE SYSTEM.................................................................................................................... 13

SECTION 7 –CLEANING AND PERIODIC MAINTENANCE............................................................... 13

7.1 PERIODIC MAINTENANCE.................................................................................................. 13

7.2 STERILIZATION.................................................................................................................... 13

7.3 CORROSION INFORMATION .............................................................................................. 13

7.4 CLEANING ............................................................................................................................ 14

7.5 ELECTRICITY ....................................................................................................................... 14

SECTION 8 –DISPOSAL MANAGEMENT CONCEPT........................................................................ 14

BÖLÜM 9 –TROUBLESHOOTING ...................................................................................................... 15

SECTION 10 –ELECTRICAL CIRCUIT DIAGRAMS ........................................................................... 16

SECTION 11 –WARNING LABEL........................................................................................................ 17