E5CSL/E5CWL/E5EWL

9

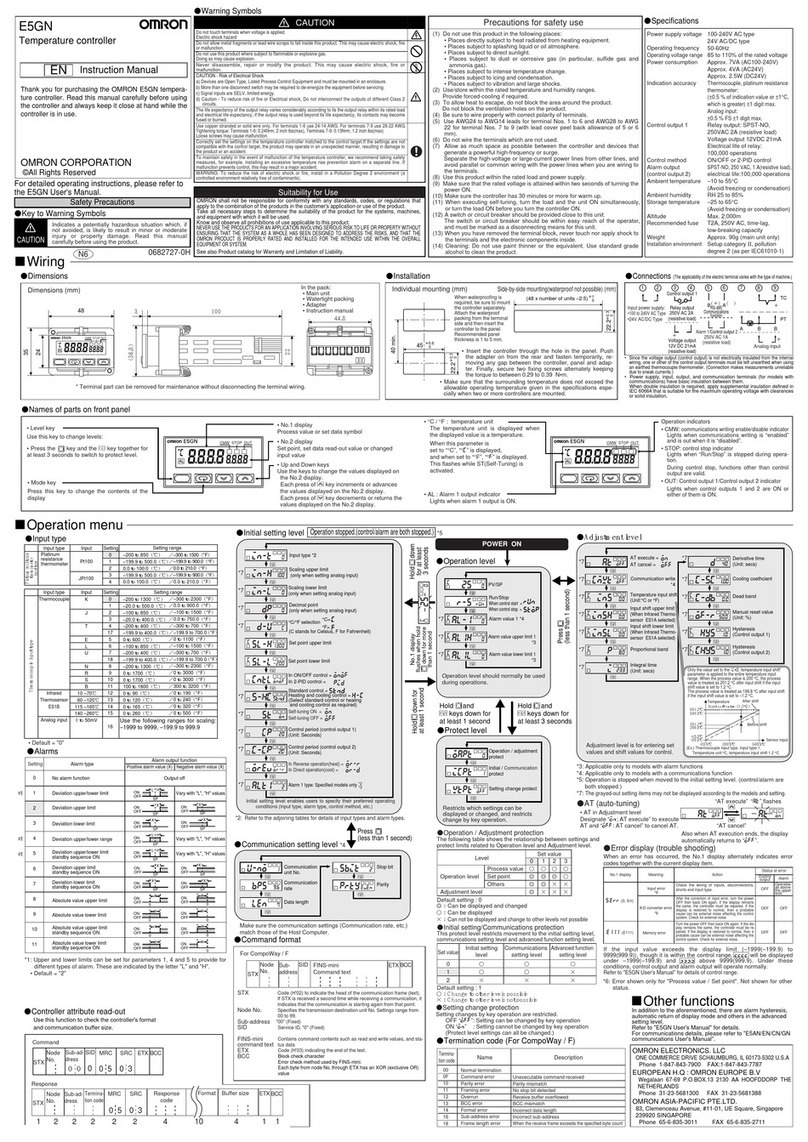

Safety Precautions

Precautions for Safe Use

Be sure to observe the following precautions to prevent operation

failure, malfunction, or adverse affects on the performance and

functions of the product. Not doing so may occasionally result in

unexpected events.

1. The product is designed for indoor use only. Do not use the

product outdoors or in any of the following locations.

Places directly subject to heat radiated from heating equipment.

Places subject to splashing liquid or oil atmosphere.

Places subject to direct sunlight.

Places subject to dust or corrosive gas (in particular, sulfide gas

and ammonia gas).

Places subject to intense temperature change.

Places subject to icing and condensation.

Places subject to vibration and large shocks.

2. Use/store within the rated temperature and humidity ranges.

Provide forced-cooling if required.

3. To allow heat to escape, do not block the area around the product.

Do not block the ventilation holes on the product.

4. Be sure to wire properly with correct polarity of terminals.

5. Use specified size (M3.5, width 7.2 mm or less) crimped terminals

for wiring. To connect bare wires to the terminal block, use copper

braided or solid wires with a rated temperature of over 70C and a

gauge of AWG24 to AWG14 (equal to a cross-sectional area of

0.205 to 2.081 mm2). (The stripping length is 5 to 6 mm.) Up to two

wires of same size and type, or two crimped terminals can be

inserted into a single terminal.

6. Do not wire the terminals which are not used.

7. Allow as much space as possible between the controller and

devices that generate a powerful high-frequency or surge.

Separate the high-voltage or large-current power lines from other

lines, and avoid parallel or common wiring with the power lines

when you are wiring to the terminals.

8. Use this product within the rated load and power supply.

9. Make sure that the rated voltage is attained within two seconds of

turning ON the power using a switch or relay contact. If thevoltage

is applied gradually, the power may not be reset or output

malfunctions may occur.

10.Make sure that the Controller has 30 minutes or more to warm up

after turning ON the power before starting actual control

operations to ensure the correct temperature display.

11.A switch or circuit breaker should be provided close to this unit.

The switch or circuit breaker should be within easy reach of the

operator, and must be marked as a disconnecting means for this

unit.

12.Do not use paint thinner or similar chemical to clean with. Use

standard grade alcohol.

13.Design system (control panel, etc) considering the 2 seconds of

delay that the controller’s output to be set after power ON.

14.The output may turn OFF when shifting to certain levels. Take this

into consideration when performing control.

15.The number of non-volatile memory write operations is limited.

Do not touch the terminals while power is being

supplied.

Doing so may occasionally result in minor injury due to

electric shock.

Do not allow pieces of metal, wire clippings, or fine

metallic shavings or filings from installation to enter the

product. Doing so may occasionally result in electric

shock, fire, or malfunction.

Do not use the product where subject to flammable or

explosive gas. Otherwise, minor injury from explosion

may occasionally occur.

Never disassemble, modify, or repair the product or

touch any of the internal parts. Minor electric shock, fire,

or malfunction may occasionally occur.

If the output relays are used past their life expectancy,

contact fusing or burning may occasionally occur.

Always consider the application conditions and use the

output relays within their rated load and electrical life

expectancy.

The life expectancy of output relays varies considerably

with the output load and switching conditions.

Tighten the terminal screws to between 0.74 and 0.90

N·m. Loose screws may occasionally result in fire.

Set the parameters of the product so that they are

suitable for the system being controlled. If they are not

suitable, unexpected operation may occasionally result

in property damage or accidents.

A malfunction in the Temperature Controller may

occasionally make control operations impossible or

prevent alarm outputs, resulting in property damage. To

maintain safety in the event of malfunction of the

Temperature Controller, take appropriate safety

measures, such as installing a monitoring device on a

separate line.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.