i

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION

Page

1. Introduction ........................................................................................................ 1-1

1.1 Service Facilities .................................................................................................. 1-1

1.2 Tools and Equipment ........................................................................................... 1-2

1.2.1 Standard Tools and Test Equipment .......................................................... 1-2

1.2.2 Special Tools ......................................................................................... 1-2

1.3 Calibration Masses Required................................................................................. 1-2

1.4 Service Strategy ................................................................................................... 1-3

1.5 Safety and Environmental Protection ...................................................................... 1-3

CHAPTER 2 DIAGNOSIS

2. Diagnosis .......................................................................................................... 2-1

2.1 Basic Examination .............................................................................................. 2-1

2.2 Preliminary Checks .............................................................................................. 2-1

2.3 Troubleshooting Tables ........................................................................................ 2-1

2.4 Error Code Table .................................................................................................. 2-6

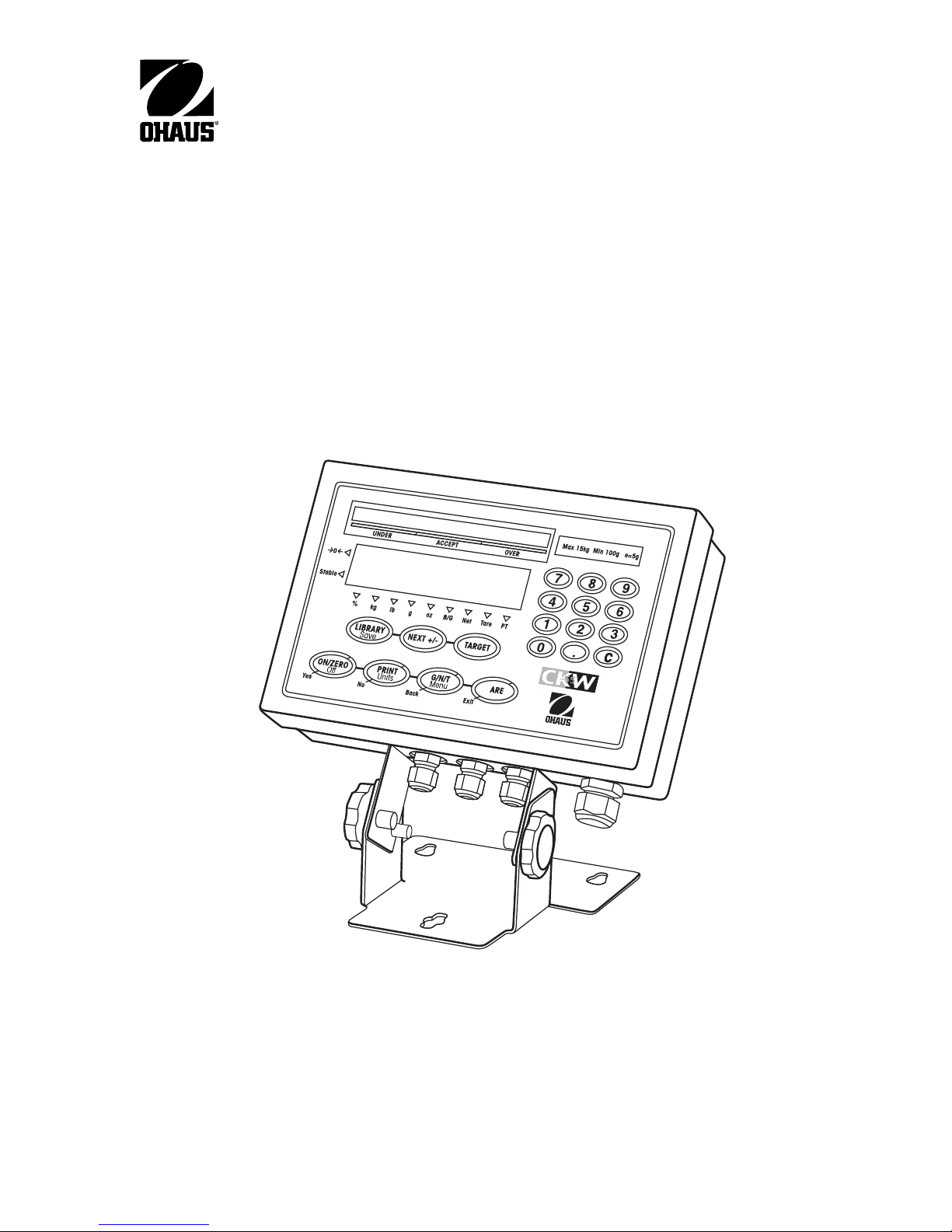

CHAPTER 3 CKW-55 INDICATOR TESTING

3. Indicator Testing.................................................................................................. 3-1

3.1 Membrane Switch Testing ..................................................................................... 3-1

3.2 Main PC Board Testing......................................................................................... 3-3

3.2.1 Voltage Measurements ............................................................................ 3-3

3.2.2 Simulator Testing .................................................................................... 3-6

3.3 Power Supply Testing ........................................................................................... 3-7

3.3.1 Voltage measurements ............................................................................ 3-7

3.4 Battery Testing .................................................................................................... 3-8

3.4.1 General Information ................................................................................ 3-8

3.4.2 Troubleshooting the Battery ...................................................................... 3-9

3.5 Recharge Board Testing ..................................................................................... 3-10

3.5.1 Recharge Board Information................................................................... 3-10

3.5.2 Recharge Board Testing......................................................................... 3-11

3.5.3 Voltage Measurements .......................................................................... 3-12

3.6 Relay Board Testing ........................................................................................... 3-13

3.6.1 Relay Kit Information ............................................................................. 3-13

3.6.2 Relay Testing........................................................................................ 3-13

3.7 RS322, RS422/485 Communication Testing ........................................................ 3-16

3.7.1 RS422/485 Communication Board Information ........................................ 3-16

3.7.2 RS232 Testing...................................................................................... 3-16

3.7.3 RS422/485 Testing............................................................................... 3-18

3.8 External Input Testing ......................................................................................... 3-20

3.9 Operational Testing ............................................................................................ 3-21

3.9.1 Indicator Display Segment Test- Power On Sequence ................................ 3-21

3.9.2 Turning Off the Indicator ......................................................................... 3-22

3.9.3 Performance Testing ............................................................................. 3-22

3.9.4 Checking Menu Library Settings .............................................................. 3-23