41956001TH Rev.1 5 /

Oki Data CONFIDENTIAL

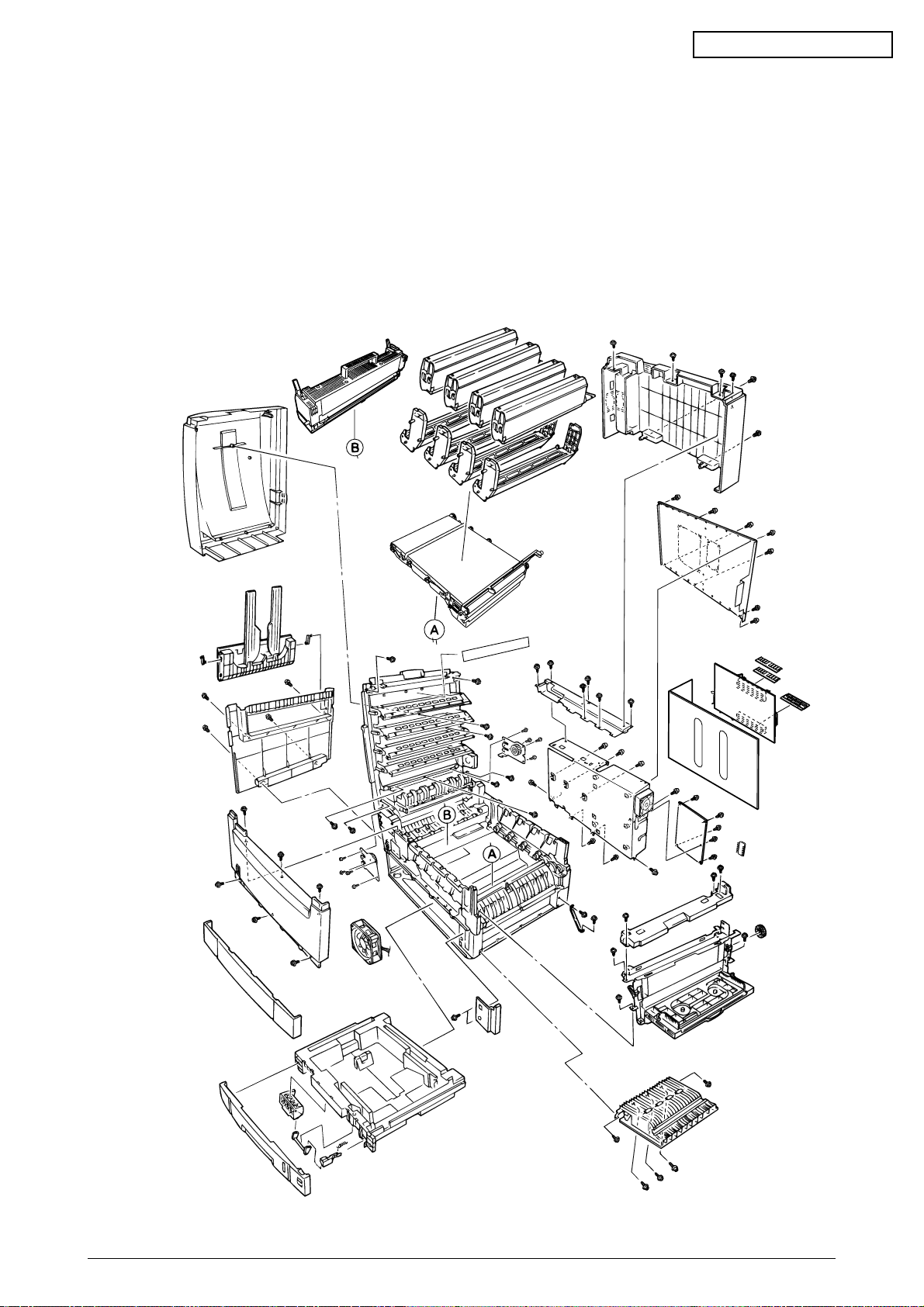

3.3.17 Registration Roller Assy (B) ............................................................................. 72

3.3.18 Registration Clutch / Registration Motor Assy .................................................. 73

3.3.19 ID Cooling Fan.................................................................................................. 74

3.3.20 Color Registration Sensor Assy........................................................................ 75

3.3.21 Duplex Guide Assy........................................................................................... 76

3.3.22 Electrical Chassis / Electrical Chassis Cooling Fan ......................................... 77

3.3.23 Print Engine Controller PWB ............................................................................ 78

3.3.24 Printer Unit Chassis.......................................................................................... 79

3.3.25 Entrance Cassette Sensor Actuator ................................................................. 80

3.3.26 Entrance Sensor PWB (R71)............................................................................ 81

3.3.27 Entrance MT Sensor Actuator / Entrance Belt Sensor Actuator /

Entrance Waste Toner Sensor Actuator.......................................................... 82

3.3.28 Main Cooling Fan (PULL) Assy / Main Cooling Fan (PUSH) /

Fuser Eject Roller ............................................................................................. 83

3.3.29 Eject Sensor Assy ............................................................................................ 84

3.3.30 Fuser Latch Handle (L)..................................................................................... 85

3.3.31 Belt Motor Assy ................................................................................................ 86

3.3.32 Fuser Latch Handle (R) .................................................................................... 87

3.3.33 Main Motor Assy............................................................................................... 88

3.3.34 Contact Assy / Side Plate Assy ........................................................................ 89

3.3.35 Low-voltage Power Unit.................................................................................... 90

3.3.36 High-voltage Power Unit................................................................................... 91

3.3.37 Main Feeder Assy............................................................................................. 92

3.3.38 Fuser Unit ......................................................................................................... 93

3.3.39 Belt Unit ............................................................................................................ 94

3.3.40 Duplex Unit ....................................................................................................... 95

3.3.41 CU Assy............................................................................................................ 96

4. Adjustment ....................................................................................................98

4.0 System Maintenance MENU.......................................................................................... 98

4.0.1 ID Check Pattern Printing ( " TEST PRINT MENU " item )............................... 99

4.1 Maintenance Mode and Functions................................................................................. 99

4.1.1 Maintenance menu........................................................................................... 99

4.1.2 Engine maintenance mode............................................................................. 101

4.1.2.1 Operator panel ................................................................................ 101

4.1.2.2 General self-diagnostic mode (Level 1) .......................................... 101

4.1.2.2.1 Entering self-diagnostic mode (Level 1).......................... 102

4.1.2.2.2 Exiting self-diagnostic mode .......................................... 102

4.1.2.3 Switch scan test .............................................................................. 102

4.1.2.4 Motor clutch test.............................................................................. 106

4.1.2.5 Test print ......................................................................................... 109

4.1.2.6 NVM initialization............................................................................. 113

4.1.2.7 Consumable counter display........................................................... 114

4.1.2.8 Consumable counter display - continuous ...................................... 114

4.1.2.9 Error Messages and their details .................................................... 115

4.1.3 Various print jobs with single printer unit attached with a controller............... 120

4.2 Adjustments after Parts Replacement ......................................................................... 121

4.2.1 Precautions in replacing engine control board ............................................... 121

4.2.2 Precautions in replacing EEPROM................................................................. 121

4.2.3 EEPROM replacement after TIG board replacement ..................................... 122

4.2.4 Destination Setting (Checking Method: Printing Demo Page)........................ 122

4.2.5 Recovery Flash ROM data on TIG board....................................................... 123

4.3 Adjusting the Density ................................................................................................... 123

4.4 Paper Thickness Detection Sensitivity Adjustment and Media Thickness Detection

Value Check................................................................................................................. 124