1. Introduction

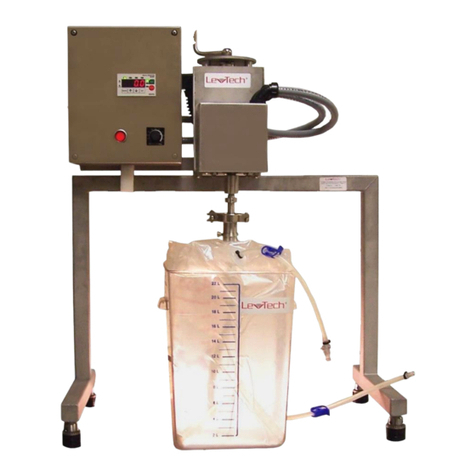

The following procedures are provided for installation of the Pall Allegro 200 single-use mixer

incorporating Allegro 3D mixer biocontainers with a capacity of 200 . The instructions

contained in the product documentation should be read thoroughly because they contain

valuable information gained by extensive experience. It is very important that all instructions are

carefully followed and, where appropriate, they should be incorporated into the user’s standard

operating procedures. If some of the procedures do not suit your needs, please consult Pall or

your local distributor before finalizing your system. Use of this product in a manner other than in

accordance with Pall’s current recommendations may lead to injury or product loss. Pall cannot

accept liability for such injury or loss.

2. Warning

Operation outside the specifications defined in the product data sheet or with fluids

incompatible with materials of construction may cause personal injury and result in damage

to the equipment. Incompatible fluids are fluids that may chemically attack, soften, stress,

attack or otherwise adversely affect the materials of construction. Please refer to Pall for

exact limits for contact fluids and conditions.

3. Receipt of Equipment

Allegro 200 mixer hardware:

1. Use appropriate equipment when removing the mixer hardware from the shipping container.

2. Take care when removing the supplied mixer hardware from the shipping container.

3. ocate or store the hardware in an appropriate indoor location. The equipment is designed

for operation in clean rooms and classified areas and as such should be maintained in a

clean state and stored when not in use in an appropriate clean location free from adverse

environmental conditions.

4. Only use mixer when brakes are engaged on the castors.

5. Do not attempt to move tote during mixing.

6. Use on even surface.

Caution:

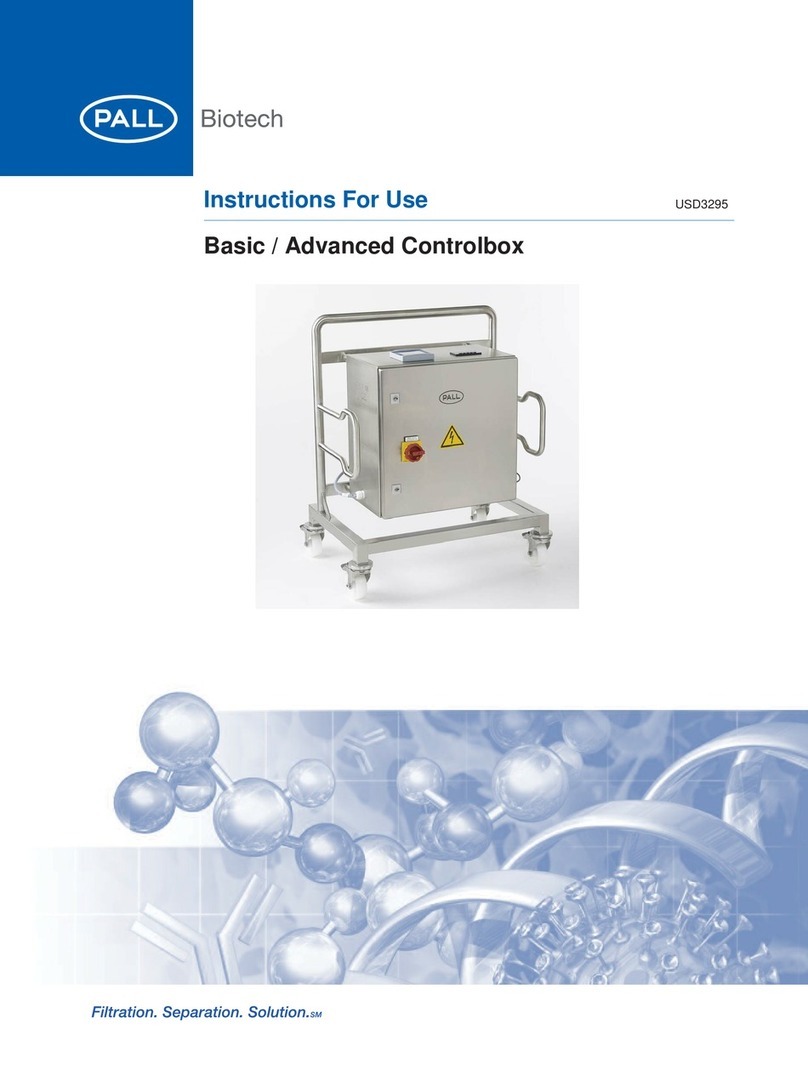

The UCI is configured for correct operation prior to delivery and is therefore not required

to be opened during normal operation. The UCI should only be opened by a qualified

servicing engineer.

Allegro single-use systems are typically sterilized by gamma irradiation.

1. Store the Allegro 3D system in clean, dry conditions between 4 and 40 °C without

exposure to radiation sources like direct sunlight and, wherever practical, in the

packaging as delivered.

2. Do not remove from packaging until just before use.

3. Check that the packaging is undamaged prior to use.

Caution:

1. Avoid the use of sharp blades or pointed instruments that could damage the

Allegro mixer system and other system components.

2. Do not open the packaging by forcing any of the system components through

the sealed end because this can generate particulate contaminants.

3. Ensure that the system selected is suitable for the application.

4. The single-use system used in the Allegro 200 L mixer unit is designed for

single use only.

3

USD 2743 www.pall.com/biopharm