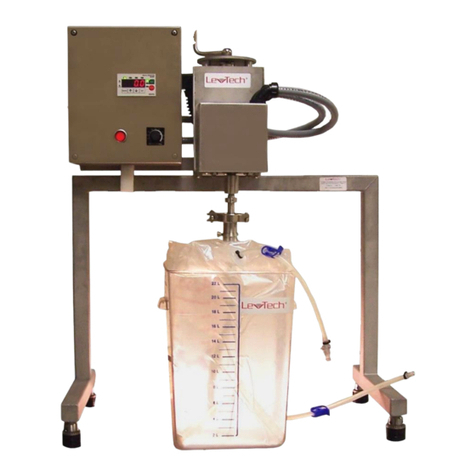

Minimate™TFF Capsule

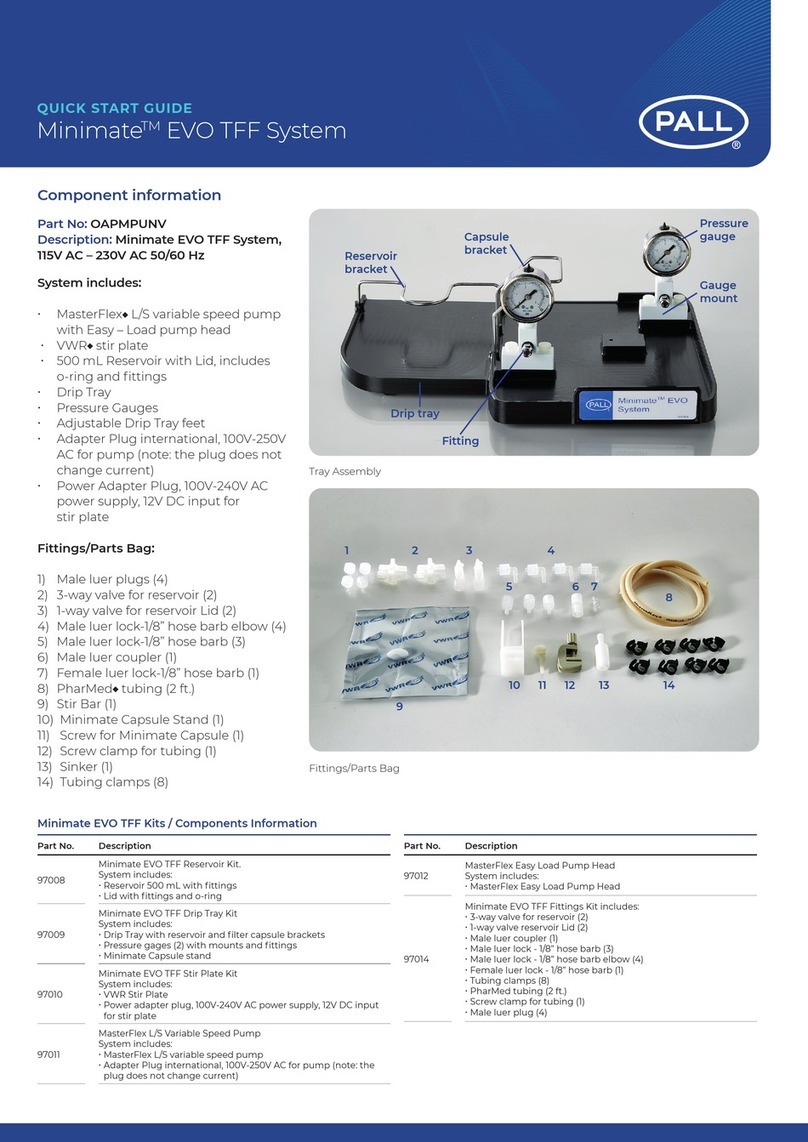

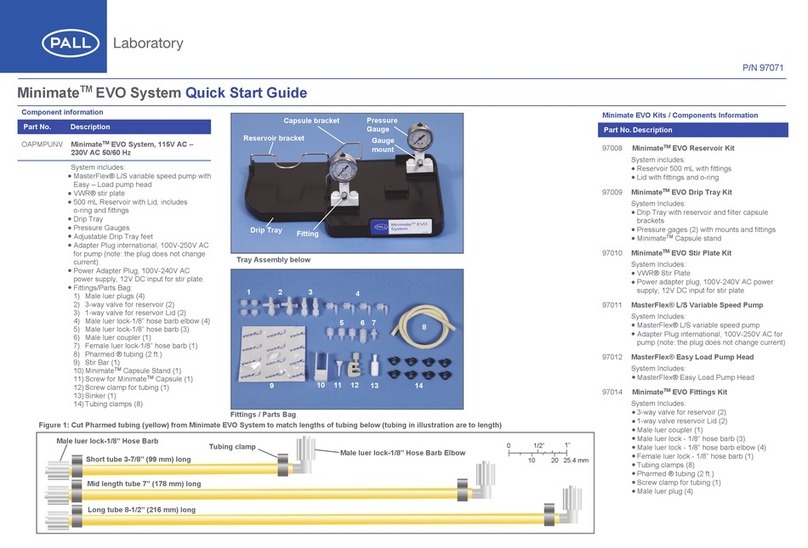

Component Information

Part No. Description

OAxxxC12 Minimate TFF Capsule

88216 Minimate Fitting Kit

Kit Contains:

AMale luer to 3.2 mm (1/8") hose barb

BFemale luer to 3.2 mm(1/8") hose barb

C3.2 mm (1/8") tubing

DTubing screw clamp

ETubing clamps

FAdhesive strips (loop and hook)

FS700X06 3-port valves (not supplied)

Assemble the Components

Installation (Refer to schematic on reverse side)

1. Remove the caps from the feed and retentate ports of the

Minimate TFF capsule.

2. Screw a male-luer-to-hose-barb connector (included) into

the feed/retentate ports.

3. Cut a length of tubing long enough to reach from the

reservoir, through the pump head to the capsule.

4. Connect the tubing to the hose-barb on one of the feed

ports. Install the tubing in the pump head. Put the other

end of the tubing into the reservoir.

5. Cut another piece of tubing, long enough to return from

the retentate port to the sample reservoir. Attach the tubing

to the retentate hose-barb and put the other end in the

reservoir. Place the retentate screw clamp on the retentate

tubing close to the retentate port (after the pressure gauge

if installed). Secure in place but do not tighten to restrict

the tubing.

6. Remove one of the filtrate caps. Choose port that is

highest in orientation. This allows air to be expelled from

the capsule.

7. Attach a female luer-to-hose-barb fitting to the filtrate port.

8. Cut a length of tubing long enough to reach from the

filtrate port to your filtrate collection vessel. Connect

the tubing to the filtrate hose barb.

9. Install a tubing clamp over each piece of tubing where it

connects to the hose barb. Pinch the clamp to tighten.

Notes:

1. Do not discard caps. They are required for storage.

2. Keep tubing lengths as short as possible to reduce

hold-up volume.

3. Feed and retentate ports are interchangeable. Depending

on the orientation of the capsule, choose the port that is

at the lowest elevation as the feed port. This allows for air

to be easily expelled when liquid is pumped through the

capsule.

4. If a pressure gauge or transducer is used, the feed or

retentate tubing connects to the pressure device, which

must then be connected to the feed or retentate ports.

5. Pall strongly recommends the use of pressure gauges or

transducers connected on both the feed and retentate

ports. If only one gauge is available, it should be used

on the feed port. The use of pressure gauges allows

accurate adjustment of feed pressures and provide for

better reproducibility between process runs. They also

help diagnose system problems.

Quick Start Guide PN 88200

Minimate Fitting Kit 3-port valves

A

C

D

E

F

B