8

11

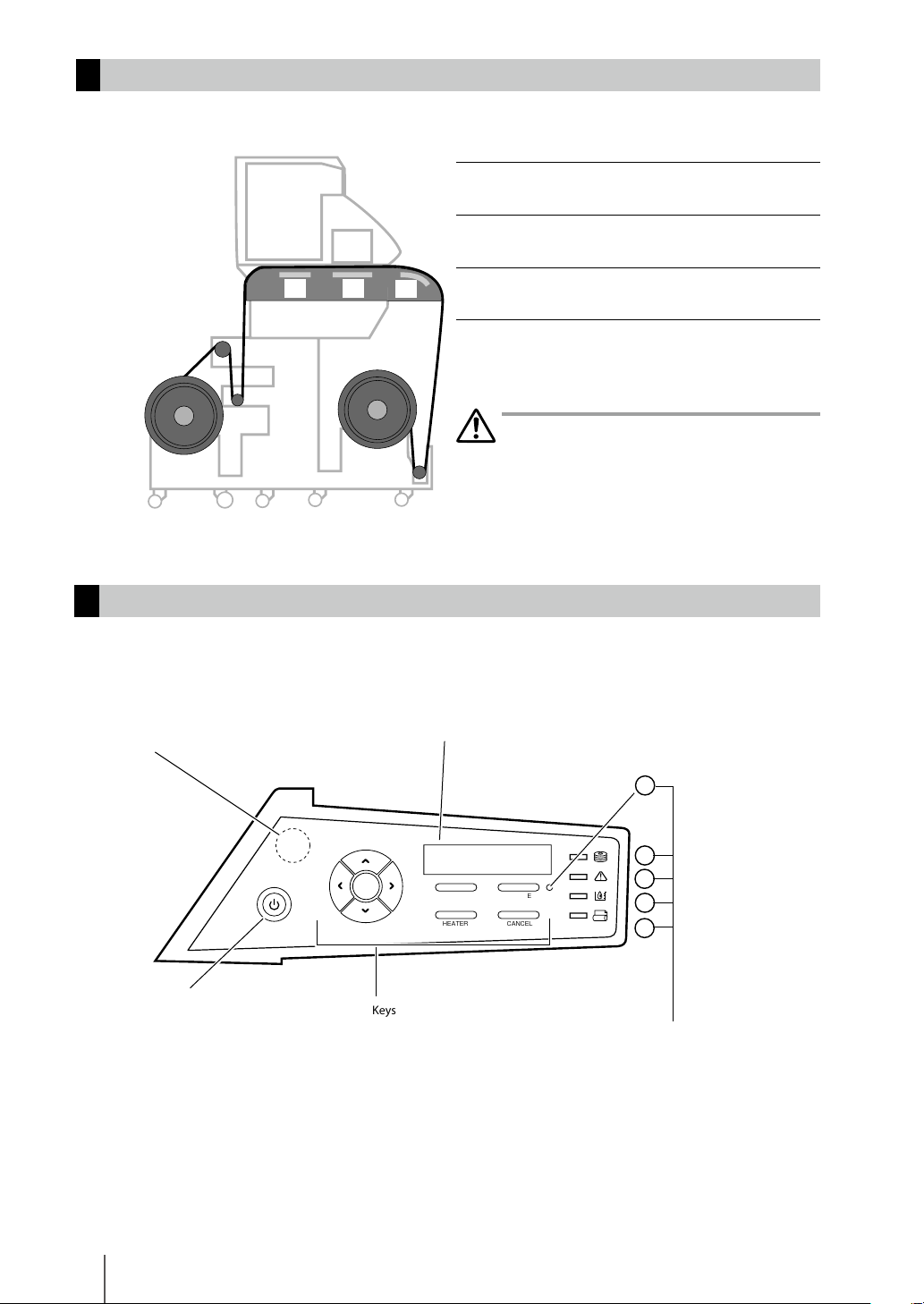

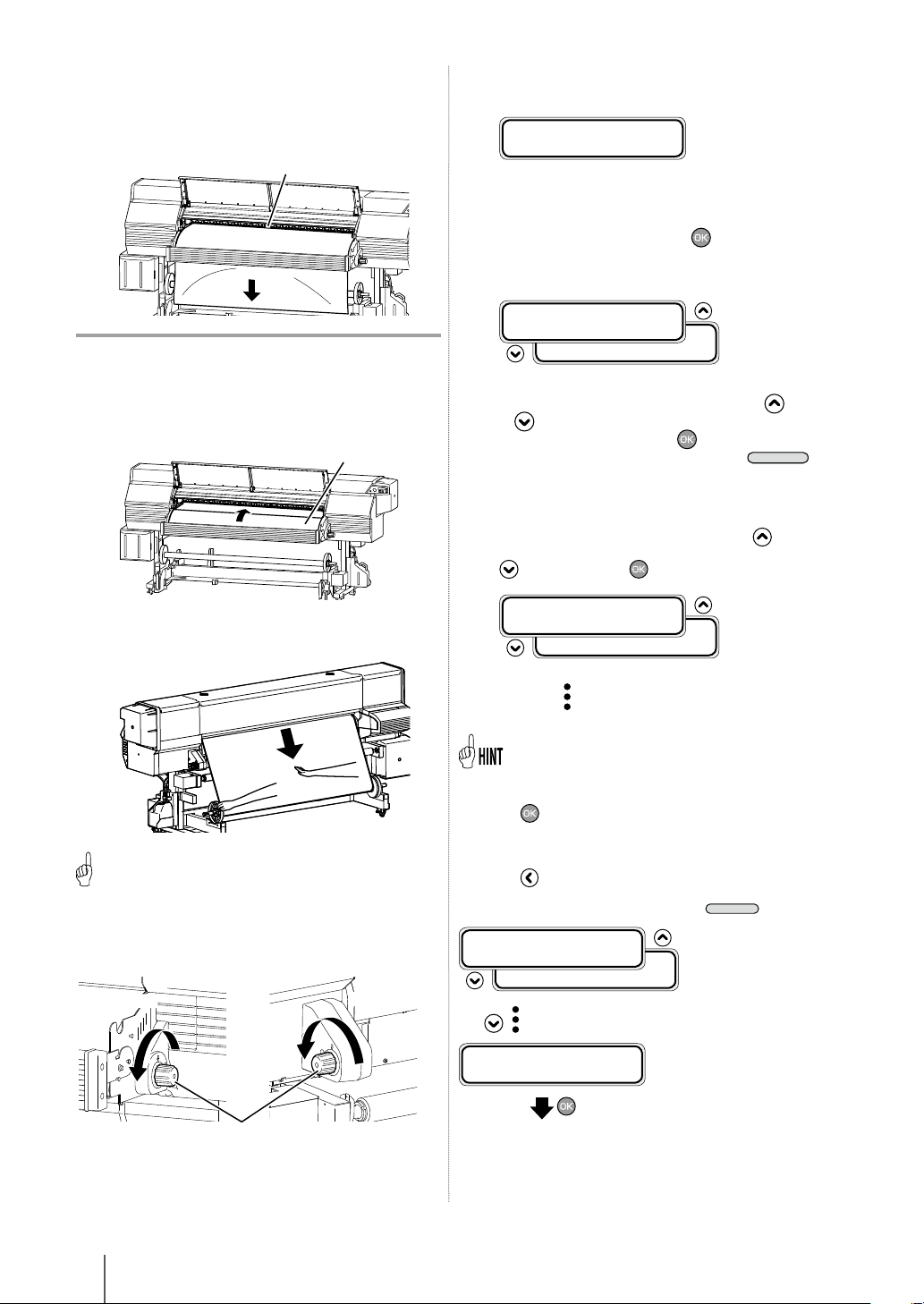

Feed the media until the media end almost

reaches the oor.

In this state, smooth out the media toward the both

sides on the platen to make the media center tense.

Platen

Note

-If the media is set with a distortion or wrinkles, this may cause a

media jam or skew.

12

Feed back the media to the top of the front

paper guide. Front paper guide

Feed back the media while pressing the center of

the media gently at the supply side.

NOTICE

-Step 12 is important to set the media properly.

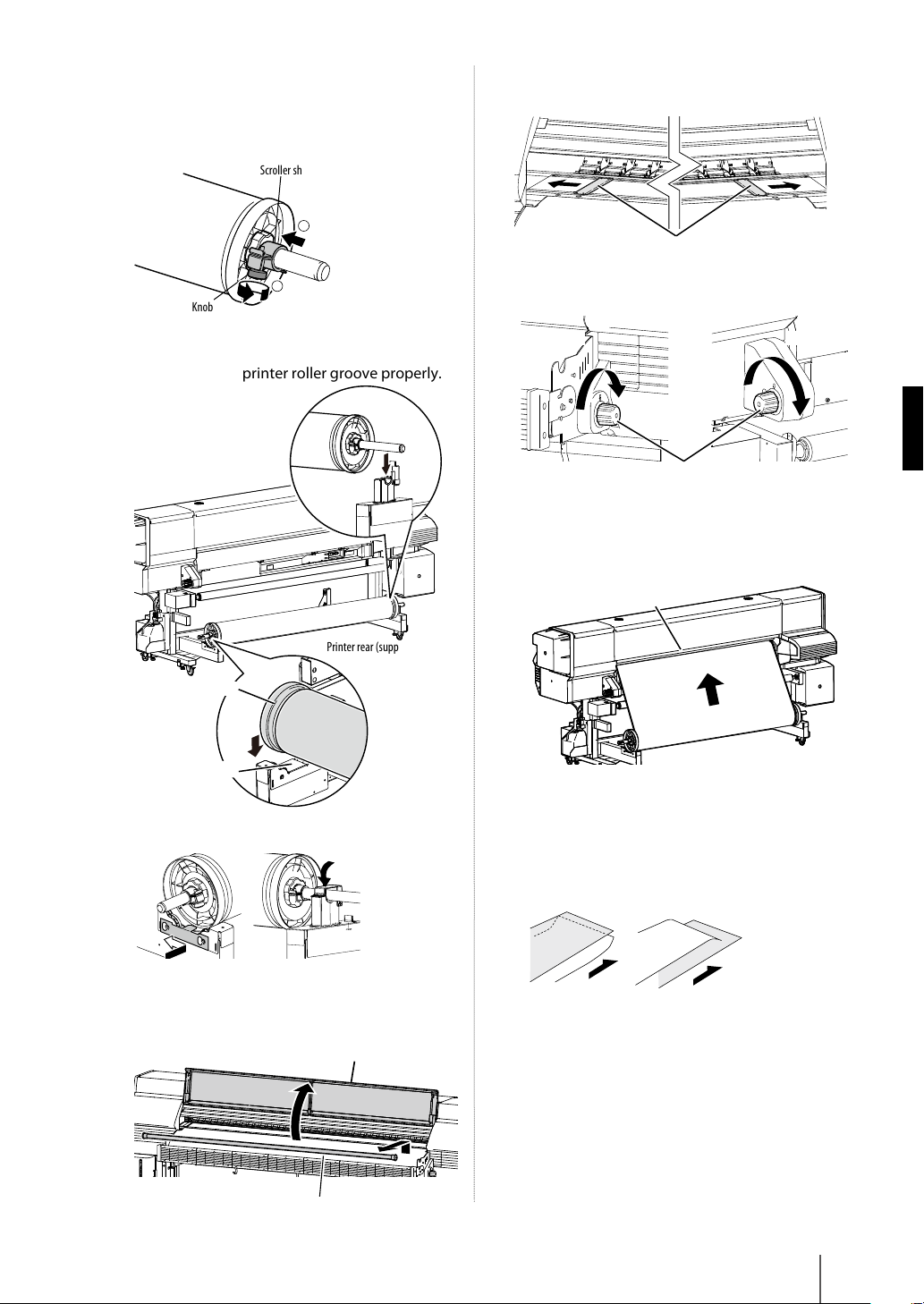

13

Takeup side Supply side

or

Pressure control knobs

Rotate the pressure control knob in the arrow

direction to lower the pressure roller.

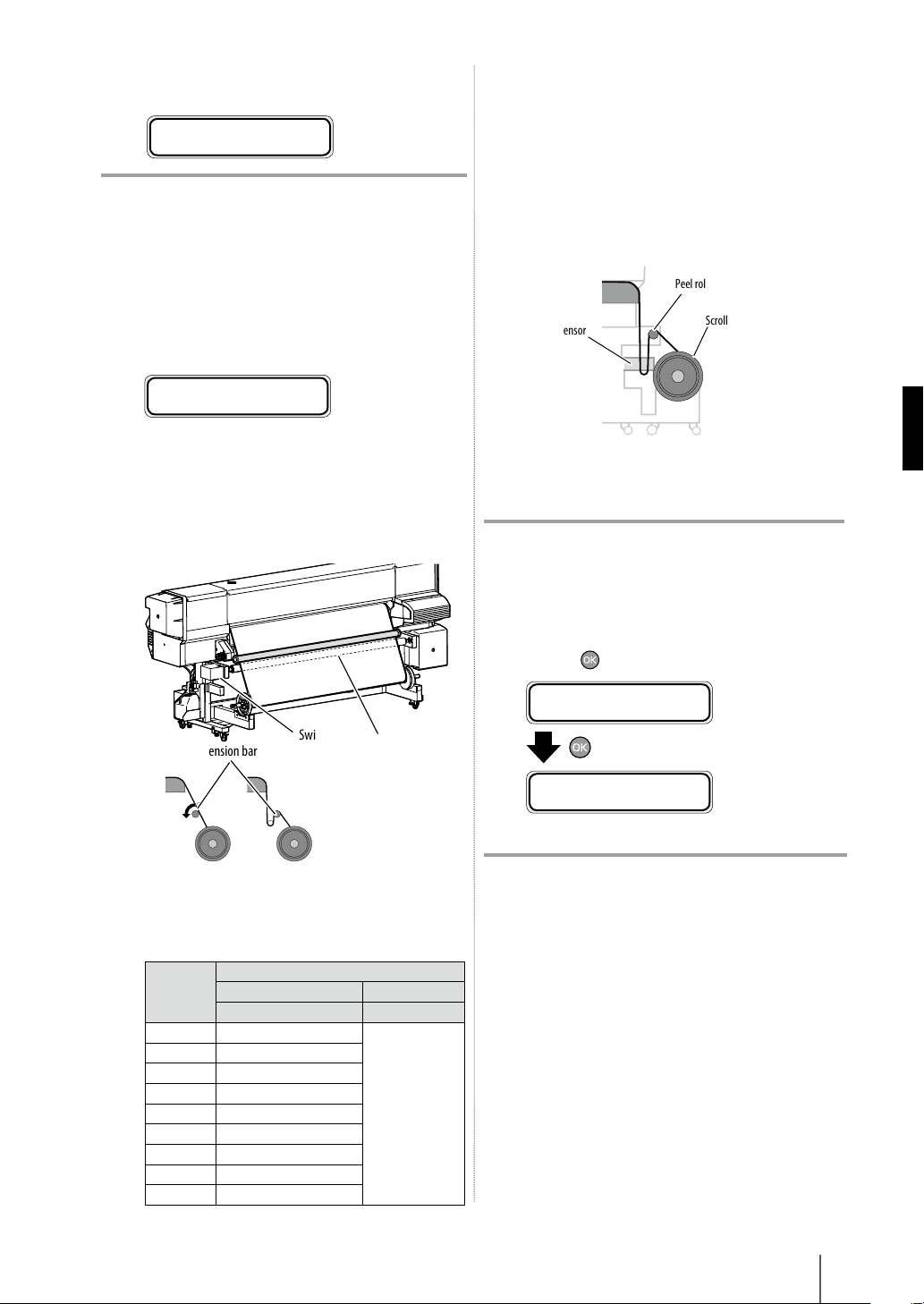

14

Set the media edge guards and close the front

cover.

CHECK EDGE GUARD

*OK?

Check that the media edge guards are not under the

media or thick media is not caught by inserting it

forcibly. After conrming visually that the media edge

guards are properly set, press the key.

15

Select roll media or cut-sheet media.

ROLL/SHEET:SHEET

SELECT MEDIA

ROLL/SHEET:ROLL

Either [roll] or [sheet] can be selected with the key

or key.

Here, select [roll] and press the key.

(To return to the media selection, press the

key.)

16

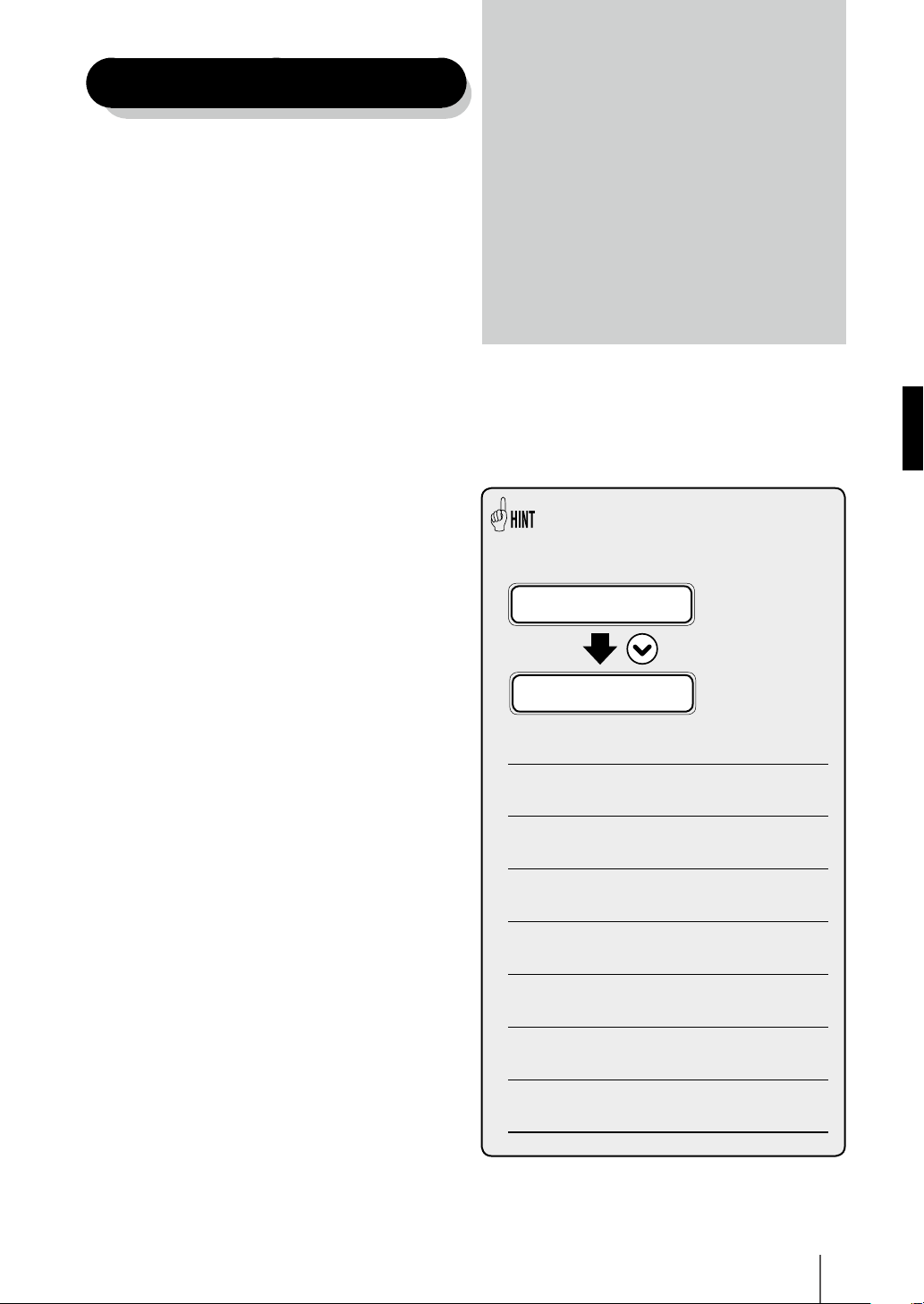

Select the type of media.

Select the registered type of media with the and

keys and press the key.

MEDIA:TYPE02

SELECT MEDIA

MEDIA:TYPE02

To register new media

[NEW MEDIA ENTRY] is displayed at the end of the registered

media.

Press the key to enter MEDIA REG MENU.

The media registration procedure is the same as the registration

from the registration menu.

Press the key to return from the media registration menu to

the media type selection menu.

To return to the value before input, press the

key.

MEDIA:TYPE02

SELECT MEDIA

MEDIA:TYPE02

(The registered media is displayed.)

SELECT MEDIA

NEW MEDIA ENTRY

(Enter the media registration menu.)