Jet Swim Motion

MA30-09 GB

ENGLISH

rt.no.

ev.no.

cale

esined by pproved by

evised by ate

rawn by ate

rawin number

ssembly drawin no.

urface treatment

part of

The tolerance class in accordance with this

ox , pplands sby, weden

Phone , ax

et swim motion mursten sprnsiss

This document and its contents are the exclusive

property of Pahléns and may not be copied,

reproduced, transmitted or communicated to a third

party, or used for any purpose without written permission.

rt.no.

ev.no.

cale

esined by pproved by

evised by ate

rawn by ate

rawin number

ssembly drawin no.

urface treatment

part of

The tolerance class in accordance with this

ox , pplands sby, weden

Phone , ax

et swim motion beton sprnsiss

This document and its contents are the exclusive

property of Pahléns and may not be copied,

reproduced, transmitted or communicated to a third

party, or used for any purpose without written permission.

This document and its contents are the exclusive

property of Pahléns and may not be copied,

reproduced, transmitted or communicated to a third

party, or used for any purpose without written permission.

rt.no.

ev.no.

cale

esined by pproved by

evised by ate

rawn by ate

rawin number

ssembly drawin no.

urface treatment

part of

The tolerance class in accordance with this

ox , pplands sby, weden

Phone , ax

m

isch vetsad

A A

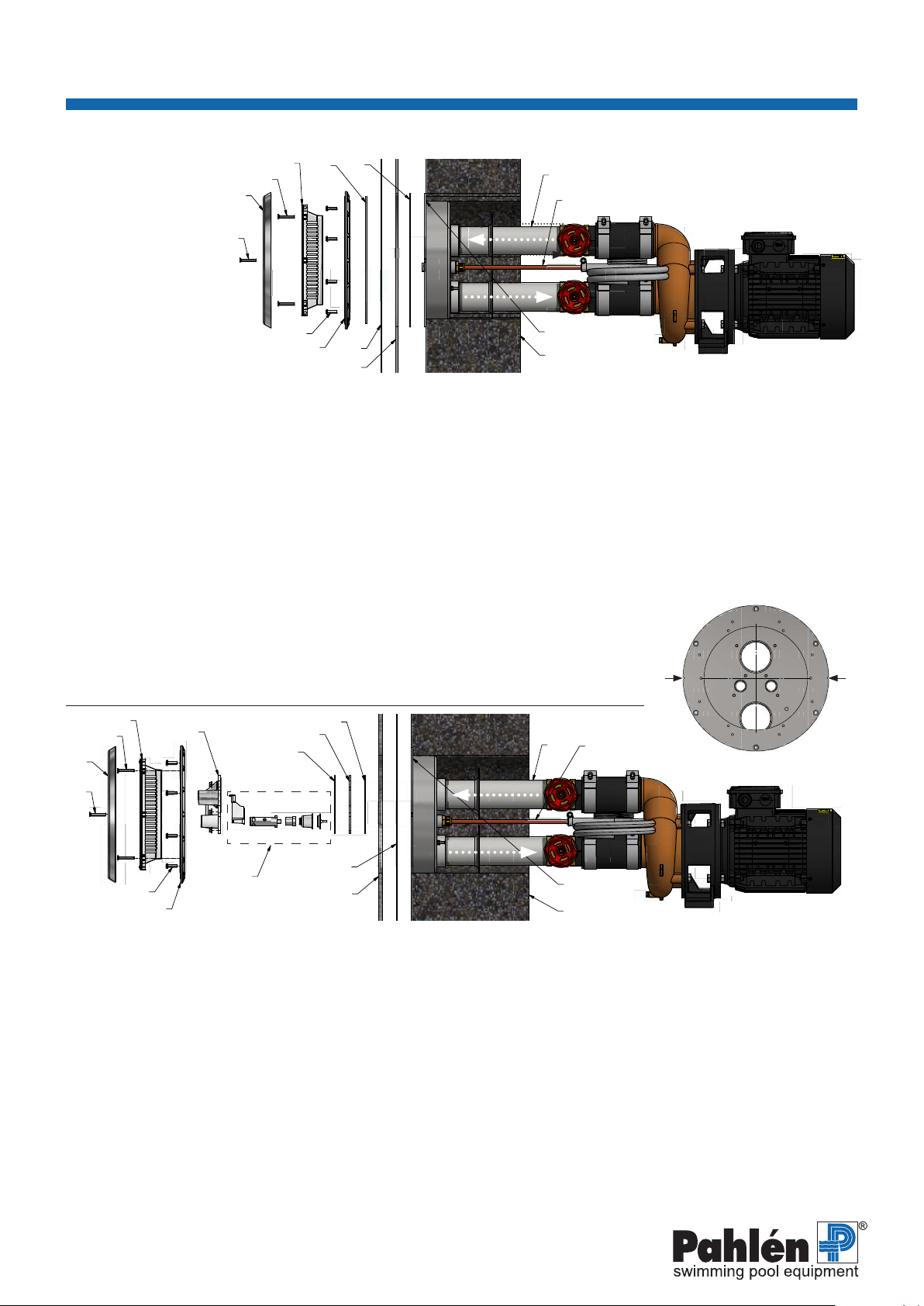

Concrete pool without liner

Concrete pool with tiles/mosaic: efore assemblin in the form, the nole and the parts be-

hind them are removed. spacer and an extra aset are added in the order as shown

in the imae above when the nole is put bac in place T mouldin the stud bolts in the

recess are lubricated. The nuts are tihtened to . m.

Painted concrete pools: Do not require the above step.

1. ssembly the recess in the form, see iure . The ane on the niche should be in line

with the nished pool wall.

N.B.! Reinforcement present must not be closer than 50 mm from stainless steel material.

. Connect the start hose to the niche.

3. Attach all socketing pipes in the niche prior to moulding. All threads must be tightened with

thread tape.

4. ould. hen the concrete has burned and any tilin is completed, install the tension rin and

front with intake grates, tighten the screws to a torque of 5 Nm.

these screws must be lubricated.

5. Connect the hose for the air admixture and tighten the hose clamp.

Attach the opening of the hose 100 mm above the surface of the water, behind the pool wall.

. Connect the start hose

with a loo at least mm over the surface of the water

to the control box.

. onnect pipes and valves to the pump. Threads are sealed with thread seal tape.

Thick pool wall with liner

(Masonry block, thermoblock, concrete etc.)

N.B.! Any reinforcement present must not be closer than 50 mm from stainless steel material.

The pool wall must be done bein polished before any constituent parts are installed.

1. ae a hole in the pool wallform and attach the niche, see iure .

The ane on the niche should be in line with the nished pool wall.

. Connect the start hose to the niche.

3. Attach all socketing pipes in the recess. All threads must be tightened with thread tape.

4. ast or else bric up with masonry stones.

5. ttach the selfadhesive aset onto the niches ane.

. Install the pool liner with water up to 5 cm under the house.

. crew the clampin rin and the rubber aset in place aainst the ane of the niche,

5 Nm in torque, the screws must be lubricated.

. Cut away the pool liner against the inside of the clamping ring.

9. nstall the intae rate and the front these screws must be lubricated.

10. Connect the hose for the air admixture and tighten the hose clamp. Attach the other opening of

the hose 100 mm above the surface of the water, behind the pool wall.

11. Connect the start hose

with a loop at least mm over the surface of the water

to the control box.

. Connect pipes and valves to the pump. All threads must be tightened with thread tape.

Installation in Thick Pool Walls

Sample image:

concrete without liner

1. Niche

. ocetin pipes, water

. ocetin pipes, airstart

4. —

5. —

. lampin rin

. crew

. ntae rate

9. Screw

10. Front

11. Screw

. Pool framewor

13. Polish

. Tiletile cement

15. Gasket

. pacer

. Parts of the nole

. ole

Figure 1.2

Recess seen from the front.

UP

Sample image:

masonry block with liner

1. Niche

. ocetin pipes, water

. ocetin pipes, airstart

4. Self-adhesive gasket

5. Gasket

. lampin rin

. crew

. ntae rate

9. Screw

10. Front

11. Screw

. Pool frame bric

. all coverin

14. Liner