TABLE OF CONTENTS

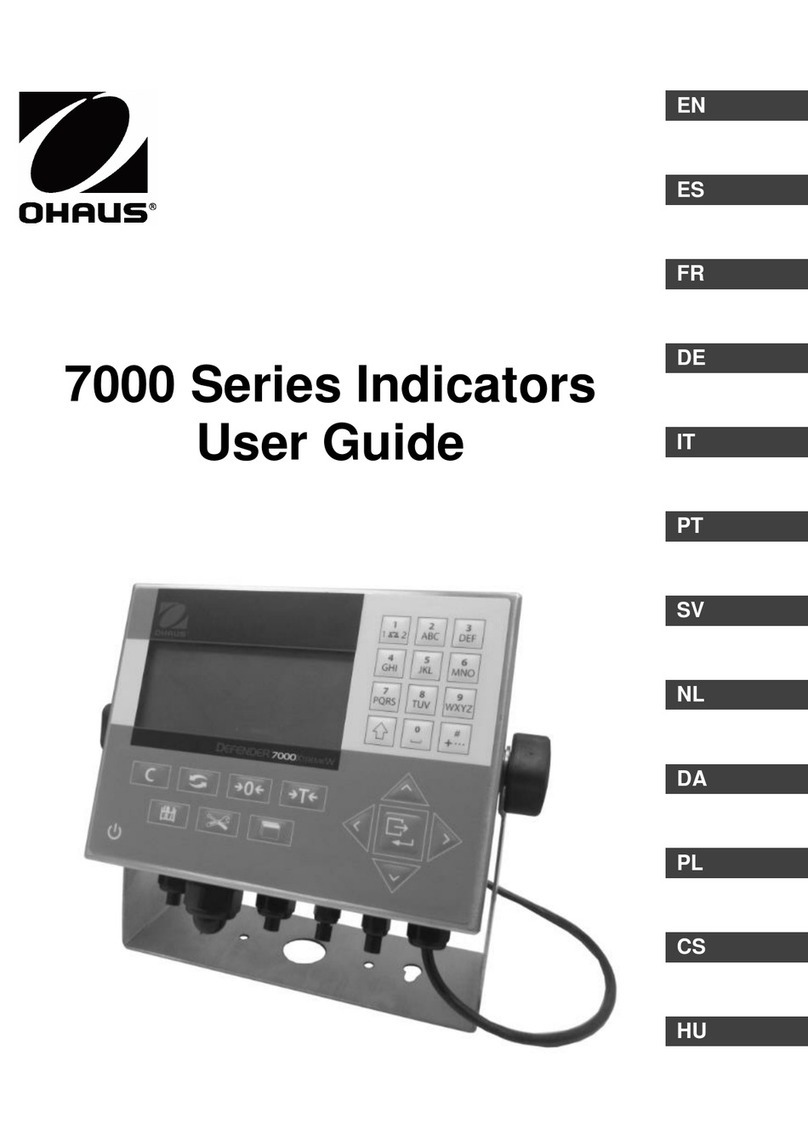

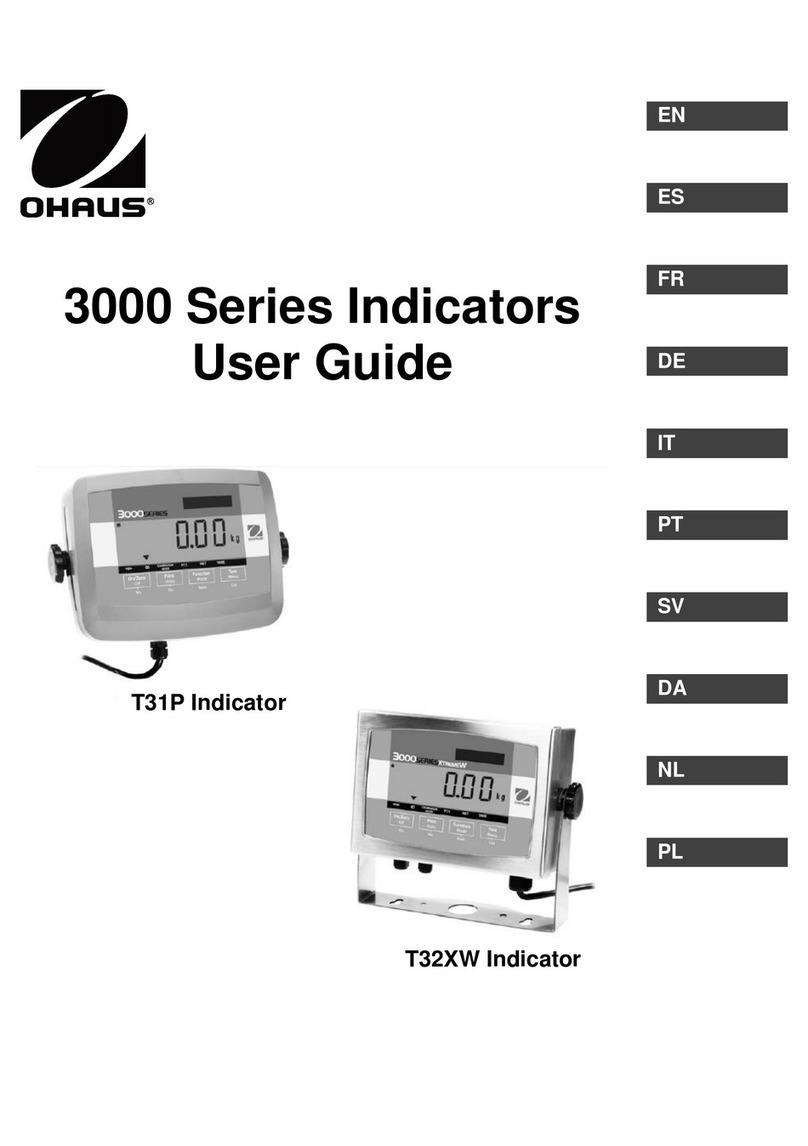

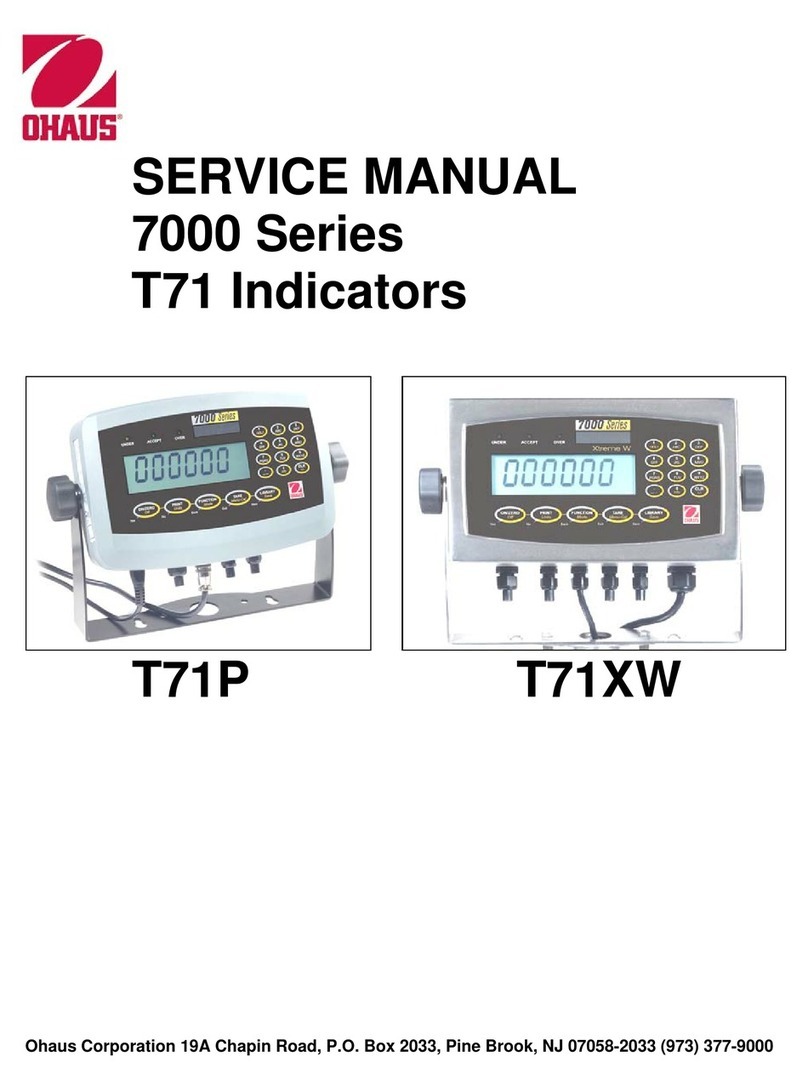

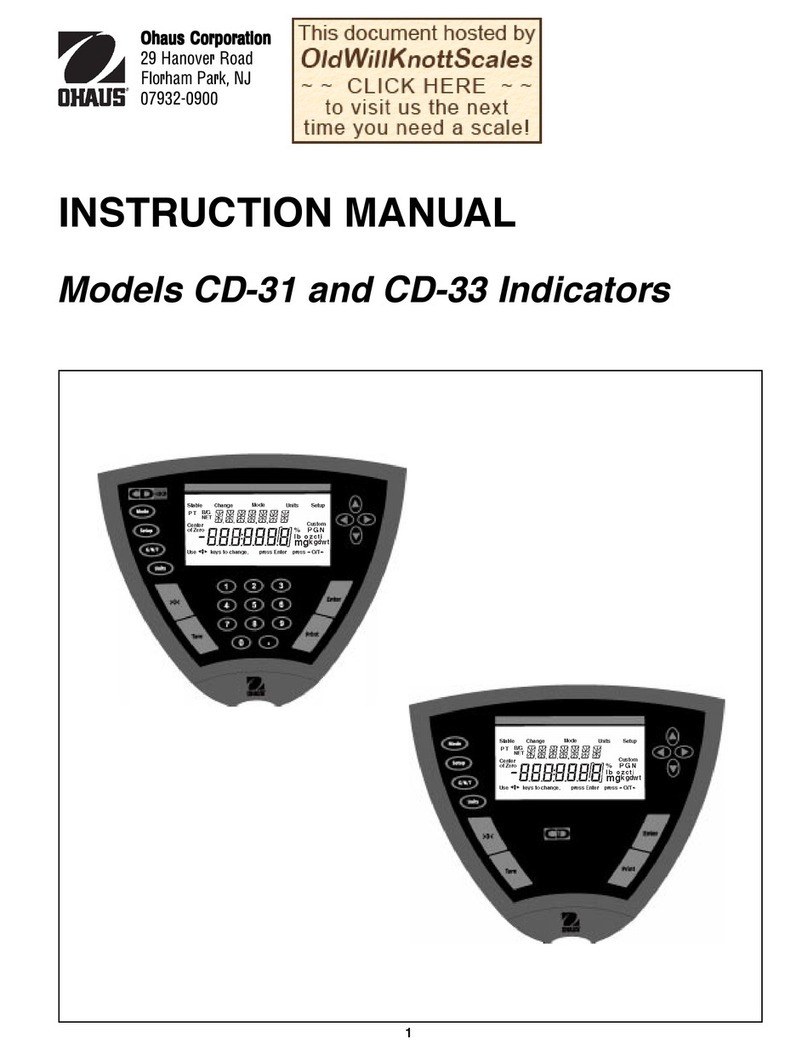

3000 Series T32ME & MC Indicators Service Manual iOhaus Corporation www.ohaus.com

CHAPTER 1 GETTING STARTED Page No.

1.1 Introduction................................................................................................................1-1

1.2 Service Facilities........................................................................................................1-1

1.3 Tools and Test Equipment Required.........................................................................1-2

1.3.1 Special Tools and Test Equipment List..............................................................1-2

1.3.2 Standard Tools and Test Equipment List ...........................................................1-2

1.4 Specifications.............................................................................................................1-3

1.5 Hardware Setup or Disassembly...............................................................................1-4

1.5.1 Jumper Connections ..........................................................................................1-5

1.5.2 RS232 Interface .................................................................................................1-5

1.6 Overview of the Controls ...........................................................................................1-6

1.7 Operation...................................................................................................................1-7

1.7.1 Power On ...........................................................................................................1-7

1.7.2 Power Off ...........................................................................................................1-7

1.7.3 Menu Setup........................................................................................................1-7

1.8 RS232 Interface Connection......................................................................................1-8

1.8.1 Setting Communications Parameters.................................................................1-8

1.8.2 Interface Commands..........................................................................................1-9

1.8.3 Output Format ....................................................................................................1-9

1.9 Legal For Trade (LFT) .............................................................................................1-10

CHAPTER 2 TROUBLESHOOTING

2.1 Introduction................................................................................................................2-1

2.2 Visual Inspection........................................................................................................2-1

2.3 Error Codes ...............................................................................................................2-2

2.4 Problem Solver..........................................................................................................2-3

CHAPTER 3 MAINTENANCE PROCEDURES

3.1 Preventive Maintenance............................................................................................3-1

3.1.1 Preventive Maintenance Checklist .....................................................................3-1

3.2 Testing and Replacement of Major Components ......................................................3-1

3.3 Testing the Printed Circuit Board (PCB)....................................................................3-2

3.3.1 PCB Voltage Measurements............................................................................3-2

3.3.2 Simulator Testing .............................................................................................3-2

3.3.2.1 How Strain Gauge Load Cells Operate....................................................3-3

3.3.2.2 How to Operate Simulators ......................................................................3-4

3.3.2.3 Correcting Underload and Overload Errors..............................................3-5

3.3.2.4 General Load Test....................................................................................3-5

3.3.2.5 Calibration Test ........................................................................................3-5

3.4 Replacing the Printed Circuit Board (PCB)................................................................3-6

3.5 Cable Set Replacement.............................................................................................3-6

3.6 Function Label Replacement.....................................................................................3-7

CHAPTER 4 TESTING

4.1. Testing.......................................................................................................................4-1

4.2 Power Test.................................................................................................................4-1

4.3 Performance Tests Using a Scale Base....................................................................4-1

4.3.1 Overload/Underload Test ...................................................................................4-2

4.4 Performance Tests Using a Load Cell Simulator.......................................................4-2

4.5 Calibration Retention Test.........................................................................................4-2

4.6 RS232 Interface Test/Print Test ................................................................................4.2