TABLE OF CONTENTS

CHAPTER 1 GETTING STARTED Page No.

1.1 Introduction................................................................................................................1-1

1.2 Service Facilities........................................................................................................1-1

1.3 Tools and Test Equipment Required.........................................................................1-2

1.3.1 Special Tools and Test Equipment List..............................................................1-2

1.3.2 Standard Tools and Test Equipment List ...........................................................1-2

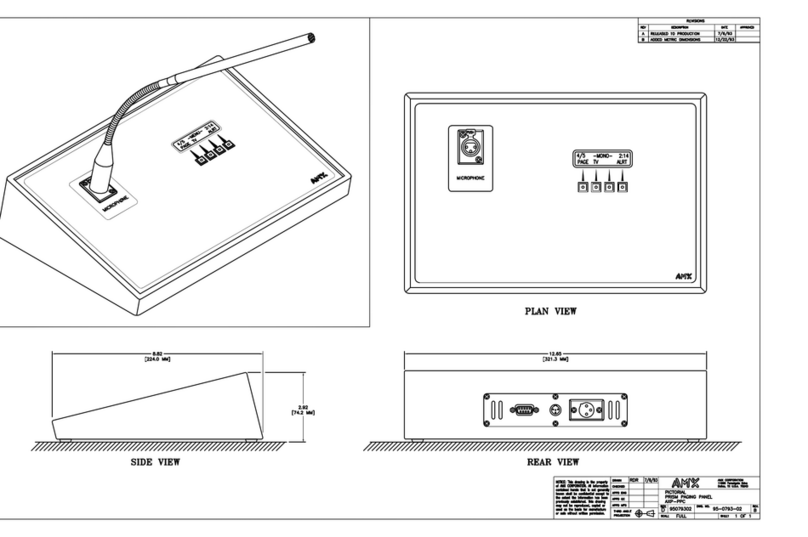

1.4 T71P and T71XW: Top and Bottom Housing ............................................................1-2

1.5 Specifications.............................................................................................................1-4

1.6 Hardware Setup or Disassembly...............................................................................1-5

1.6.1 Connecting the Scale Base’s Load Cell.............................................................1-5

1.6.2 Jumper Connections ..........................................................................................1-6

1.6.3 RS232 Interface .................................................................................................1-6

1.7 Operation...................................................................................................................1-7

1.7.1 Power Supply.....................................................................................................1-7

1.7.2 Overview of the Controls....................................................................................1-7

1.7.3 Overview of the Display Indicators.....................................................................1-7

1.7.4 Overview of the Control Functions .....................................................................1-8

1.7.5 Menu Setup........................................................................................................1-9

1.7.6 Language Menu Setup.....................................................................................1-12

1.8 Calibration................................................................................................................1-13

1.8.1 Zero Calibration................................................................................................1-13

1.8.2 Span Calibration...............................................................................................1-14

1.8.3 3-point Linearity Calibration..............................................................................1-15

1.8.4 5-point Linearity Calibration..............................................................................1-16

1.8.5 Calibration Test ................................................................................................1-17

1.8.6 Geographical Adjustment Factor......................................................................1-17

1.9 RS232 Interface Connection....................................................................................1-18

1.9.1 Setting Communications Parameters...............................................................1-18

1.9.2 Interface Commands........................................................................................1-19

1.9.3 Output Format..................................................................................................1-20

1.10 Legal For Trade (LFT) .............................................................................................1-21

CHAPTER 2 TROUBLESHOOTING

2.1 Introduction................................................................................................................2-1

2.2 Visual Inspection........................................................................................................2-1

2.3 Diagnostic Guide .......................................................................................................2-2

2.2.1 Diagnosis............................................................................................................2-2

CHAPTER 3 MAINTENANCE PROCEDURES

3.1 Preventive Maintenance............................................................................................3-1

3.1.1 Preventive Maintenance Checklist .....................................................................3-1

3.2 Replacement of Major Components..........................................................................3-1

3.2.1 Main Printed Circuit Board (PCB) Replacement.................................................3-2

3.2.1 Display Printed Circuit Board (PCB) Replacement.............................................3-3

3.2.3 Membrane Switch Replacement.........................................................................3-4

CHAPTER 4 TESTING

4.1. Testing.......................................................................................................................4-1

4.2 Power Test.................................................................................................................4-1

4.3 Performance Tests Using a Scale Base....................................................................4-1

Ohaus Corporation www.ohaus.com 1 7000 Series T71 Indicators Service Manual