MB35 EN-1

Contents

1. INTRODUCTION .....................................................................................................EN-2

1.1 Safety Precautions ......................................................................................................EN-2

2. INSTALLATION ..........................................................................................................EN-4

2.1 Unpacking and Checking Equipment..............................................................................EN-4

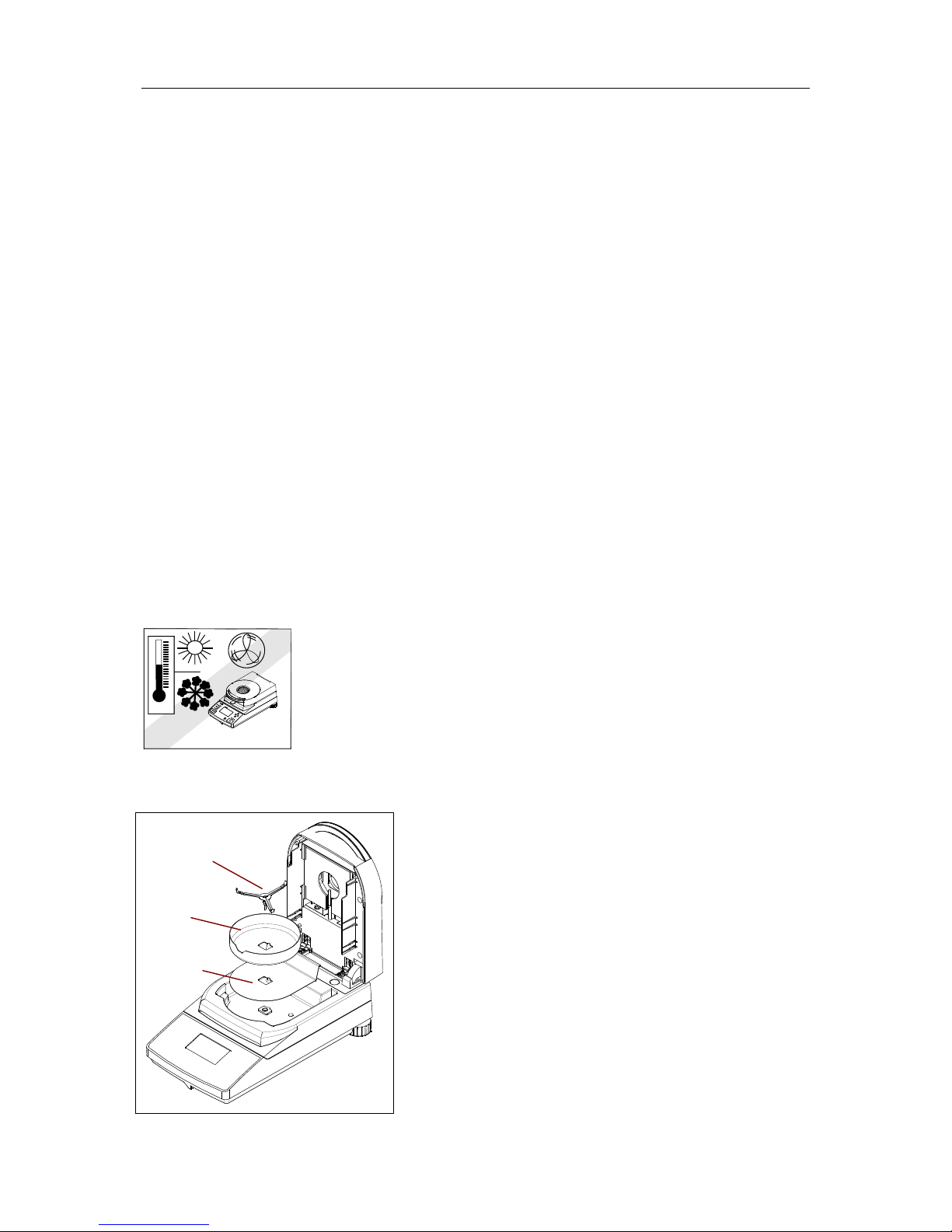

2.2 Selecting the Location..................................................................................................EN-4

2.3 Installing the Heat Shield, Draft Shield and Pan Support ...................................................EN-4

2.4 Connecting to a Power Supply ......................................................................................EN-5

2.5 Operating Controls ......................................................................................................EN-6

3. MOISTURE ANALYZER SETUP .....................................................................................EN-7

3.1 Language Settings ......................................................................................................EN-7

3.2 Weight Calibration ......................................................................................................EN-8

3.3 Temperature Calibration ...............................................................................................EN-9

3.4 Time and Date Setting................................................................................................EN-10

3.5 RS232 Settings.........................................................................................................EN-11

3.6 Setting Print and GLP Printing On or Off........................................................................EN-12

3.7 Adjusting Display Contrast and Brightness....................................................................EN-13

4. OPERATING YOUR MOISTURE ANALYZER ...................................................................EN-14

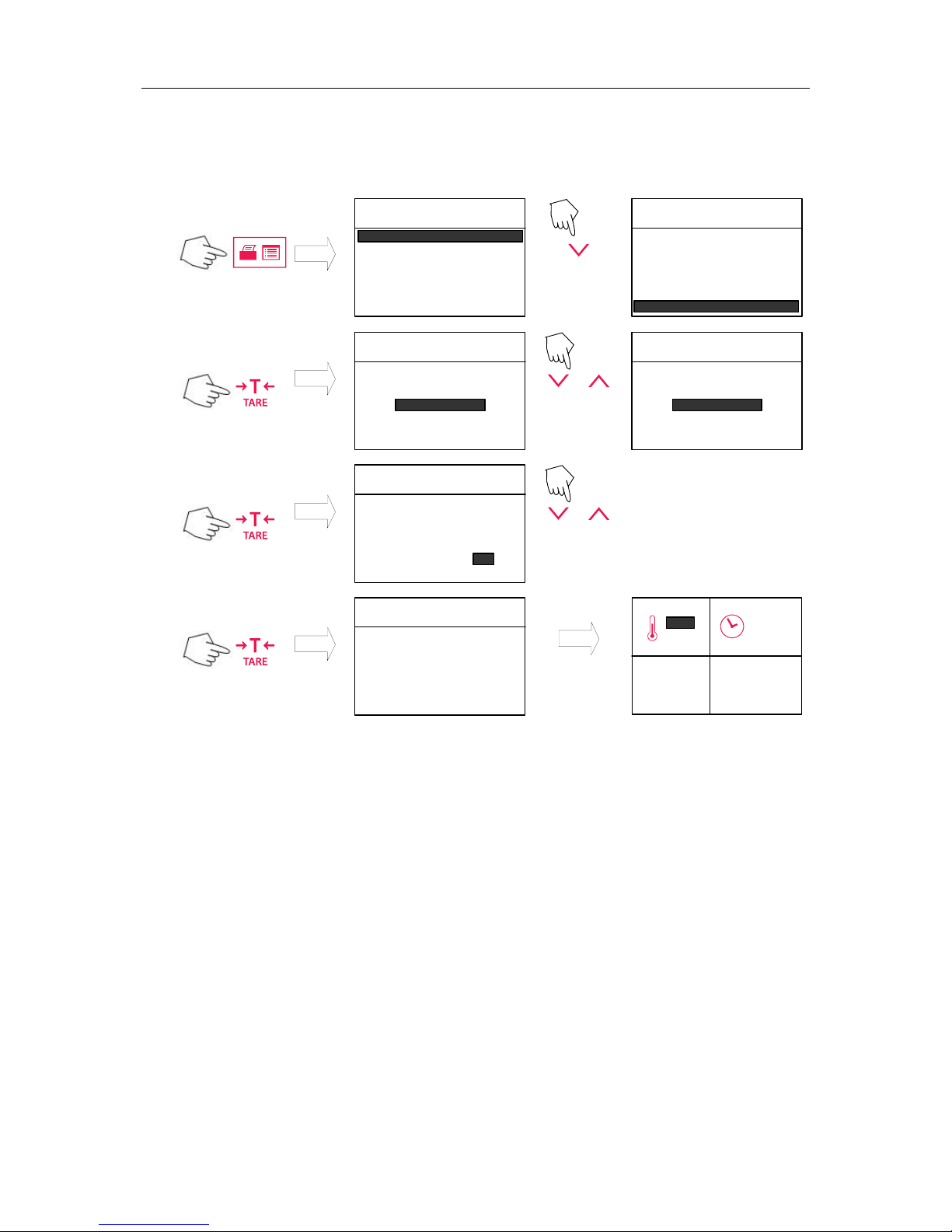

4.1 Setting the Drying Temperature....................................................................................EN-14

4.2 Setting the Drying Time ..............................................................................................EN-14

4.3 Sample Preparation...................................................................................................EN-14

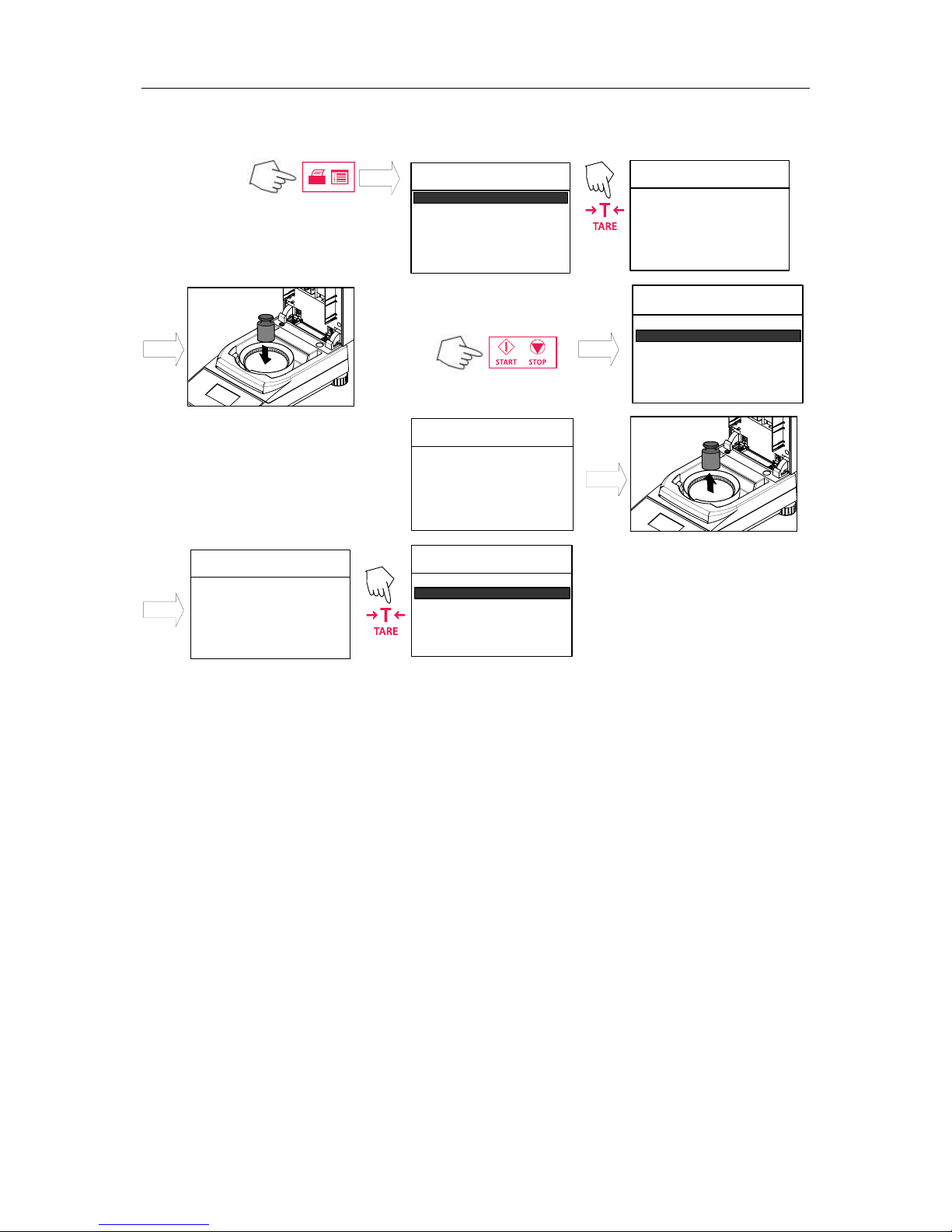

4.4 Running the Test.......................................................................................................EN-15

4.5 RS232 Command Table ............................................................................................EN-16

5. CARE AND MAINTENANCE ........................................................................................EN-17

5.1 Cleaning Interior/Exterior Components..........................................................................EN-17

5.2 Replacing Power Line Fuse ........................................................................................EN-18

5.3 Resetting the Dryer Thermal Overload Device ................................................................EN-18

5.4 Accessories..............................................................................................................EN-19

5.5 Specifications...........................................................................................................EN-19

6. COMPLIANCE ..........................................................................................................EN-20