42089201TH Rev.4 4 /

Oki Data CONFIDENTIAL

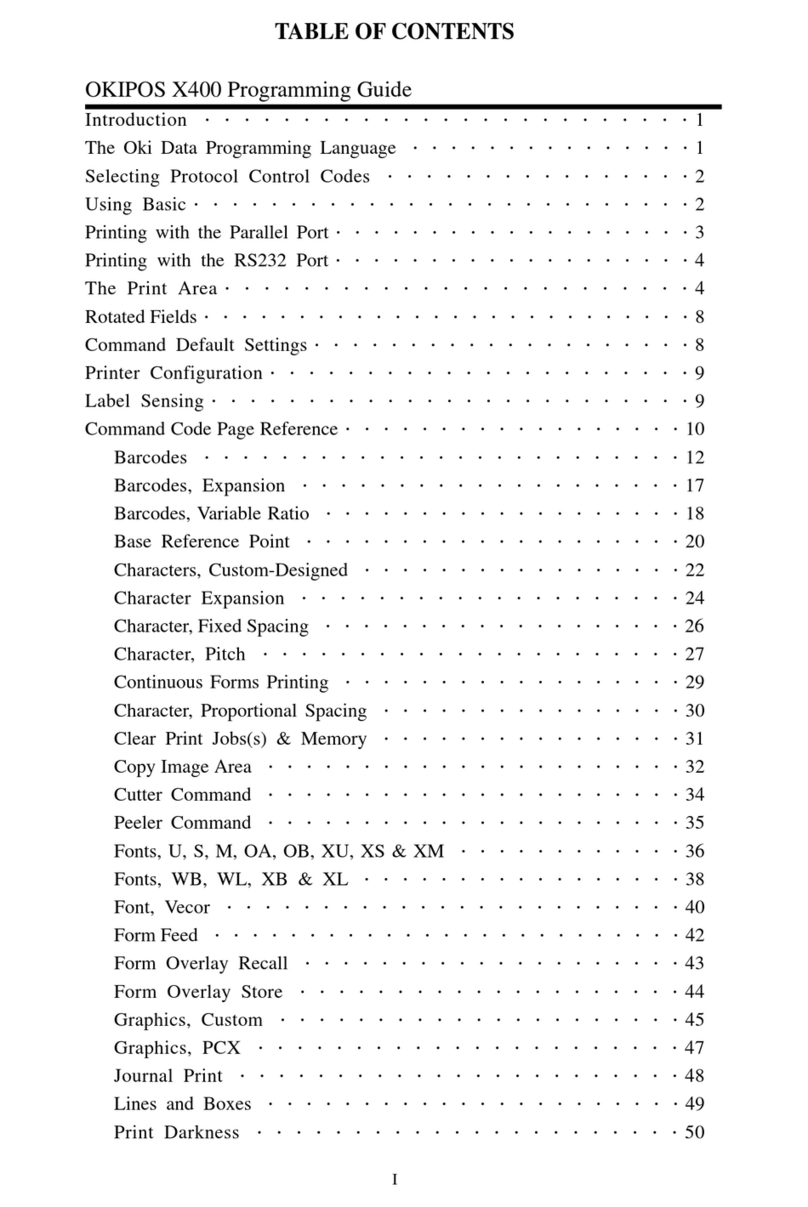

CONTENTS

1. CONFIGURATION ...........................................................................................6

1.1. Standard Printer Configuration ..................................................................................... 6

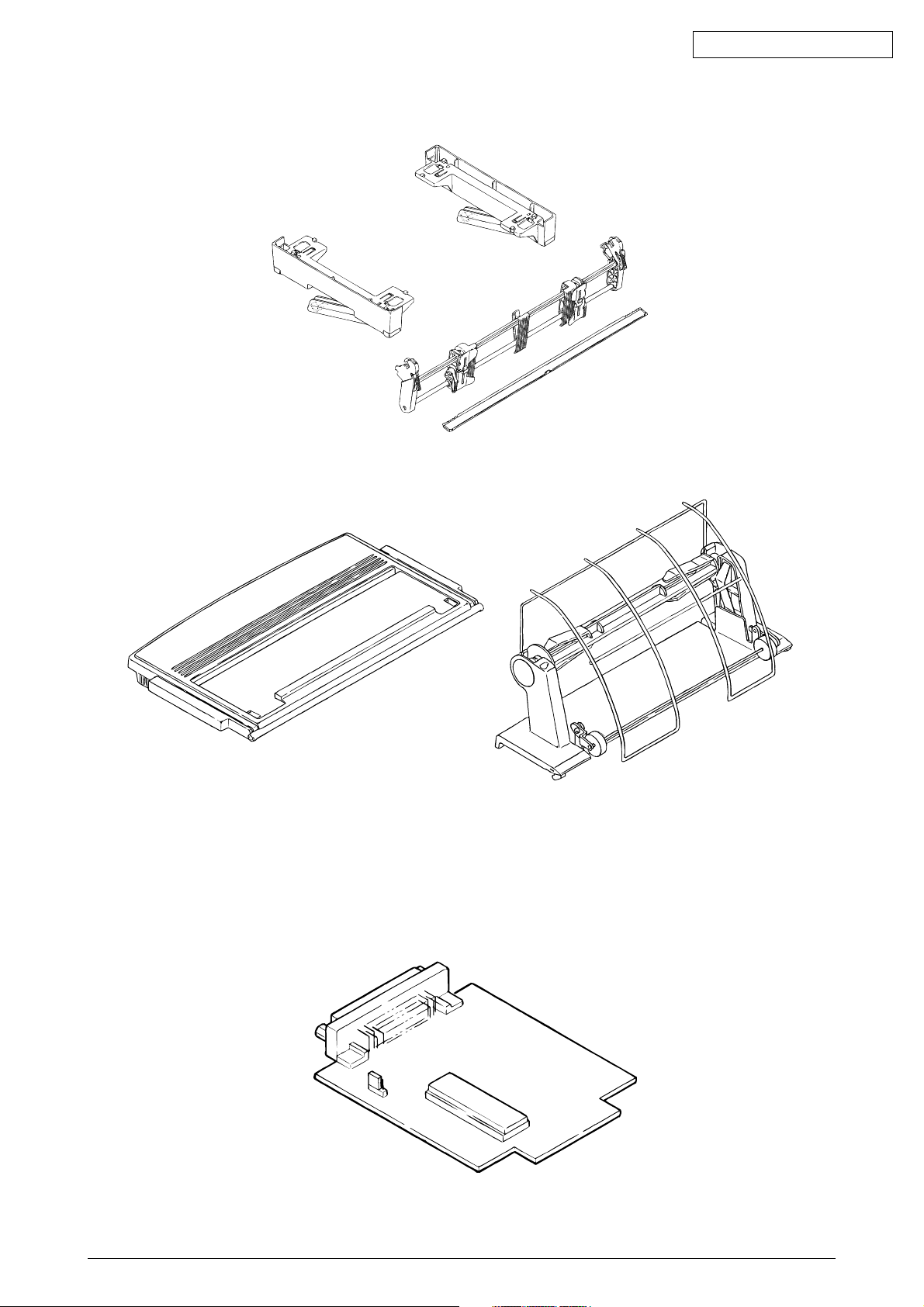

1.2 Options .......................................................................................................................... 7

2. THEORY OF OPERATION .............................................................................9

2.1 Electrical Operation ....................................................................................................... 9

2.1.1 Summary .......................................................................................................... 9

2.1.2 Microprocessor and the Peripheral Circuit ..................................................... 9

2.1.3 Initialization..................................................................................................... 15

2.1.4 Parallel Interface Control ............................................................................... 16

2.1.5 Universal Serial Bus (USB) (at USB Ver.) ................................................... 17

2.1.6 Print Control ................................................................................................... 19

2.1.7 SP/LF Motor Control...................................................................................... 21

2.1.8 Operation Panel ............................................................................................. 23

2.1.9 Alarm Circuit .................................................................................................. 25

2.1.10 Power Supply Circuit ..................................................................................... 27

2.2 Mechanical Operation ................................................................................................. 28

2.2.1 Printhead Mechanism and Operation (See Figure 2-2.).............................. 28

2.2.2 Spacing Operation (See Figure 2-4.) ........................................................... 31

2.2.3 Head Gap Adjusting (See Figure 2-5.)......................................................... 32

2.2.4 Ribbon Drive (See Figure 2-6.) .................................................................... 34

2.2.5 Paper Feed Operation ................................................................................... 35

2.2.6 Paper Detection Mechanism (See Figure 2-15.).......................................... 45

2.2.7 Automatic Sheet Feed ................................................................................... 47

2.2.8 Paper Park Function (Continuous paper) ..................................................... 49

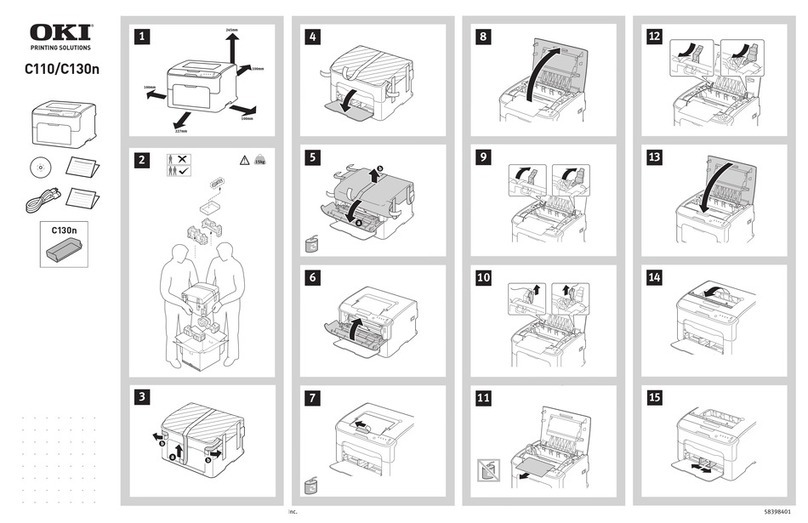

3. ASSEMBLY/DISASSEMBLY.........................................................................50

3.1 Precaution for Parts Replacement ............................................................................. 50

3.2 Service Tools .............................................................................................................. 51

3.3 Disassembly/Reassembly Procedure ......................................................................... 52

3.3.1 Printhead ........................................................................................................ 54

3.3.2 Ribbon Protector ............................................................................................ 55

3.3.3 Pull-up Roller Assy ........................................................................................ 56

3.3.4 Upper Cover Assy, Access Cover Assy and Sheet Guide Assy ................ 57

3.3.5 Gear Case Assy ............................................................................................ 58

3.3.6 PC Connector ................................................................................................ 59

3.3.7 Space Motor, Guide Roller Assy .................................................................. 60

3.3.8 Space Rack.................................................................................................... 61

3.3.9 Carriage Cable ............................................................................................... 62

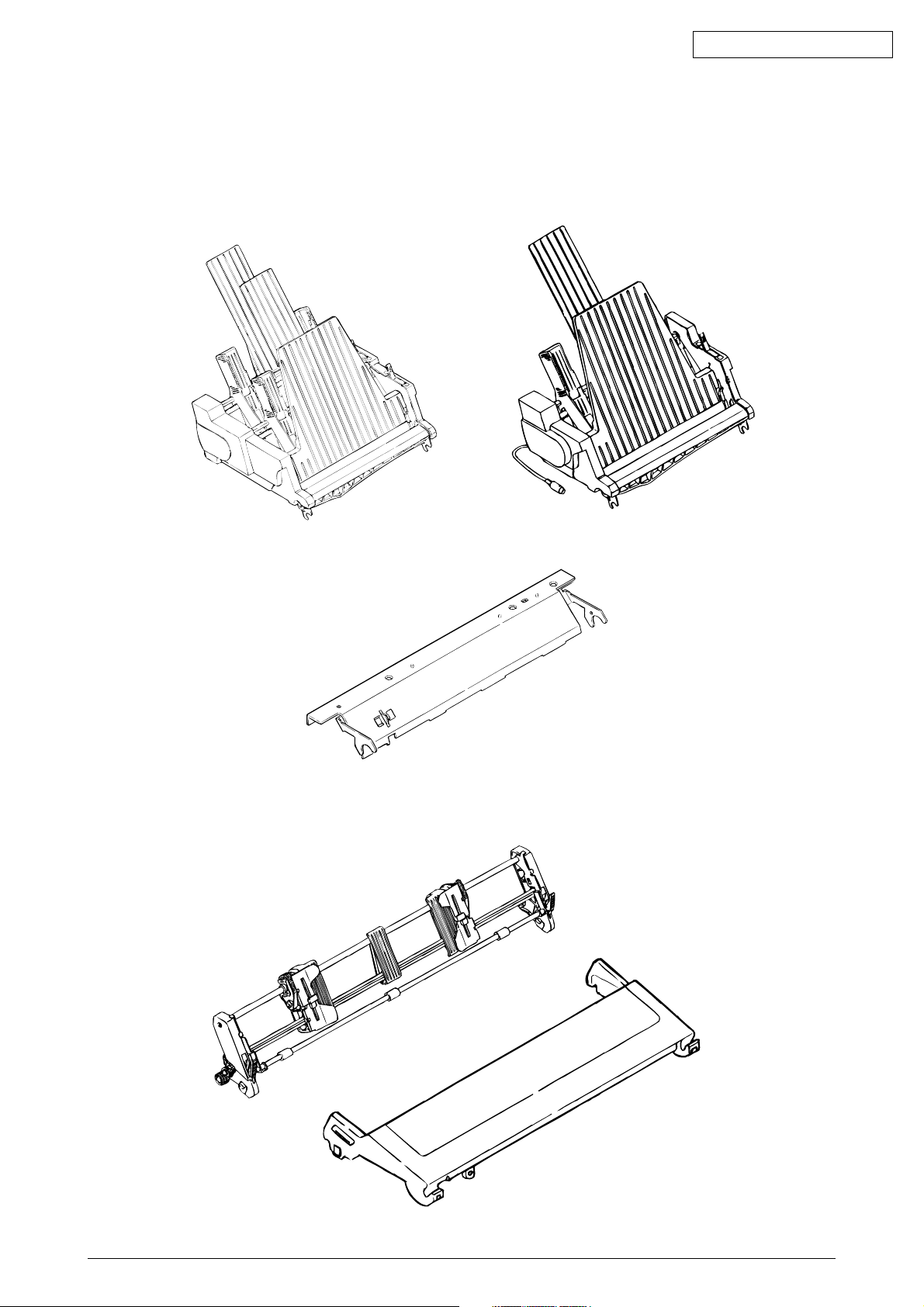

3.3.10 Backup Roller Holder Assy ........................................................................... 63

3.3.11 Platen Assy .................................................................................................... 64

3.3.12.1Driver Board (DVE/DVF) (at USB Ver.) ....................................................... 65

3.3.12.2Driver Board (SDF) (at non USB Ver.) ........................................................ 66

3.3.13 LF Motor......................................................................................................... 67

3.3.14 Operation Panel PCB (LEOP)....................................................................... 68

3.3.15 Control/Power Supply Board (AOE/AOU/AOO) ............................................ 69

3.3.16 Transformer Assy........................................................................................... 70

3.3.17 Change Lever and Gears.............................................................................. 71

3.3.18 Carriage Shaft ................................................................................................ 72

3.3.19 Paper Pan ...................................................................................................... 73

3.3.20 Rear Tractor Assy ......................................................................................... 74