Note: Specifications subject to change without notice.

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69,2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300

Fax: (31)2356-81-388

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road #05-05/08

(Lobby 2), Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011

Fax: (65) 6835-2711

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900

Fax: (1) 847-843-7787

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

Pu Dong New Area, Shanghai,

200120, China

Tel: (86) 21-5037-2222

Fax: (86) 21-5037-2200

OMRON Corporation Industrial Automation Company

Contact: www.ia.omron.com

Kyoto, JAPAN

*1 The set values for the time range are as follows:

I/O Functions

Input Connections

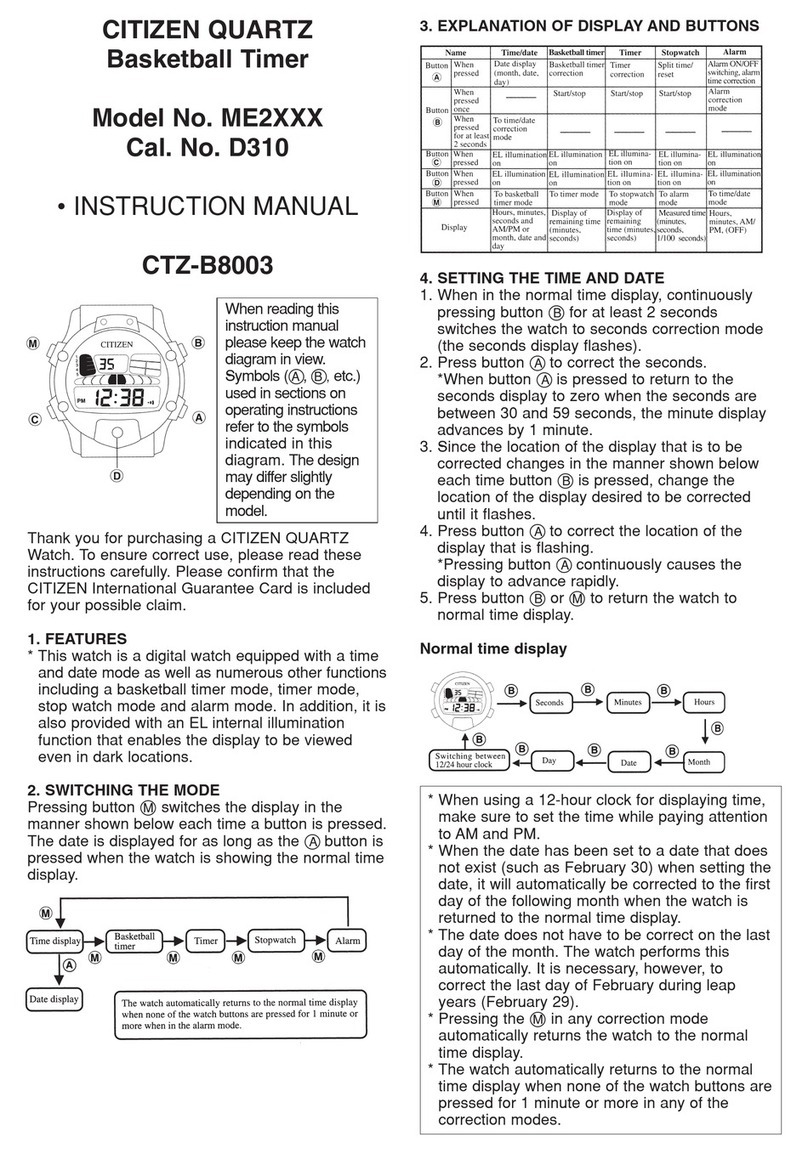

Panel-cutout Dimensions

Diagram (Unit: mm)

Standard panel cutout is shown in the following

diagram. (conforms to DIN 43700)

A space of 15 mm or greater (a panel cut-out

distance of 60 mm or greater) is recommended

towards the Adapter's hook side to enable easier

mounting work.

1. The thickness of a mounting panel should be

1 to 5 mm.

2. It is possible to mount Timers side-by-side.

(But only towards the non-hook side.)

Mounting and Panel-cutout Dimensions Diagram

Mounting Dimensions (Unit: mm)

Front panel dimensions

are the same for all

models.

H5CC-AWSD

3. If the products are mounted side by side,

water resistance will be lost.

Ratings (Specifications)

Nomenclature

Operating Procedures

Terminal Arrangement

Output Mode

Change from RUN Mode to Function Setting Mode.

Set the parameters using the UP Key or DOWN Key.

The characters displayed in reverse video are the default settings.

Press UP1+UP3 keys once to move to the previous parameter.

Press DW1+DW3 keys once to move to the next parameter.

Operation in Function Setting Mode

Note: Refer to the datasheet for detailed parameter settings.

Operation Key

8. UP Keys (UP1 to UP6) (UP 1, 2, 3, 4, 5 and 6 from right to left)

9. DOWN Keys (DW1 to DW6) (DW 1, 2, 3, 4, 5 and 6 from right to left)

10. Reset operation (UP6+DW6)

1.

Press RST keys (UP6+DW6) simultaneously for at least one second.

2.

LED on each key starts blinking. If not blink, that because the keys are not pressed

simultaneously. In this case, release the keys after pressing for at least 1 second,

and restart from 1. Do not release the keys until the LED starts blinking. Otherwise

the setting value may change.

3.

Press and hold until the LED turns off. If you release the keys while blinking, the

reset operation will be interrupted.

11. Mode operation (UP1+UP3 or DW1+DW3)

<Change of setting item>

1.

Press MODE keys (UP1+UP3 or DW1+DW3) simultaneously to switch setting items.

<Move to Function Setting Mode>

1.

Press MODE key (UP1+UP3 or DW1+DW3) for at least 2 seconds simultaneously.

2.

LEDs on UP1 (DW1) and UP3 (DW3) key start blinking. If not blink, that because the

keys are not pressed simultaneously. In this case, release the keys after pressing

for at least one second, and restart from 1. Do not release the keys until the LEDs

start blinking. Otherwise the setting value may change.

3.

Press and hold until the LED turns off. If you release the keys during blinking, the

mode will not be moved to Function Setting Mode.

12. Status indicator

<When Run mode is selected.>

• When the indicator display mode is on, the LED indicator shows the percentage of

the present value from 0 to 100%.

• When the indicator display mode is all off or all lit, the LEDs are all off or all lit.

Note: When you press the UP key or the DOWN key, the indicator display or all-lit

display goes off, and the LED indicator of the pressed key lights up or blinks.

<When Function Setting Mode is selected>

• The LED indicators at the settable key positions will light.

timr

pl-h

sl-h

setn

imod

iflt

outm

Time range

Output mode

Forecast setting upper limits

Set value upper limit

Absolute value setting/ forecast

value setting

NPN/PNP input mode

Input signal width

---

---

---

---

---

---

*1

1~999999

1~999999

ofst, abs

npn, pnp

20ms, 1ms

a, f-1

ot1i

ver

ot-c

ot-a

on2c

on1c

on2a

on1a

indc

ot2i

Output 1 inversion

Software version

Total run time monitor value

Total run time alarm set value

Output 2 (OUT2) ON count

monitor value

Output 1 (OUT1) ON count

monitor value

Output 2 (OUT2) ON count alarm

set value

Output 1 (OUT1) ON count alarm

set value

Indicator display mode

Output 2 inversion

---

---

---

×1,000

×1,000

The software version is only displayed. It cannot be set.

The Total run time monitor value is only displayed.

It cannot be set.

Unit: yea

The monitor value is only displayed. It cannot be set.

×1,000

The monitor value is only displayed. It cannot be set.

×1,000

n-o, n-c

0.0 ~10.0 ~99.9

---

---

---

---

0~100 ~9999

0~100 ~9999

on, alof, allt

n-o, n-c

kypt Key protect level ---

kp-1, kp-2, kp-3, kp-4,

kp-5, kp-6, kp-7

Display Parameter name

Comments

Set value

Operation in Run Mode

Operation in Run Mode

Basic Operation

Basic Operation

Forecast Value Setting

Absolute Value Setting

• The control output (output 2) turns ON when the present value reaches the set value.

• Forecast output (OUT1) turns ON when the present value reaches the forecast value.

The forecast value is the set value minus the forecast set value.

• If the forecast set value ≥ set value, OUT1 (forecast output) will turn ON as soon as timing starts.

• If the set value equals 0, the forecast output (output 1) and control output (output 2) will turn ON as soon as

timing starts.

• OUT1 (control output 1) turns ON when the present value reaches set value 1.

• OUT2 (control output 2) turns ON when the present value reaches set value 2.

• If the set value equals 0, the control output will turn ON as soon as timing starts.

• Starts timing.

Turns ON when the present value reaches

set value 1.

Turns ON when the present value reaches

set value 2.

Turns ON when the present value reaches

the forecast value.

Turns ON when the present value reaches

the set value.

• Inhibits timer operation.

• Resets present value. (The present value

returns to 0.)

• Timing stops and control output turns

OFF while reset input is ON.

•

Reset indicator is lit while reset input is ON.

Control

output 1

(OUT1)

Control

output 2

(OUT2)

Forecast

output

(OUT1)

Control

output

(OUT2)

Forecast

value

setting

Absolute

value

setting

Start signal

Reset

Gate

Inputs

Outputs

The inputs of the Timer are no-voltage (short-circuit or open) inputs or

voltage inputs.

No-voltage Inputs (NPN Inputs)

Voltage Inputs (PNP Inputs)

Open Collector

No-contact Input (NPN Transistor) No-contact Input (PNP Transistor)

Contact input

Voltage Output

Contact Input Two-wire Sensor

Short-circuit level (Transistor ON)

• Residual voltage: 3 V max.

• Impedance when ON: 1 kΩmax.

(The leakage current is approx. 12 mA when the

impedance is 0 Ω.)

No-voltage Input Signal Levels

Open level (Transistor OFF)

• Impedance when OFF: 100 kΩmin.

Use contacts which can adequately switch 10 V, 5 mA

Note 1: The DC voltage must be 30 VDC max.

No-contact

input

Contact input

Leakage current: 1.5 mA max.

Switching capacity: 5 mA min.

Residual voltage: 3.0 V DC max.

Operating voltage: 10 V DC

Applicable Two-wire Sensor

Voltage Input Signal Levels

High level (Input ON): 4.5 to 30 V DC

Low level (Input OFF): 0 to 2 V DC

Note 1: The DC voltage must be 30 V DC max.

Note 2: Input resistance: Approx. 4.7 kΩ

• Confirm that the power supply to the Timer

meets specifications before use.

*Start signal input is disabled during timing.

The names in parentheses are used for the absolute value setting.

The names in parentheses are used for

the absolute value setting.

* Terminals 7 and 10 have the same reset

function. The same function will be

performed whichever terminal is connected.

Terminals 7 and 10 are not connected

internally, so do not use them for cross

wiring.

* • The solid state output is insulated from the

internal circuitry by a photocoupler, so the

solid state output can be used as both NPN

and PNP output.

• The diode connected to

the collector of the

output transistor is used

to absorb inverted

voltage that is

generated when an

inductive load is

connected to the H5CC.

* Each time the UP1+UP3 or

DW1+DW3 Keys are pressed,

the set value display (6) will

switch between the set value

and the forecast set value.

* Each time the UP1+UP3 or

DW1+DW3 Keys are pressed,

the set value display (6) will

switch between set values 1

and 2.

Precautions for Safe Use

SAFETY PRECAUTIONS

Keys to Warning Symbols

Indicates a potentially hazardous situation which, if not

avoided, is likely to result in minor or moderate injury or in

property damage.

Do not disassemble, modify, or repair the Timer or touch internal

components. Minor electric shock, fire, or malfunction may occasionally

occur.

Do not touch any of the terminals while power is being supplied. Be sure to

mount the terminal cover after wiring. Minor injury due to electric shock

may occasionally occur.

Fire may occasionally occur. Tighten the terminal screws to the rated torque.

H5CC terminals and P3GA-11/P3G-08 Socket terminals: 6.55 to 7.97 lb-in

(0.74 to 0.90 N·m)

P2CF Socket terminals: 4.4 lb-in (0.5 N·m)

Do not use the Timer where subject to flammable or explosive gas. Minor

injury due to explosion may occasionally occur.

Do not allow pieces of metal, wire clippings, or fine metallic shavings or

fillings from installation to enter the product. Doing so may occasionally

result in electric shock, fire, or malfunction.

• Locations subject to oil.

• Locations prone to icing.

• Locations subject to exposure chemicals.

• Locations subject to bugs and small animals.

6) Do not use this Timer in dusty environments, in locations where corrosive gasses are

present, or in locations subject to direct sunlight.

7) Install the Timer well away from any sources of static electricity, such as pipes

transporting molding materials, powders, or liquids.

8) Internal elements may be destroyed if a voltage outside the rated voltage range is applied.

9) Be sure that polarity is correct when wiring the terminals.

10) Separate the Timer from sources of noise, such as devices with input signals from power

lines carrying noise, and wiring for I/O signals.

11) Do not connect more than two crimp terminals to the same terminal.

12) Up to two wires of the same size and type can be inserted into a single terminals.

13) Use the specified wires for wiring.

Applicable Wires: AWG 18 to AWG 22, solid or twisted, copper

Wiring stripping length: 5 to 6 mm (recommended)

14) Install a switch or circuit breaker that allows the operator to immediately turn OFF the

power, and label it to clearly indicate its function.

15) When the Timer is operated with no-voltage input (NPN input), approximately 14 V is

output from the input terminals. Use a sensor that contains a diode.

16)

Use a switch, relay, or other contact so that the rated power supply voltage will be reached

within 0.1 second. If the power supply voltage is not reached quickly enough, the Timer may

malfunction or outputs may be unstable. Use a switch, relay, or other contact so that the

rated power supply voltage will be reached within 0.1 second. If the power supply voltage is

not reached quickly enough, the Timer may malfunction or outputs may be unstable.

17) Use a switch, relay, or other contact to turn the power supply OFF instantaneously.

Outputs may malfunction and memory errors may occur if the power supply voltage is

decreased gradually.

18) If the set value is changed as follows during a timing operation, the output will turn ON because

of the use of a constant read-in system:

(1) For forecast value setting

Changing the value so that Present value ≥ Set value turns ON output 2 (control output).

Changing the value so that Present value ≥ Forecast value (The forecast value = set value -

forecast set value) turns ON output 1 (forecast output).

(2) For absolute value setting

Changing the value so that Present value ≥ Set value 2 turns ON output 2 (control output 2).

Changing the value so that Present value ≥ Set value 1 turns ON output 1 (control output 1).

When the set value is 0, the output turns ON the moment the signal is input. The reset

operation turns OFF the output.

19)

Do not use organic solvents (such as paint thinners or benzine), strong alkali, or strong acids.

20) Confirm that indications are working normally, including the backlight LEDs, and LCD. The

indicator LEDs, LCD, and resin parts may deteriorate more quickly depending on the

application environment, preventing normal indications. Periodic inspection and

replacement are required.

21) The waterproof packing may deteriorate, shrink, or harden depending on the application

environment. Periodic inspection and replacement are required.

1) When mounting the Timer to a panel, tighten the two mounting screws alternately, a little

at a time, so as to keep them at an equal tightness. If the panel screws are tightened

unequally, water may enter the panel.

2) Store the Timer at the specified temperature. If the Timer has been stored at a

temperature of less than -10°C, allow the Timer to stand at room temperature for at least

3 hours before use.

3) Mounting the Timer side-by-side may reduce the life expectancies of internal components.

4)

Use the Timer within the specified ranges for the ambient operating temperature and humidity.

5) Do not use or store the product in the following locations:

• Locations subject to sudden or extreme changes in temperature.

• Locations where high humidity may result in condensation.

• Locations with excessive vibration or shock.

• Locations subject to water.

1) Read this manual carefully before using the product.

2) An inrush current of approx. 14 A will flow for a short time when the power supply

is turned ON. If the capacity of the power supply is not sufficient, the Timer may

not start. Be sure to use a power supply with sufficient capacity.

3) Make sure the power supply voltage and loads are within the specifications and

ratings for the product.

4) Take caution that signal reception is possible, impossible, or indefinite during the

following periods after power ON/OFF. To allow for the startup time of peripheral

devices (sensors, etc.), the Timer starts timing operation between 200 to 250 ms

after power is turned ON. For this reason, if the set value is 249 ms or less in

operations where timing starts from power ON, the time until output turns ON will

be a fixed value between 200 and 250. The present value display will start from

250 ms. (Normal operation is possible for set values of 250 ms or more.) In

applications where a set value of 249 ms or less is required, use start timing with

signal input.

5) No input signals will be accepted from 5 to 505 ms for H5CC-A/L8, from 5 to

105 ms for H5CC-A11F, and from 5 to 1005 ms for H5CC-AUafter the power is

turned OFF.

6) Inrush current generated by turning ON or OFF the power supply may deteriorate

contacts on the power supply circuit. Turn ON or OFF to a device with the rated

current of more than 14 A.

7) Make sure that all settings are appropriate for the application. Unexpected

operation resulting in property damage or accidents may occur if the settings are

not appropriate.

8) Do not leave the Timer for long periods at a high temperature with output current

in the ON state. Doing so may result in the premature deterioration of internal

components (e.g., electrolytic capacitors). Do not install the product close

contact with the heating element.

9) Non-volatile memory is used as backup memory when the power is interrupted.

The write life of the non-volatile memory is 100,000 writes. The non-volatile

memory is written when the power is turned OFF or when switching from function

setting mode or configuration selection mode to run mode.

10) Dispose of the product according to local ordinances as they apply.

11) Do not use because it may be damaged inside the product when the product fall

by mistake.

12)

Confirm the wiring the input and output terminals correctly before power is supplied.

13) Do not use the product near radio wave receivers. Doing so may cause incoming

radio wave interference.

14) Install product so that the load doesn't span the product body.

15) H5CC models with a 24 to 240 VAC/DC power supply use a transformer-free

power supply method in which the power supply terminals are not isolated from

the signal input terminals. In such cases, unwanted current paths may

occasionally burn or destroy internal components depending on the wiring.

Always check the wiring sufficiently before use.

16) Do not wire the terminals that are not used.

17) If there is a transformer or other device with a large inductance component on the

power supply line, the inductance will cause a reverse voltage. If that occurs,

insert a CR filter in the power supply line to reduce the reverse voltage.

18) Do not use in a circuit with the waveform is distorted. The error will increase due

to the influence of the distorted waveform.

Precautions for Correct Use

CAUTION

CAUTION

Conformance to

EN/IEC Standards

• When conforming to EMC standards,

refer to the information provided in this

Instruction Manual for cable selection

and other conditions.

• This is a class A product. In residential

areas it may cause radio interference, in

which case the user may be required to

take adequate measures to reduce

interference.

•

Basic insulation is provided between

power supply and input terminals, between

power supply and output terminals, and

between input and output terminals.

• Basic insulation is provided between

power supply and output terminals, and

between input and output terminals.

When double insulation or reinforced

insulation is required, apply double

insulation or reinforced insulation as

defined in IEC 60664 that is suitable for

the maximum operating voltage with

clearances or solid insulation.

•

Connect the input and output terminals to

devices that do not have any exposed

charged parts.

H5CC-AWSD

Digital Timer

OMRON Corporation

©All Rights Reserved

For details, refer to the latest datasheet (L220-E1).

SUITABILITY FOR USE

Thank you for purchasing the OMRON Product.

To ensure the safe application of the Product, read this

manual carefully before using the Product and always

keep it close at hand when the Product is in use.

3616495-0A (Side-A)

INSTRUCTION MANUAL

EN

Omron Companies shall not be responsible for conformity with any

standards, codes or regulations which apply to the combination of the

Product in the Buyer's application or use of the Product. At Buyer's request,

Omron will provide applicable third party certification documents identifying

ratings and limitations of use which apply to the Product. This information

by itself is not sufficient for a complete determination of the suitability of the

Product in combination with the end product, machine, system, or other

application or use. Buyer shall be solely responsible for determining

appropriateness of the particular Product with respect to Buyer's

application, product or system. Buyer shall take application responsibility in

all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY OR IN LARGE QUANTITIES

WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN

DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Package Contents

• Digital Timer

• Instruction manual (this

document)

• Mounting Adapter, Waterproof

Packing, Terminal Cover

Power supply voltage 12 to 48 VDC/24 VAC, 50/60 Hz

Allowable voltage fluctuation range

85% to 110% of rated supply voltage (12 to 48 VDC: 90% to 110%)

Power consumption Approx. 5.4 VA/3.2 W at 24 VAC/12 to 48 VDC

Operating temperature range -10 to 55°C (-10 to 50°C if Timers are mounted side by side)

(with no icing or condensation)

Storage temperature range -25 to 70°C (with no icing or condensation)

Operating humidity range 25% to 85%

Altitude 2,000 m max.

Recommended fuse 0216.100

Weight Approx. 115 g (main unit only)

Installation environment Over-voltage category Ⅲ, pollution degree 2, indoor use only

(IEC 61812-1)

Input method

No-voltage input ON impedance: 1 kΩmax. (Leakage current: 12 mA when 0 Ω),

ON residual voltage: 3 V max., OFF impedance: 100 kΩmin.

Voltage input High (logic) level: 4.5 to 30 VDC, Low (logic) level: 0 to 2 VDC

(Input resistance: approx. 4.7 kΩ)

No-voltage (NPN) input/voltage (PNP) input (switchable)

Control output

Solid state output Open collector 30 VDC max., 100 mA max.

Residual voltage 1.5 VDC max. (Effective value: Approx. 1 VDC)

Leakage current 0.1 mA max.

Degree of protection IEC IP66

* Individual mounting: Degree of protection on the front panel of the Timer conforms when all

of the following conditions are satisfied:

• The Y92S-P6 waterproof packing and Y92F-30 mounting adapter are used with the Timer.

Use only these parts for replacement.

Display Section

1. Key Protect Indicator (yellow)

2. Control Output Indicator (yellow)

3. Reset Indicator (yellow) (Lit when the

reset input or Reset operation is ON.)

4. Present Value Display (Main Display)

Character height: 10 mm (white)

5. Time Unit Indicators (green) (If the

time range is 0 min, 0.0 min, 0 h, 0.0 h, or

0 h 0 min, these indicators flash to

indicate timing operation.)

6. Set Value Display (Sub-display)

Character height: 6 mm (green)

7. Set Value 1, 2 Indicator (green)

Power

ON Function

setting mode

Run

mode

UP1+UP3 or DW1+DW3

(2 s min.)

UP1+UP3 or DW1+DW3

(2 s min.)

Note: Operate with transistor ON

PLC,

Sensor

6 7 8 9

10

0 V for inputs

Reset

Signal

Gate

Reset

Note: Operate with relay ON

6 7 8 9

10

0 V for inputs

Reset

Signal

Gate

Reset

Note: Operate with transistor ON

Sensor

6 7 8 9

10

0 V for inputs

Reset

Signal

Gate

Reset

Note: Operate with transistor ON

6 7 8 9

10

0 V for inputs

Reset

Signal

Gate

Reset

Note: Operate with transistor OFF

Sensor

6 7 8 9

10

0 V for inputs

Reset

Signal

Gate

Reset

Note: Operate with relay ON

6 7 8 9

10

0 V for inputs

Reset

Signal

Gate

Reset

Note: Operate with transistor ON

Sensor

6 7 8 9

10

0 V for inputs

Reset

Signal

Gate

Reset

Self-diagnostic Functions

The following displays will appear if an error occurs.

e2 sum Memory error

(non-volatile memory) *1 OFF Reset operation Factory

setting

Rplc

*3 No

change

Total run time or Output

ON count has reached

the maintenance forecast.

No

change Reset operation *2 No change

e2 Not lit Memory error (RAM) OFF Turn ON the power

again. No change

e1 Not lit CPU error OFF Either perform Reset

operation or reset

the power supply. No change

Main

display

Sub-

display Description Output

status Correctionmethod Set value

after reset

*1. This includes times when the life of the non-volatile

memory has expired.

*2. This is displayed if the alarm set value for either of the

two outputs is exceeded if a model with two outputs

is used. The total ON count will not be cleared by

using Reset operation.

*3. The normal display and Rplc will appear alternately.

When Reset operation is performed, Rplc will no

longer be displayed even if the alarm set value is

exceeded. (Monitoring is possible, however, because

the Timer will continue without clearing the total run

time and the output ON count.) If the power supply is

turned OFF/ON after the Rplc display is turned OFF

by Reset operation, Rplc will be displayed again. In

order to prevent the display even after the power

supply is turned OFF/ON, change the alarm set value

to equal to or greater than the count value, or change

the alarm set value to 0 to be invalid.

Mode A: Signal ON delay (Timer resets when power

comes ON.)

• Timing starts when the start signal goes ON.

• While the start signal is ON, the timer starts when the

power comes ON or when the reset input goes OFF.

• A sustained control output is used.

Mode F-1: Cumulative (Timer does not reset

when power comes ON.)

• Start signal enables timing (timing is stopped

when the start signal is OFF or when the power

is OFF).

• A sustained control output is used.

Displayed only when forecast value setting is made.

Function setting mode

Precautions for Compliance with

UL Standards and CSA Standards

Display Set value

----.-- s0.01s~9999.99s (default setting)

-----.- s0.1s~99999.9s

------ s1s~999999s

--:--:-- hms 0h0min01s~99h59min59s

-----.- m0.1min~99999.9min

------ m1min~999999min

----:-- hm 0h01min~9999h59min

-----.- h0.1h~99999.9h

------ h1h~999999h

---.--- s0.001s~999.999s

Notice to Users of the H5CC in the USA and Canada

Please use the following installation information instead of the general information in

the instruction manuals in order to use the product under certified conditions of UL and

CSA when the product is installed in the USA or Canada. These conditions are required

by NFPA 70, National Electrical Code in the USA and the Canadian Electrical Code, Part

I in Canada and may vary from information given in the product manuals or safety

precautions.

• Installation in a Panel

H5CC is normally installed on a flat surface in an operation panel. Use a Type 1

Enclosure for the operation panel.

• Environment

Surrounding Air Temperature: -10 to 40°C

• Accessories (Order Separately)

11-pin

11-pin, finger-safe type

8-pin

8-pin, finger-safe type

P2CF-11

P2CF-11-E

P2CF-08

P2CF-08-E

Track Mounting/

Front Connecting

Socket

(48)

57.57.5

Panel

Y92F-30 (provided)

Flush Mounting Adapter

Y92S-P6 (provided)

Waterproof Packing

58

48

15 or greater

60 or greater

□45+0.6

ー0

A

A (48n 2.5) 1

0

n Units mounted

side-by-side

Forecast set value Present value

Set value

Forecast value

0

Forecast output (OUT1)

Control output (OUT2)

* UP1+UP3 or

DW1+DW3

Present value

Set value

Present value

Forecast set value

0.0

0.0

0.0

0.0

Present value

Set value 2

Set value 1

0

Control output 1 (OUT1)

Control output 2 (OUT2)

* UP1+UP3 or

DW1+DW3

Present value

Set value 1

Present value

Set value 2

0.0

0.0

0.0

0.0

6 7 8 9 10

12 13 OUT1

OUT2

(+)(-)

0 V

12345

*

Reset

Signal

Gate

Reset

Power for load

+

Load

Power for load

+

Load

NPN Output PNP Output

Power for load

+

Timer

Inductive

load

Output Operation

Chart Power

Timing Sustained

Timing

Signal

Forecast output

OUT1

Control output

OUT2

Control output

OUT1

Control output

OUT2

Output Operation

Chart

Power

Timing

Signal

Forecast output

OUT1

Control output

OUT2

Control output

OUT1

Control output

OUT2

*

H5CC TIMER

1

7

9

26

12

8

11

10

4

5

3

48

48

H5CC TIMER