Operator's Guide vii

Maintenance

Replacable Units/Ordering Parts ...................................................39

Replacable Units ...................................................................39

Ordering Parts .......................................................................39

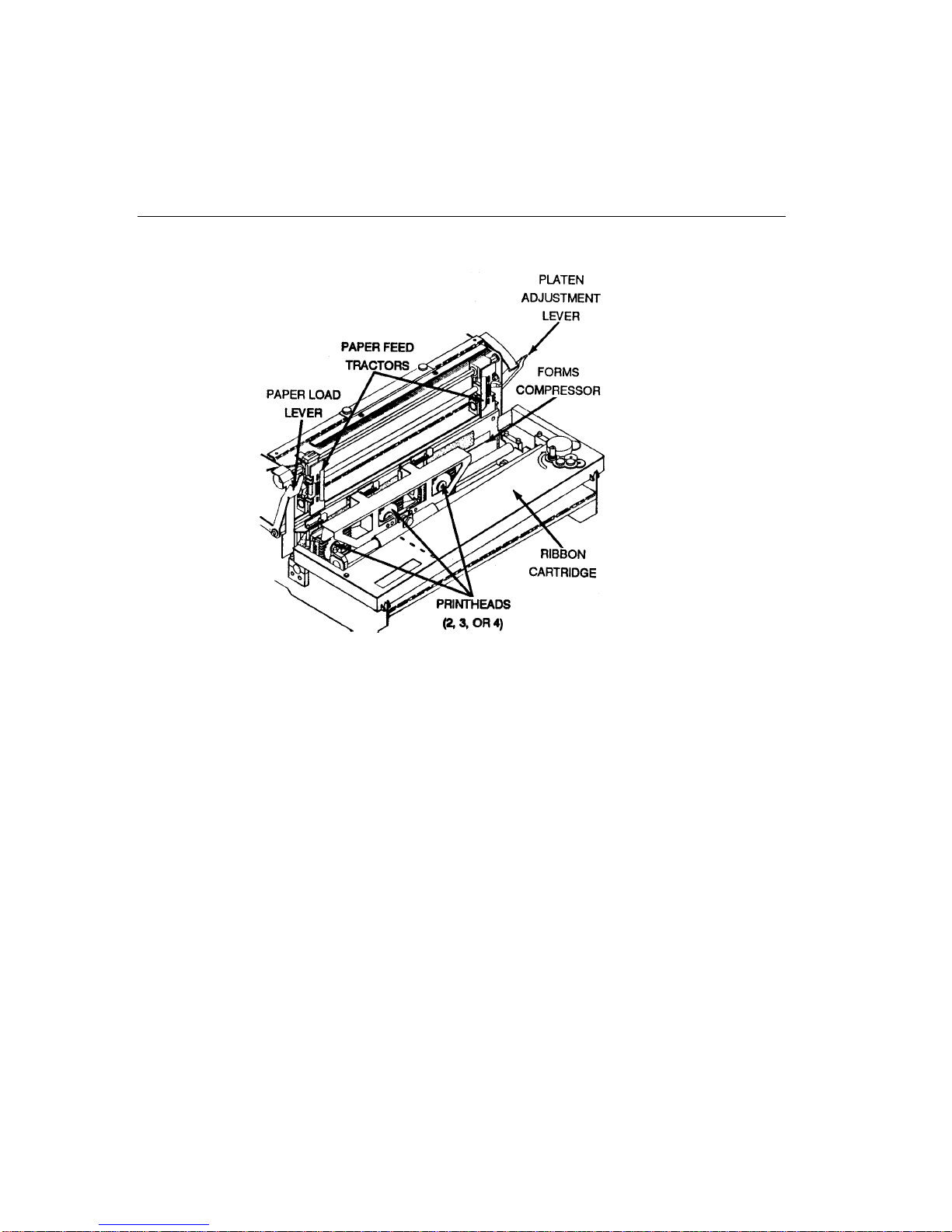

Replacing The Ribbon...................................................................40

Reset Ribbon Count..............................................................43

Replacing A Printhead...................................................................43

Replacing The Forms Compressor................................................47

Cleaning And Lubrication...............................................................51

Problems

Diagnostics ...................................................................................53

Power On Diagnostics ..........................................................53

Menu Diagnostics .................................................................53

Test Print ......................................................................54

Hex Dump .....................................................................55

Problems .......................................................................................57

Servicing................................................................................58

Replace Ribbon Press On Line Message .............................58

Dead Printer ..........................................................................58

Outlet Power .................................................................58

Printer Fuse ..................................................................58

Power On Problems ..............................................................60

Noise, Smoke or Odor...........................................................60

LCD Error Messages.............................................................61

Communication Problems ....................................................61

Paper Jam or Skew...............................................................62

Ribbon Tears ........................................................................63

Print Quality Problems...........................................................63

To Cancel Print .....................................................................64