2

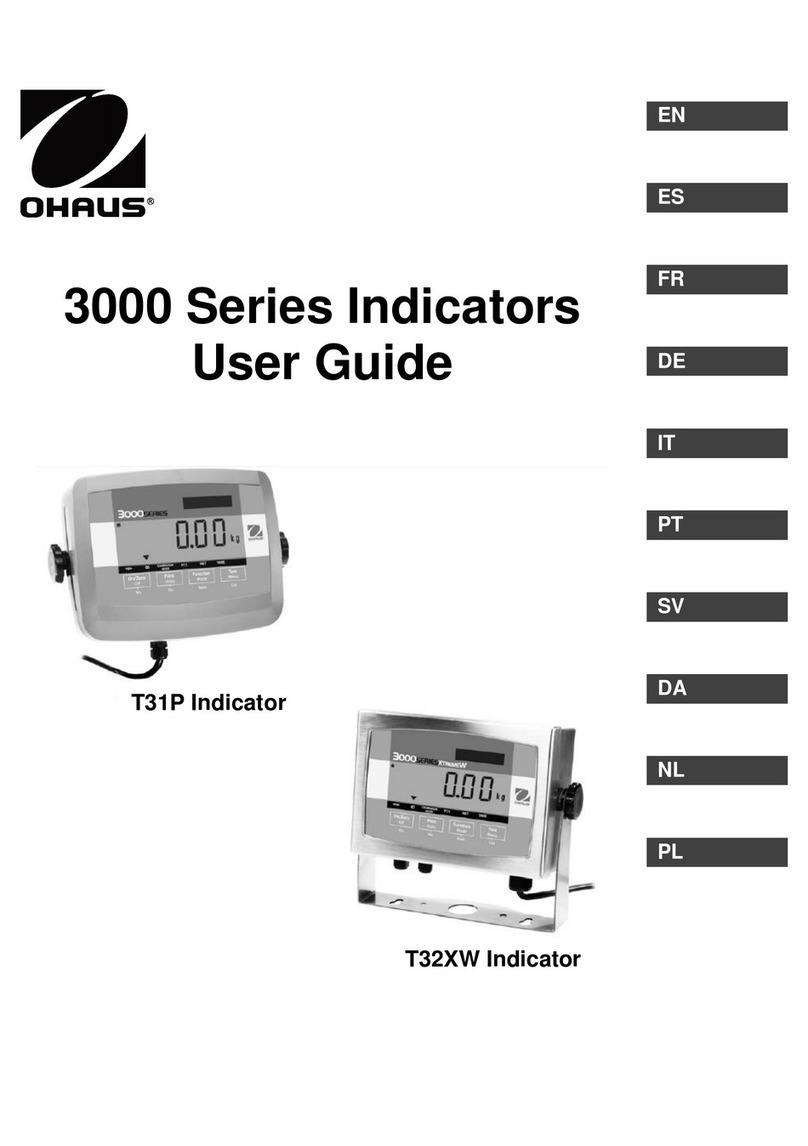

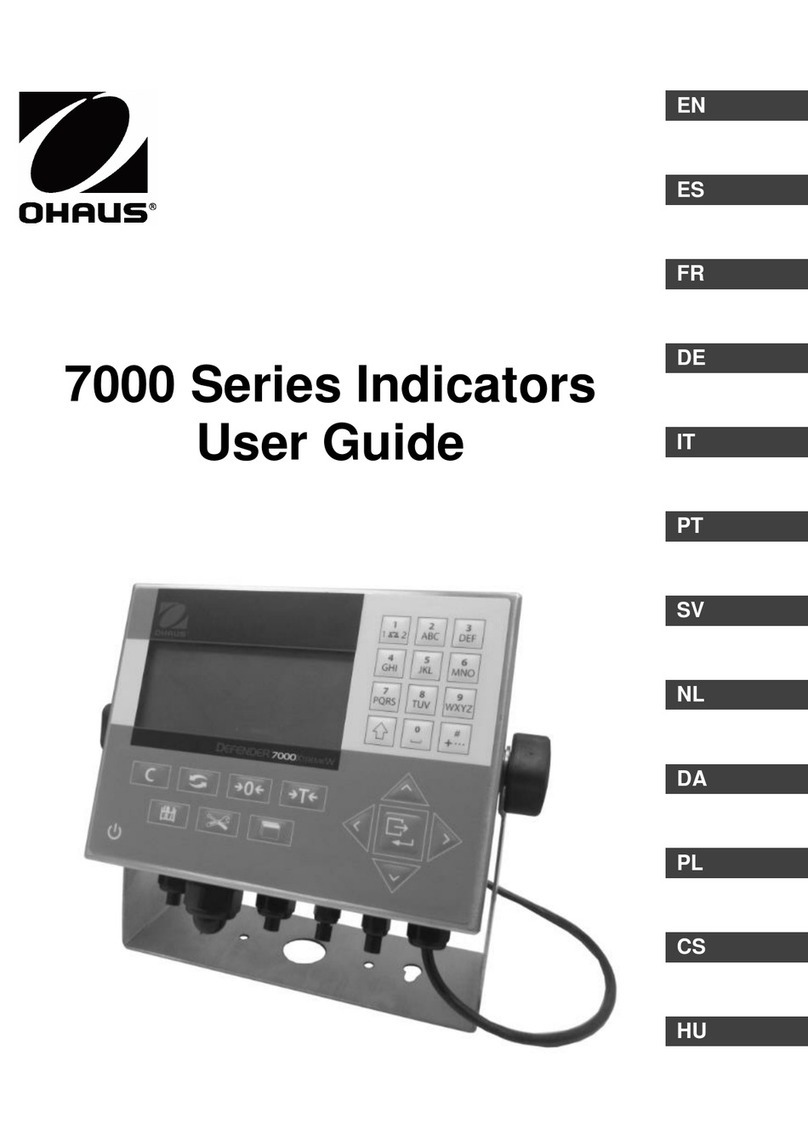

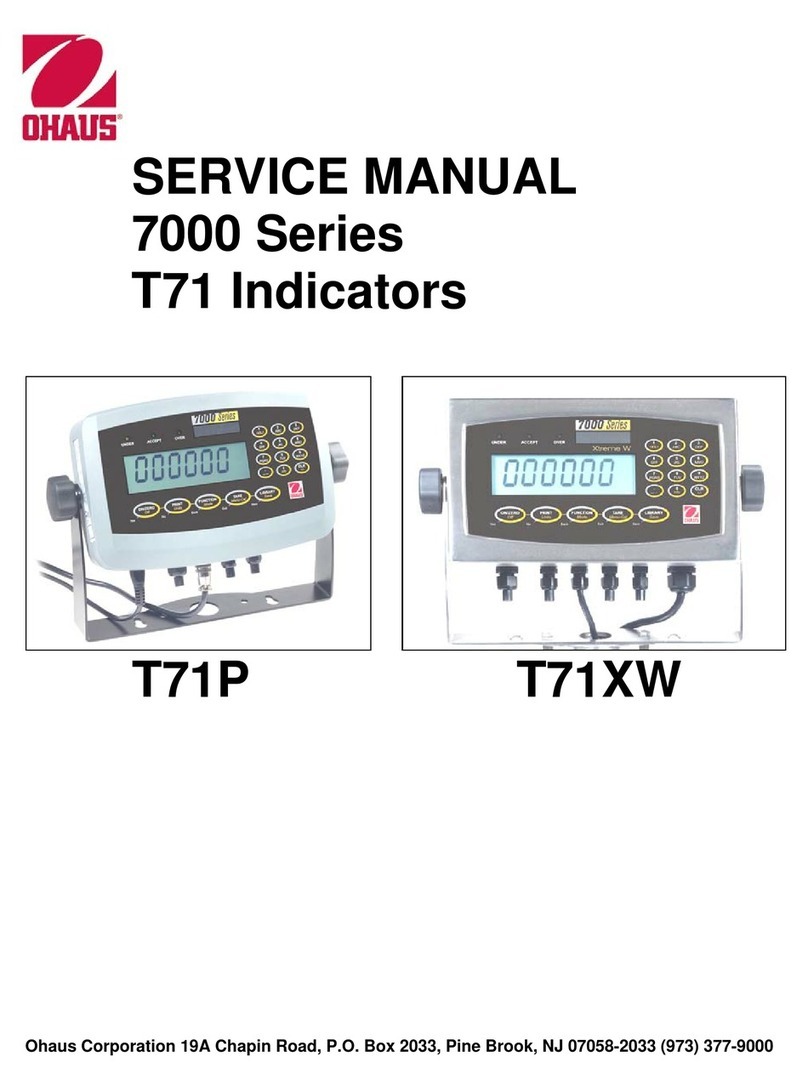

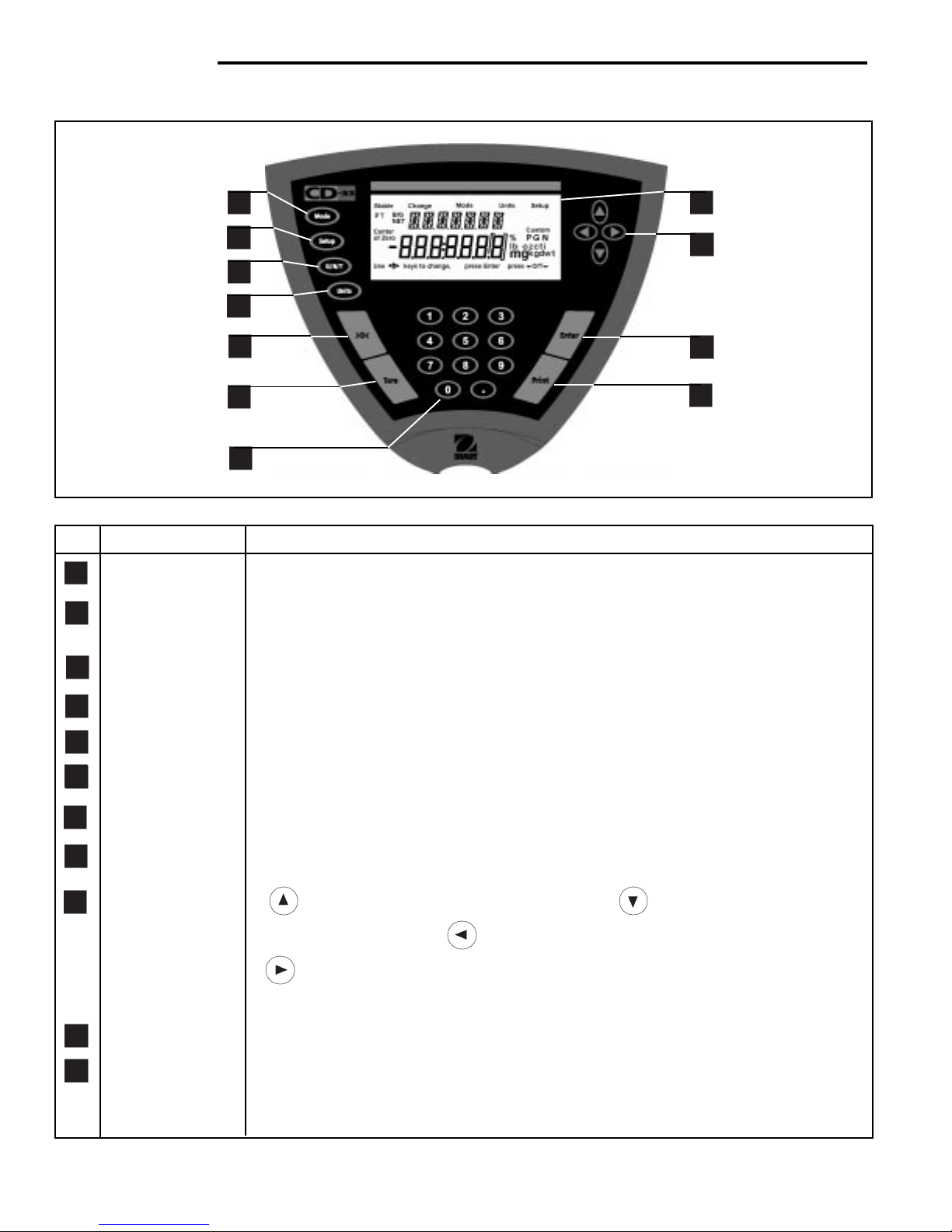

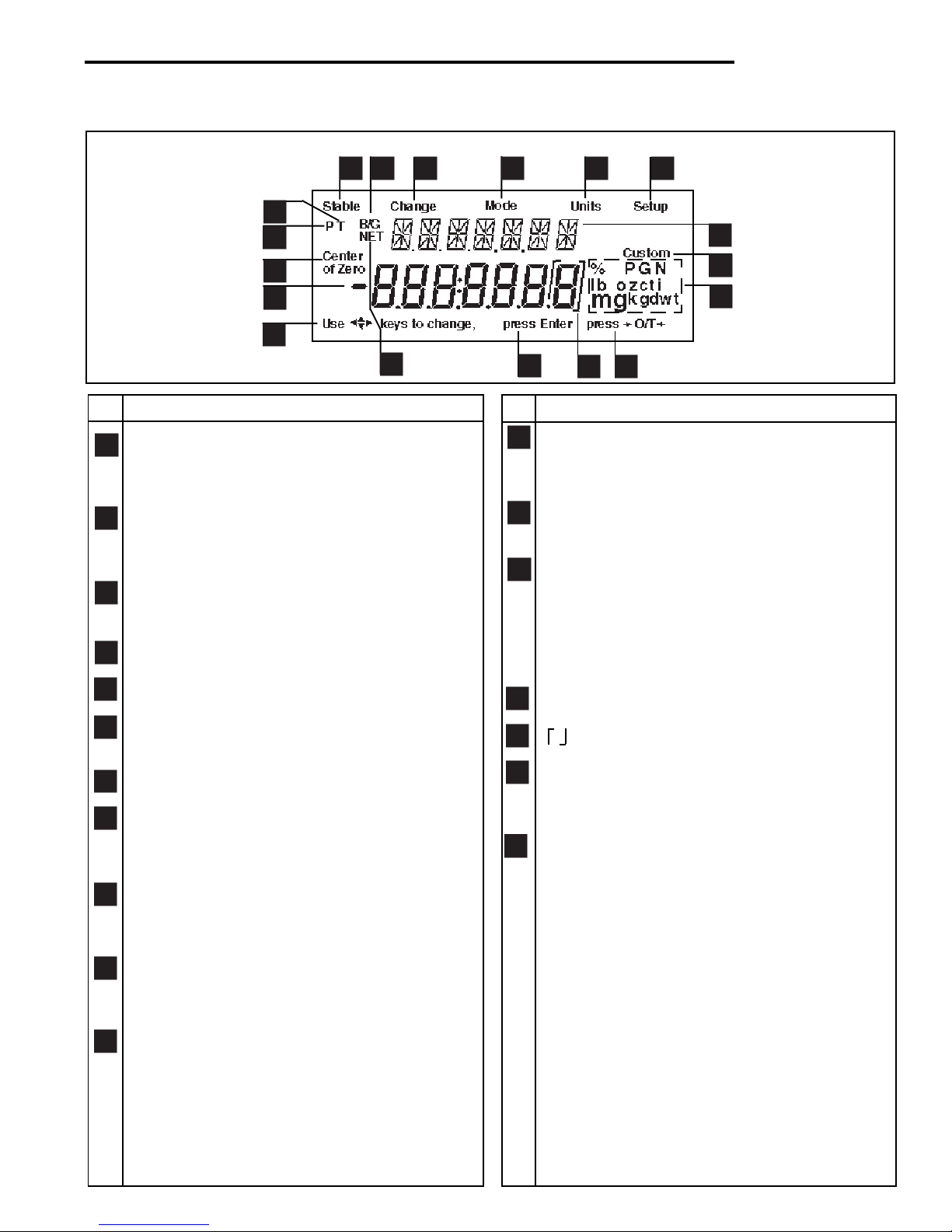

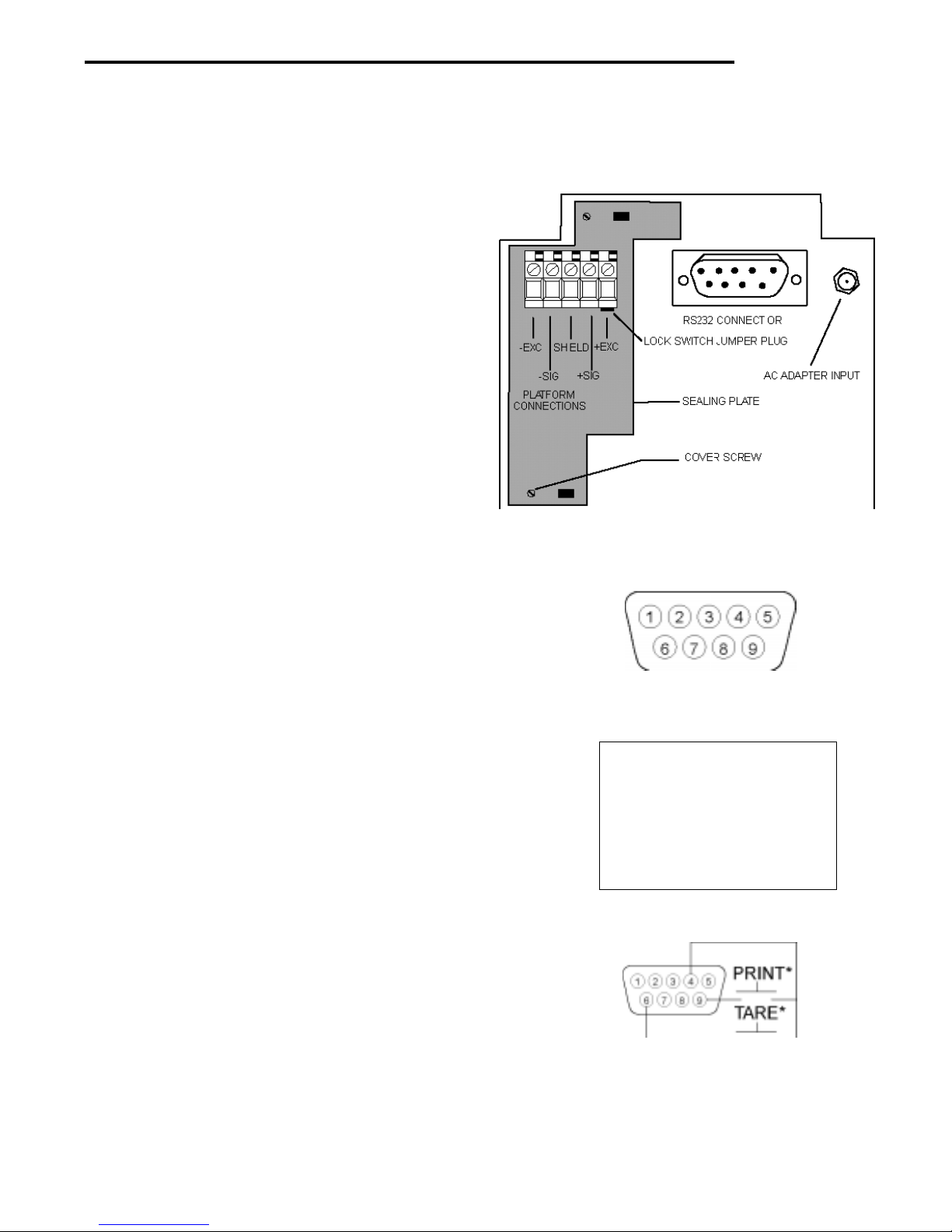

CD Indicators

IEC1010-1 & EN60950:1992 Safety Regulations

IEC1010-1 & EN60950:1992 Sicherheitsbestimmungen

IEC1010-1 & EN60950:1992 Consignes de sécurité

IEC1010-1 & EN60950:1992 Disposiciones sobre seguridad

IEC1010-1 & EN60950:1992 Prescrizioni . di sicurezza

EN55022:1987 Emissions

EN50082-1:1992 Immunity

NOTE: The displayed value may be adversely affected under

extreme electromagnetic influences, eg. when using a radio unit in the

immediate vicinity of the device. Once the interference has been

rectified, the product can once again be used for its intended purpose.

EN55022:1987 Funkstörungen

EN50082-1:1992 Immunität

Hinweis: Unter extremen elektromagnetischen Einflüssen z.B. bei

Betreiben eines Funkgerätes in unmittelbarer Nähe des Gerätes kann

eine Beeinflussung des Anzeigewertes verusacht werden. Nach Ende

des Störeinflusses ist das Produkt wieder bestimmungsgemäss

benutzbar.

EN55022:Emissions parasites

EN50082-1:1992 Immunité

Remarque: Dans des conditions d'influences électromagnètiques

extrêmes, par exemple en cas d'exploitation d'un appareil radio à

proximité immédiate de l'appareil la valeur d'affichage risque d'être

influencée. Une fois que l'influence parasite est terminée, le produit

peut être de nouveau utilisé de manière conforme aux prescriptions.

EN55022:1987 Radiointerferencias

EN50082-1:1992 Inmunidad

Nota: Bajo influencias electromagnèticas extremas, p.ej. cuando

funciona una radio en las inmediaciones del aparato, se pueden

alterar los valores del display. Cuando concluye el efecto perturbador,

el producto puede ser utilizado de nuevo, de acuerdo con lo

estipulado.

EN55022:1987 Radiointerferenze

EN50082-1:1992 Immunità

Nota: ll valore visualizzato può essere influenzato negativamente dalla

presenza di forti interferenze elettromagnetiche, per esempio quando

viene usata una radio in prossimità della bilancia. Eliminata la fonte

dell'interferenza, il prodotto può essere nuovamente utilizzato per le

funzioni cui è preposto.

EU 73/23 Low Voltage

EU 73/23 Niederspannung

EU 73/23 Basse tension

EU 73/23 Baja tensión

EU 73/23 Bassa tensione

EU 89/336, 92/31, 93/68

Electromagnetic compatibility

EU 89/336, 92/31, 93/68

Elektromagnetische Verträglichkeit

EU 89/336, 92/31, 93/68

Compatibilité électromagnétique

EU 89/336, 92/31, 93/68

Compatibilidad electromagnética

EU 89/336, 92/31, 93/68

Compatibilità elettromagnetica

Ohaus Corporation, 29 Hanover Road, Florham Park, New Jersey, 07932, USA

Declaration of Conformity We, Ohaus Corporation, declare under our sole responsibility that the instrument models listed below marked with

“CE” - are in conformity with the directives and standards mentioned.

Konformitätserkärung Wir, die Ohaus Corporation, erklären in alleiniger Verantwortung, dass die untenstehenden Waagentypen, instrument

mit “CE” - mit den genannten Richtlinien und Normen übereinstimmen.

Déclaration de conformité Nous, Ohaus Corporation, déclarons sous notre seule responsabilité, que les types de instrument ci-dessous cité

- munis de la mention «CE» - sont conformes aux directives et aux normes mentionnées ci-après.

Declaración de Conformidad Nostras, Ohaus Corporation, declaramos bajo responsabilidad exclusiva que los modelos de instrumento

indicados a continuación - con el distintivo ,CE’ - están conformes con las directivas y normas citadas.

Dichiarazione di conformità Noi, Ohaus Corporation, U.S.A, dichiariamo sotto nostra unica responsabilità, che i tipi di strumento specificati di

seguito - contrassegnati con la marcatura “CE” - sono conformi alle direttive e norme citate.

Instrument Type/Waagentyp/Type de instrument/Modelo de instrumento/Tipo di strumento CD-31/CD-33 Indicators

Marked with: Directive Standard

Gekennzeichnet mit: Richtlinie Norm

Munis de la mention: Directive Norme

Con el distintivo: Directiva Norma

Contrassegnati con la Direttiva Norma

Marcatura: