TABLE OF CONTENTS

Patio Heater Safety Warnings -------------------------------------------------------------1-2

Part List& Hardware -------------------------------------------------------------------------2-3

Exploded View ----------------------------------------------------------------------------------4

Patio Heater Assembly ----------------------------------------------------------------------4-7

Leak Testing ----------------------------------------------------------------------------------- 10

Gas Requirement ----------------------------------------------------------------------------- 10

Connecting To a Gas Cylinder -------------------------------------------------------------- 11

Operating Instructions ----------------------------------------------------------------------- 12

Important Safety Rules -----------------------------------------------------------------------11

Maintenance -----------------------------------------------------------------------------------12

Servicing --------------------------------------------------------------------------------------- 12

Storage -----------------------------------------------------------------------------------------13

Troubleshooting------------------------------------------------------------------------------- 14

Technical Data ---------------------------------------------------------------------------------14

Guarantee --------------------------------------------------------------------------------------14

Discard ------------------------------------------------------------------------------------------

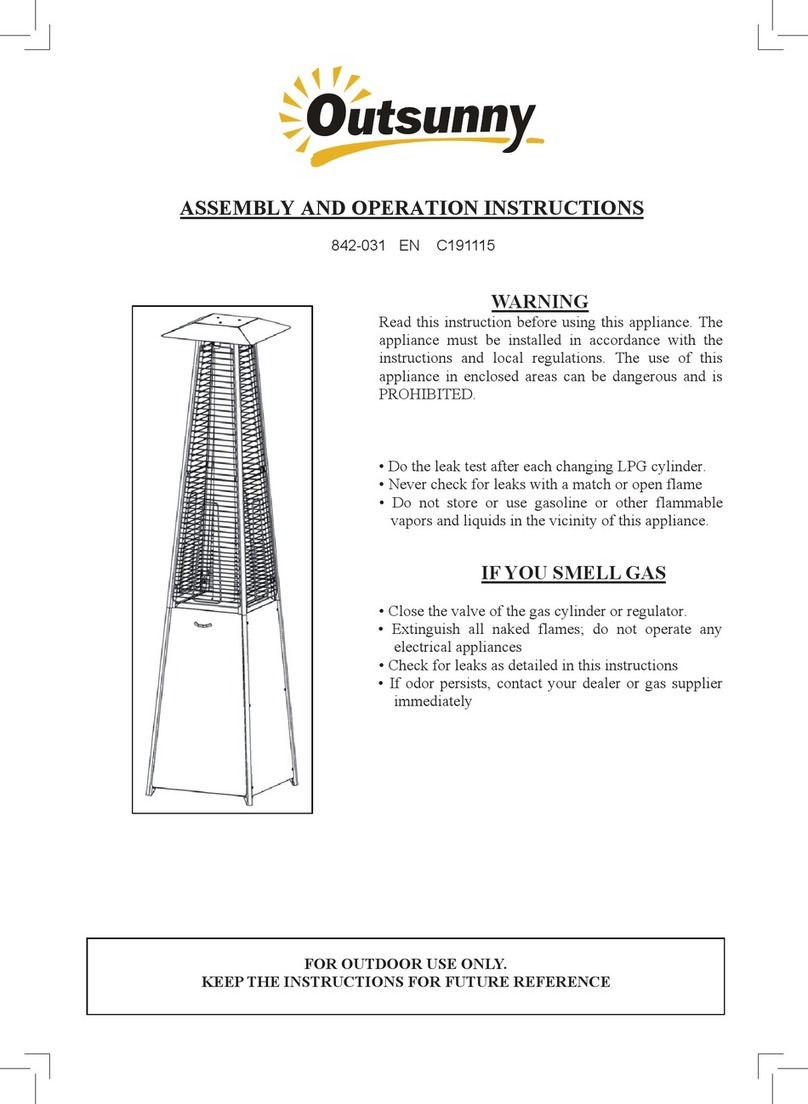

PATIO HEATER SAFETY WARNINGS

PLEASE READ THE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION AND

USE.

This appliance must be used outdoors or in a well ventilated area, and should not

be installed or used indoors.

Change the gas cylinder in a well ventilated area, away from any inflammation

sources.

The cylinder must be stored outdoors or in a well ventilated area.

Storage this appliance indoors is permissible only if gas cylinder is disconnected

and removed from the appliance.

Do not move this appliance when in operation, or after it has been turned off

before the temperature has cooled down.

Do not attempt to alter the appliance in any manner. Do not paint the radiant

screen, control panel or reflector.

Do not obstruct the ventilation holes of the cylinder housing.

The appliance must be installed and gas cylinder stored in accordance with local

gas fitting regulations.

Shut off the valve at the gas cylinder or the regulator before moving the

appliance.

Repairs should be done by a qualified person.

In case of violent wind, particular attention must be taken against tilting of the

appliance.

Check that the regulator seal is correctly fitted and able to fulfil its function.

Close the gas supply at the valve of the gas cylinder or the regulator after use.

Do not use this appliance until all connections havebeen leak tested.

In the event of gas leakage, the appliance shall not be used or if alight, the gas

supply shall be shut off and the appliance shall be investigated and rectified before

it is used again.