CONTENTS

1. CONFIGURATION..................................................................................... 1 - 1

1.1 System Configuration ........................................................................ 1 - 1

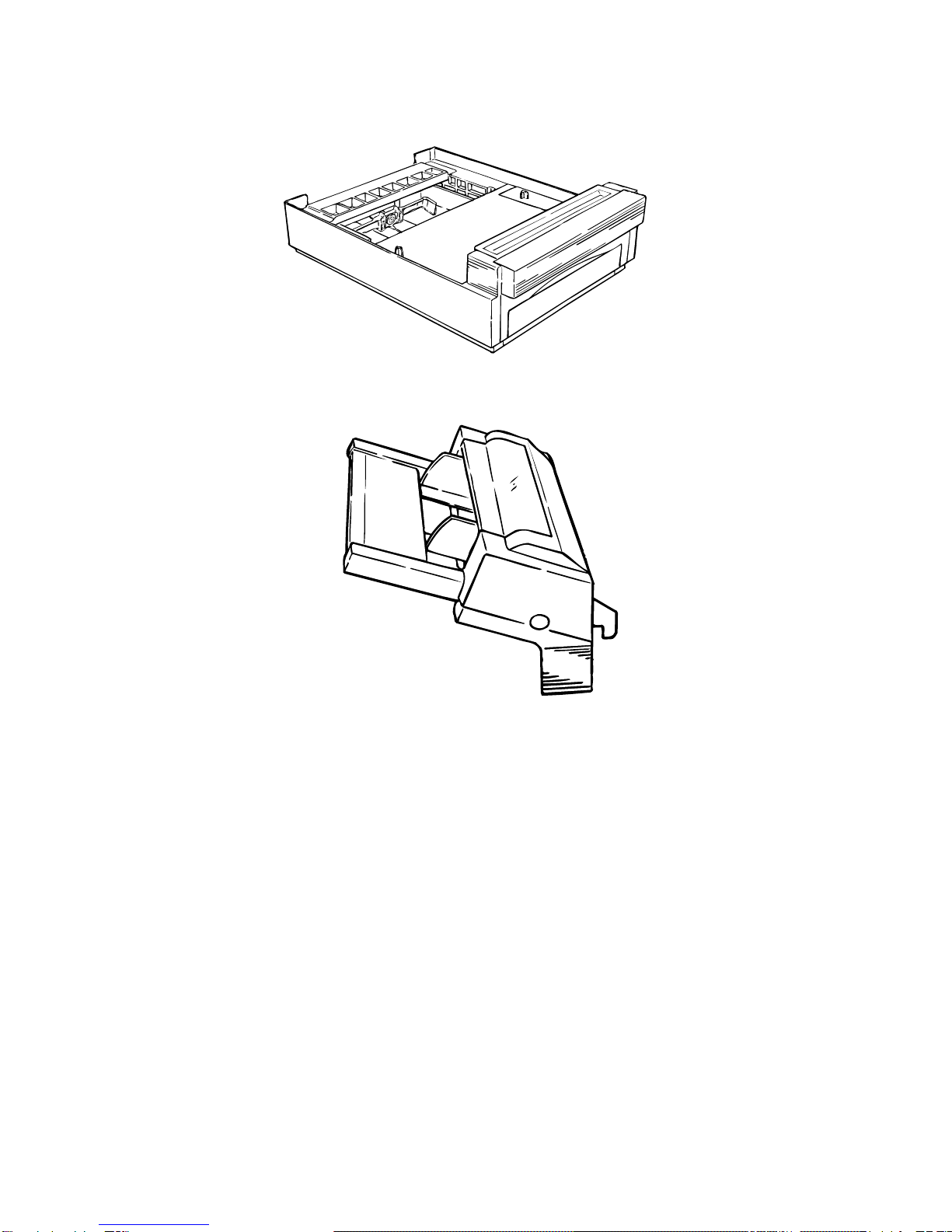

1.2 Printer Configuration.......................................................................... 1 - 2

1.3 Optional Configuration....................................................................... 1 - 3

1.4 Specification ...................................................................................... 1 - 5

1.5 Safety Standards ............................................................................... 1 - 7

1.5.1 Certification Label.................................................................................... 1 - 7

1.5.2 Warning Label .........................................................................................1 - 8

1.5.3 Warning/Caution Marking ........................................................................ 1 - 9

2. OPERATION DESCRIPTION .................................................................... 2 - 1

2.1 Control Board..................................................................................... 2 - 4

2.2 PS Board ........................................................................................... 2 - 6

2.3 RAM Board ........................................................................................ 2 - 7

2.4 Power Supply Board.......................................................................... 2 - 8

2.5 Electrophotographic Process............................................................. 2 - 10

2.5.1 Electrophotographic Process Mechanism ............................................... 2 - 10

2.5.2 Electrophotographic Process .................................................................. 2 - 13

2.5.3 Process Operation Descriptions .............................................................. 2 - 16

2.6 Paper Jam Detection ......................................................................... 2 - 27

2.7 Cover Open ....................................................................................... 2 - 30

2.8 Toner Low Detection.......................................................................... 2 - 31

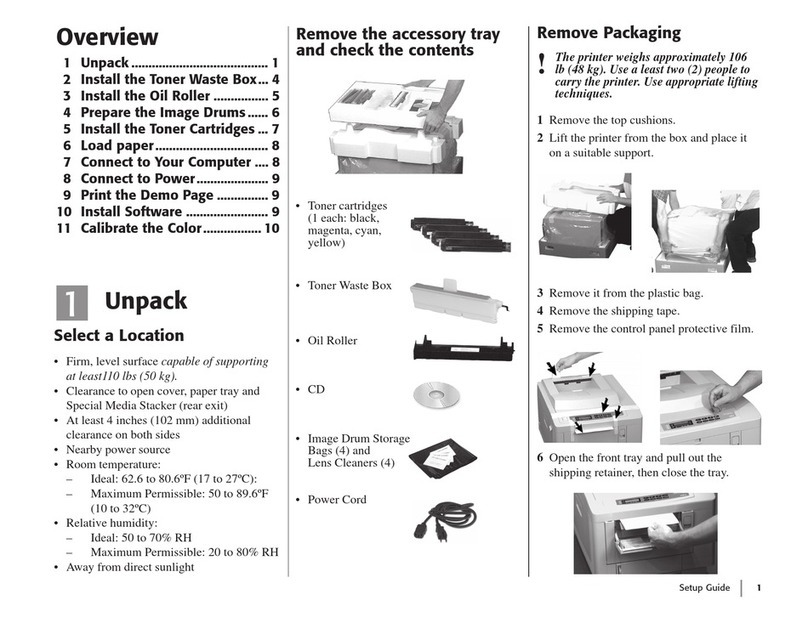

3. PARTS REPLACEMENT........................................................................... 3 - 1

3.1 Precautions for Parts Replacement................................................... 3 - 1

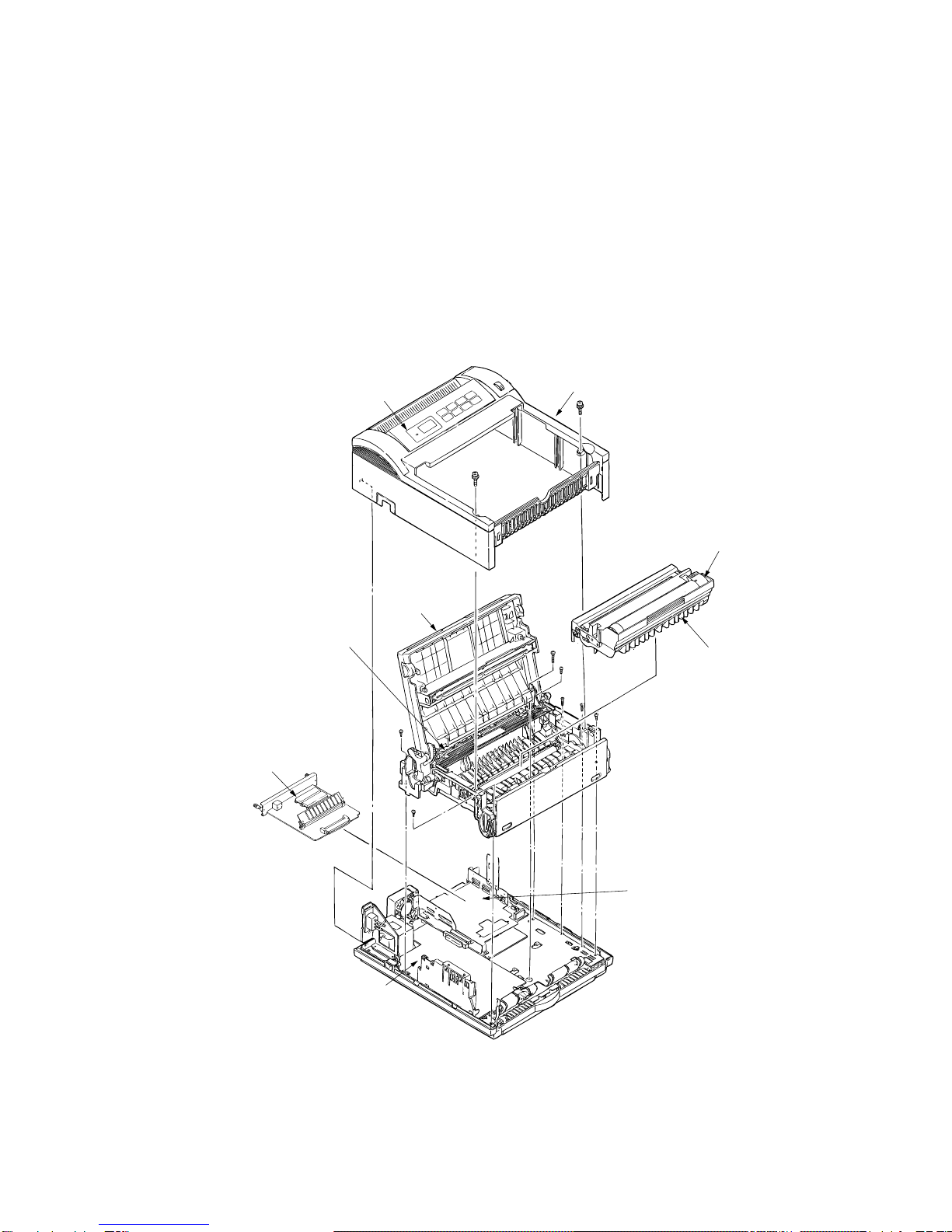

3.2 Parts Layout....................................................................................... 3 - 3

3.3 How to Change Parts......................................................................... 3 - 6

3.3.1 Upper Cover ............................................................................................ 3 - 7

3.3.2 Stacker ....................................................................................................3 - 8

3.3.3 LED Head ................................................................................................ 3 - 9

3.3.4 Eject Roller Assy ..................................................................................... 3 - 10

3.3.5 Pulse Motor (Main) .................................................................................. 3 - 11

3.3.6 Pulse Motor (Registration)....................................................................... 3 - 12

3.3.7 Lower Base Unit ...................................................................................... 3 - 13

3.3.8 Motor Assy ..............................................................................................3 - 14

3.3.9 Hopping Roller Assy ................................................................................3 - 15

3.3.10 Stacker Cover Assy ................................................................................. 3 - 16

3.3.11 Registration Roller ................................................................................... 3 - 17

3.3.12 Transfer Roller.........................................................................................3 - 18

3.3.13 Fusing Unit Assy .....................................................................................3 - 19

3.3.14 Back-up Roller .........................................................................................3 - 20

3.3.15 Sensor Plate (Inlet)..................................................................................3 - 21

3.3.16 Toner Sensor (Adhesion) ........................................................................ 3 - 22

3.3.17 Sensor Plate (Outlet) ............................................................................... 3 - 23

3.3.18 Manual Feed Guide Assy ........................................................................ 3 - 24

3.3.19 Sensor Plate (Paper Supply) ................................................................... 3 - 25

3.3.20 Main Control PCB.................................................................................... 3 - 26

3.3.21 Power Supply Board and Contact Assy .................................................. 3 - 27