44205301TH Rev.1 4 /

Oki Data CONFIDENTIAL

Index

1. Configuration...........................................................................6

1.1 System configuration............................................................................................7

1.2 The Configuration of printer..................................................................................8

1.3 Optional parts.......................................................................................................9

1.4 Specifications .....................................................................................................10

1.5 Specification of interface ....................................................................................13

1.5.1 Specification of USB interface ....................................................................13

1.5.1.1 General of USB interface.....................................................................13

1.5.1.2 Connector and cable of USB interface.................................................13

1.5.1.3 USB interface signal ............................................................................13

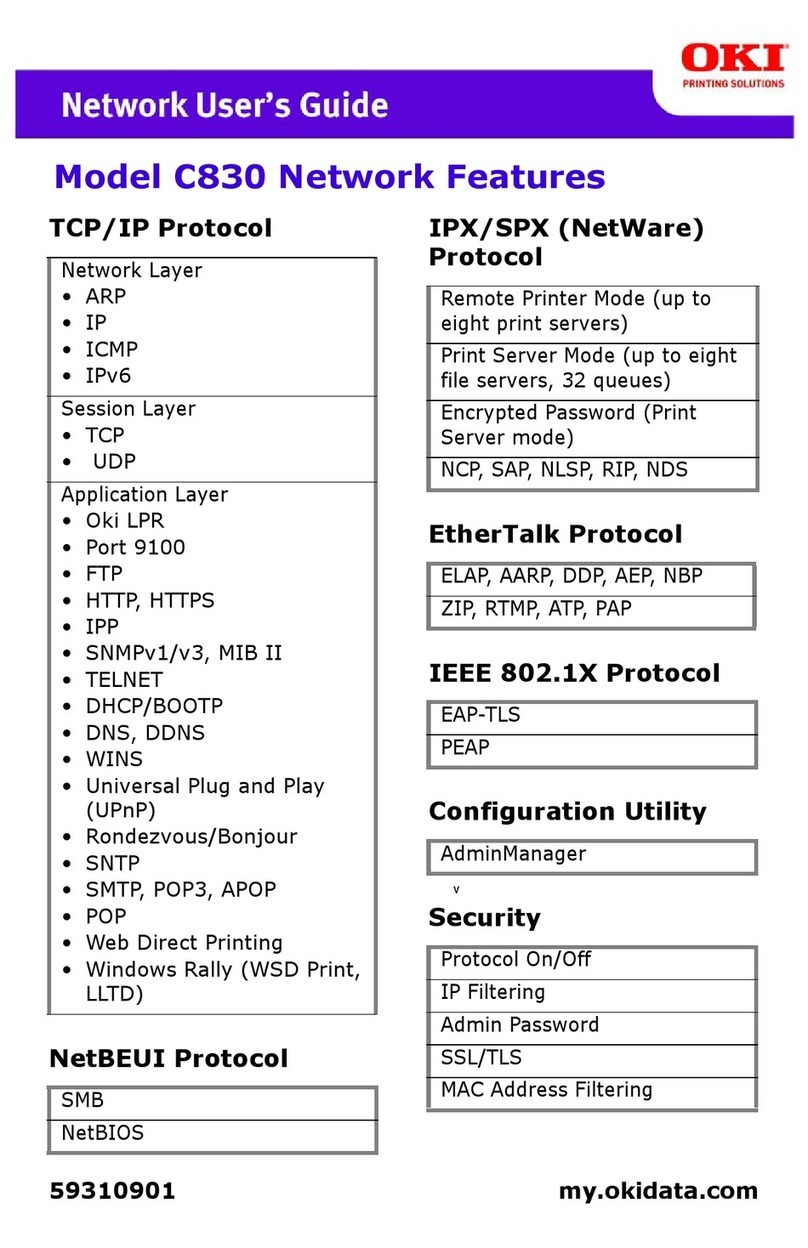

1.5.2 Specification of network interface...............................................................14

1.5.2.1 General of network interface................................................................14

1.5.2.2 Connector and cable of network interface ...........................................14

1.5.2.3 Signal of network interface ..................................................................14

1.5.3 Specification of ACC interface ....................................................................15

2. Operating instructions..........................................................16

2.1 Electrophotographic processing mechanism......................................................17

2.2 Printing process..................................................................................................21

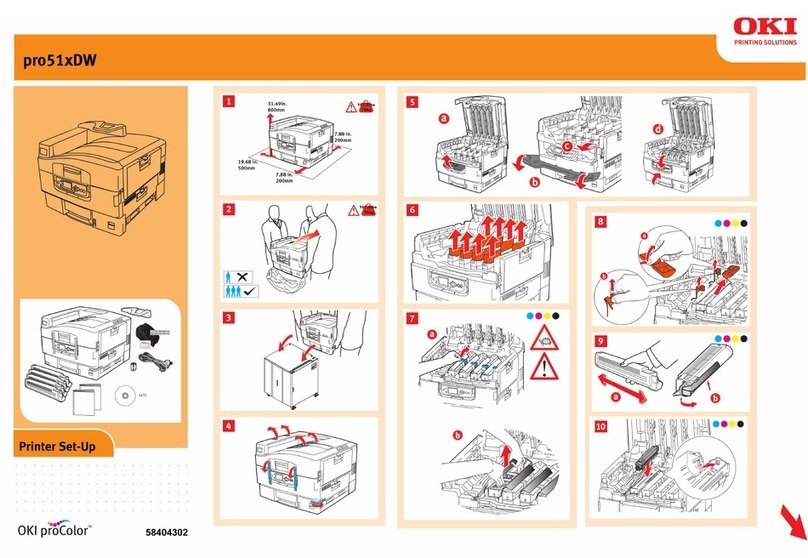

3. Set up .....................................................................................32

3.1 Notes and precautions........................................................................................33

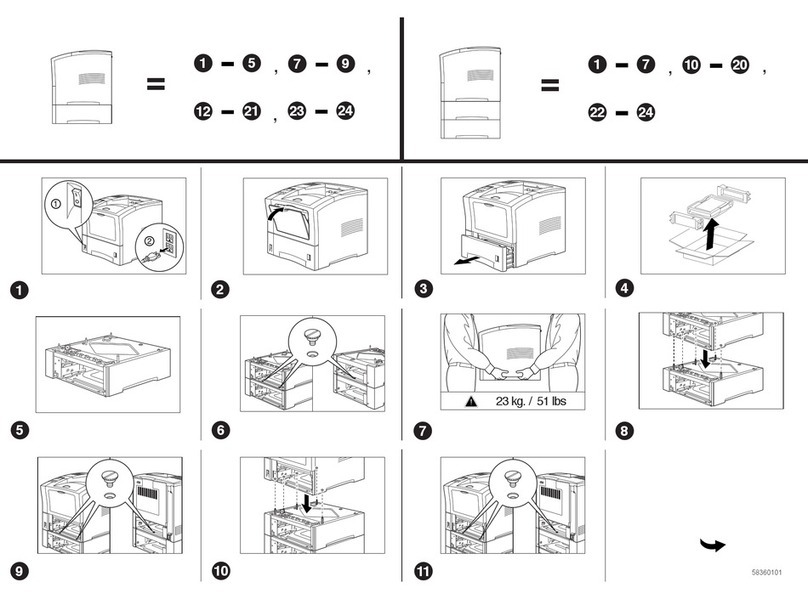

3.2 Unpack method ..................................................................................................34

3.3 Setting method ...................................................................................................35

3.4 List of equipments and accessories ...................................................................36

3.5 Assembling method............................................................................................37

3.5.1 Assemble the main body of the printer .......................................................37

3.5.2 Cable connect.............................................................................................43

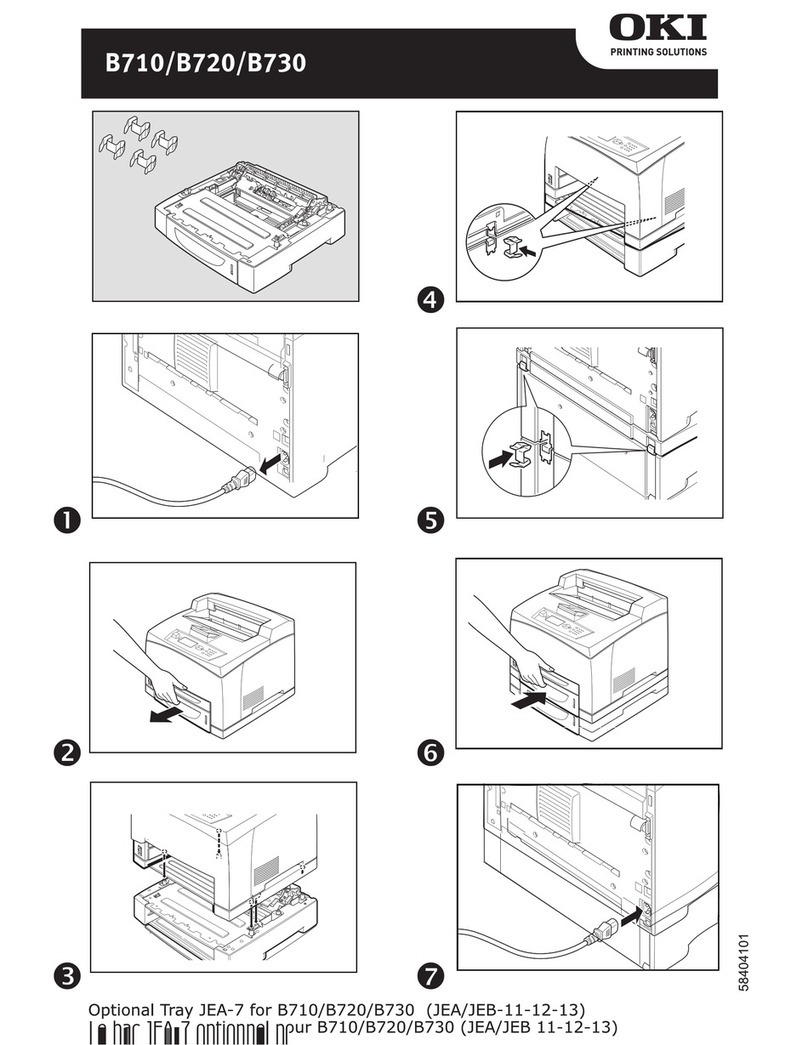

3.5.3 Optional part installation and confirmation..................................................45

3.6 Setting content print (Configuration)...................................................................56

3.7 Connecting method ............................................................................................57

3.8 User used Paper confirmation............................................................................59

4. Component replacement......................................................60

4.1 Precautions on component replacement............................................................61

4.2 Method of component replacement....................................................................63

4.2.1 Belt unit.......................................................................................................63

4.2.2 Fuser unit....................................................................................................64

4.2.3 Left side cover.............................................................................................64

4.2.4 Right side cover ..........................................................................................65

4.2.5 Faceup tray ................................................................................................65

4.2.6 Rear cover...................................................................................................66

4.2.7 LED Assy/ LED Assy spring........................................................................66

4.2.8 Control PCB................................................................................................67

4.2.9 Top cover Assy............................................................................................68

4.2.10 Top cover ....................................................................................................69

4.2.11 Control panel Assy .....................................................................................69

4.2.12 Board PRG/ LCD........................................................................................70

4.2.13 Frame panel Assy.......................................................................................71

4.2.14 Low voltage power supply/Low voltage FAN/ Hopping motor/ Fuse motor.72

4.2.15 Guide eject Assy/ Color regist Assy/ Board-PRY .......................................73

4.2.16 FAN(Fuser) / Belt motor/ High-voltage board/ Cover open switch ..............74

4.2.17 MPT Assy...................................................................................................74

4.2.18 Cover Assy front/ Board-RSF/MPT hopping roller/

Frame Assy separator/ Feeder Assy regist.................................................75

4.2.19 Board-PRZ/ Liftup motor/ Hopping motor//Paper end sensor/

Hopping sensor...........................................................................................76

4.2.20 Feed roller...................................................................................................77

4.2.21 Shaft eject Assy (FU)/ Shaft eject Assy(FD/ Eject sensor ..........................78

4.3 Oiling spots.........................................................................................................79

5. Maintenance Menu................................................................90

5.1 System maintenance menu (for maintenance engineer) ...................................91

5.2 Maintenance Utilities ..........................................................................................93

5.3 Maintenance menu functions..............................................................................95

5.3.1 Self-diagnostic mode ..................................................................................95

5.3.1.1 Operation panel...................................................................................95

5.3.1.2 Ordinary self-diagnostic mode (level 1)...............................................97