Photoelectric Sensors Technical Guide

●Design

Power Reset Time

The Sensor will be ready to detect within approximately 100 ms after

the power is turned ON.

If the Sensor and the load are connected to separate power supplies,

turn ON the Sensor power before turning ON the load power. Any

exceptions to this rule are indicated in Safety Precautions in individual

product information.

Turning OFF Power

An output pulse may be generated when the power is turned OFF. It

is recommended that the load or load line power be turned OFF

before the Sensor power is turned OFF.

Power Supply Types

An unsmoothed full-wave or half-wave rectifying power supply cannot

be used.

Mutual Interference

Mutual interference is a state where an output is unstable because the Sensors are affected by light from the adjacent Sensors.

The following measures can be taken to avoid mutual interference.

Precautions for Correct Use

Counter-

measure Concept Through-beam Sensors Reflective Sensors

1

Use a Sensor

with the

interference

prevention

function.

If Sensors are mounted in close proximity, use Sensors with the interference prevention function.

10 or fewer Sensors: E3X-DA@-S, E3X-MDA, E3C-LDA Fiber Sensors

Performance, however, will depend on conditions. Refer to pages E3X-DA-S/E3X-MDA

and E3C-LDA.

5 or fewer Sensors: E3X-NA Fiber Sensors

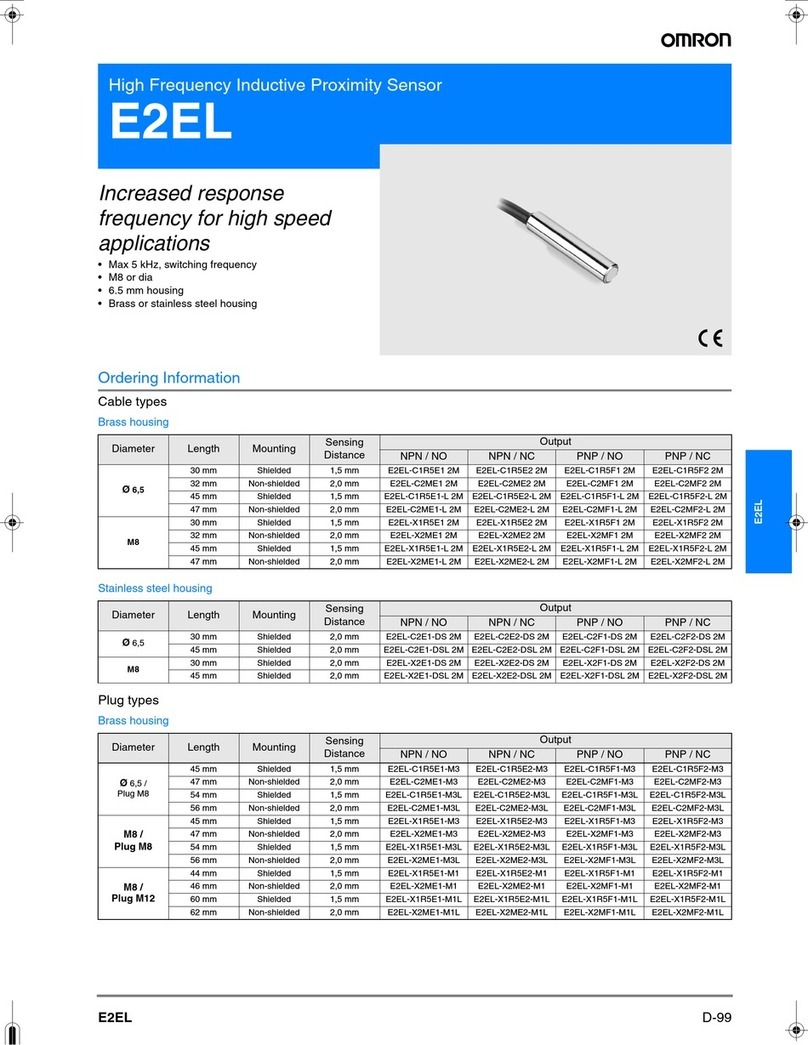

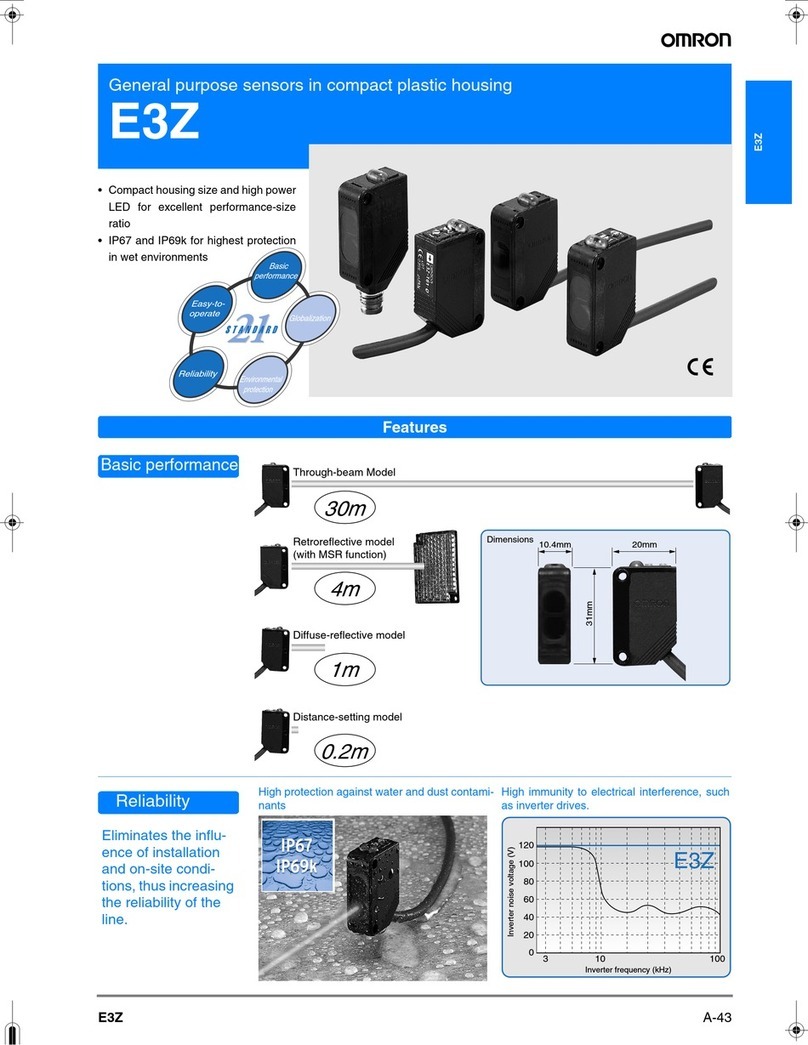

2 or fewer Sensors: E3T, E3Z, E3ZM, E3ZM-C, E3S-C, E3G-L1/L3, or E3S-C Built-in Amplifier Photoelectric

Sensors (except Through-beam Sensors)

E3C Photoelectric Sensor with separate amplifier

2

Install an

inference

prevention

filter.

A mutual interference prevention polarizing filter can be

installed on only the E3Z-TA to allow close-proximity

mounting of up to 2 Sensors.

Mutual Interference Prevention Polarizing Filter: E39-E11

---

3

Separate

Sensors to

distance where

interference

does not occur.

Check the parallel movement distance range in the

catalog, verify the set distance between adjacent

Sensors, and install the Sensors accordingly at a

distance at least 1.5 times the parallel movement

distance range.

If the workpieces move from far to near, chattering may

occur in the vicinity of the operating point. For this type of

application, separate the Sensors by at least 1.5 times the

operating range.

4

Alternate

Emitters and

Receivers.

Close mounting of Sensors is possible by alternating

the Emitters with the Receivers in a zigzag fashion (up

to two Sensors). However, if the workpieces are close

to the Photoelectric Sensors, light from the adjacent

Emitter may be received and cause the Sensor to

change to the incident light state.

---

5

Offset the

optical axes.

If there is a possibility that light from another Sensor

may enter the Receiver, change the position of the

Emitter and Receiver, place a light barrier between the

Sensors, or take other measures to prevent the light

from entering the Receiver.

(Light may enter even if the Sensors are separated by

more than the sensing distance.)

If Sensors are mounted in opposite each other, slant the

Sensors as shown in the following diagram. (This is

because the Sensors may affect each other and cause

output chattering even if separated by more than the

Sensor sensing distance.)

6Adjust the

sensitivity.

Lowering the sensitivity will generally help.

L

1.5 ×L

Sensor Sensor

Workpiece

Workpiece

Emitter

Receiver

Receiver

Emitter

Workpiece

Sensor Sensor

θθ

http://www.ia.omron.com/ C-2

(c)Copyright OMRON Corporation 2007 All Rights Reserved.