1Safety

1.1 Rating plate ............................................................................................................................................ 4

1.2 Safety instructions (warning notes) ........................................................................................................ 5

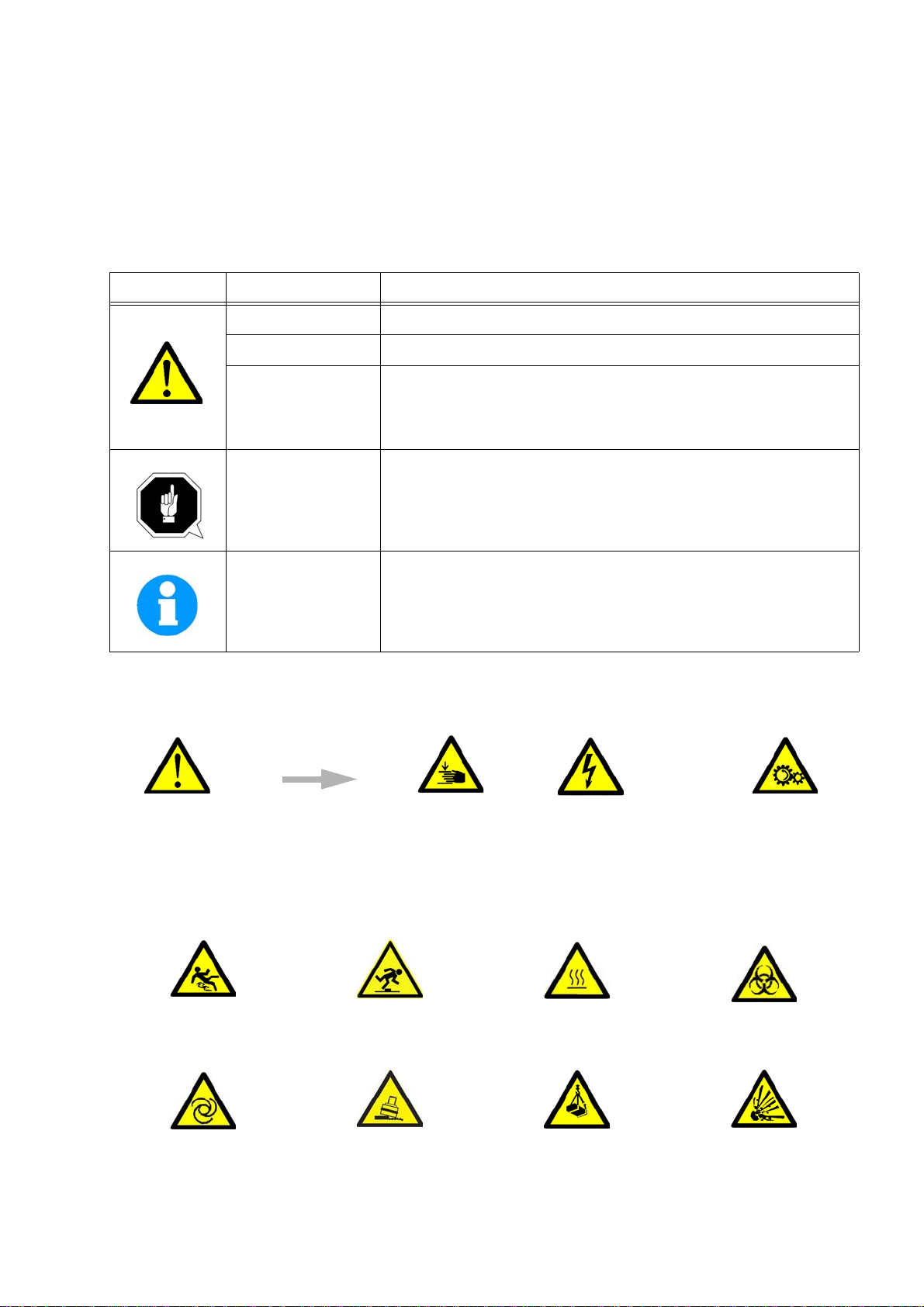

1.2.1 Classification of hazards ............................................................................................................. 5

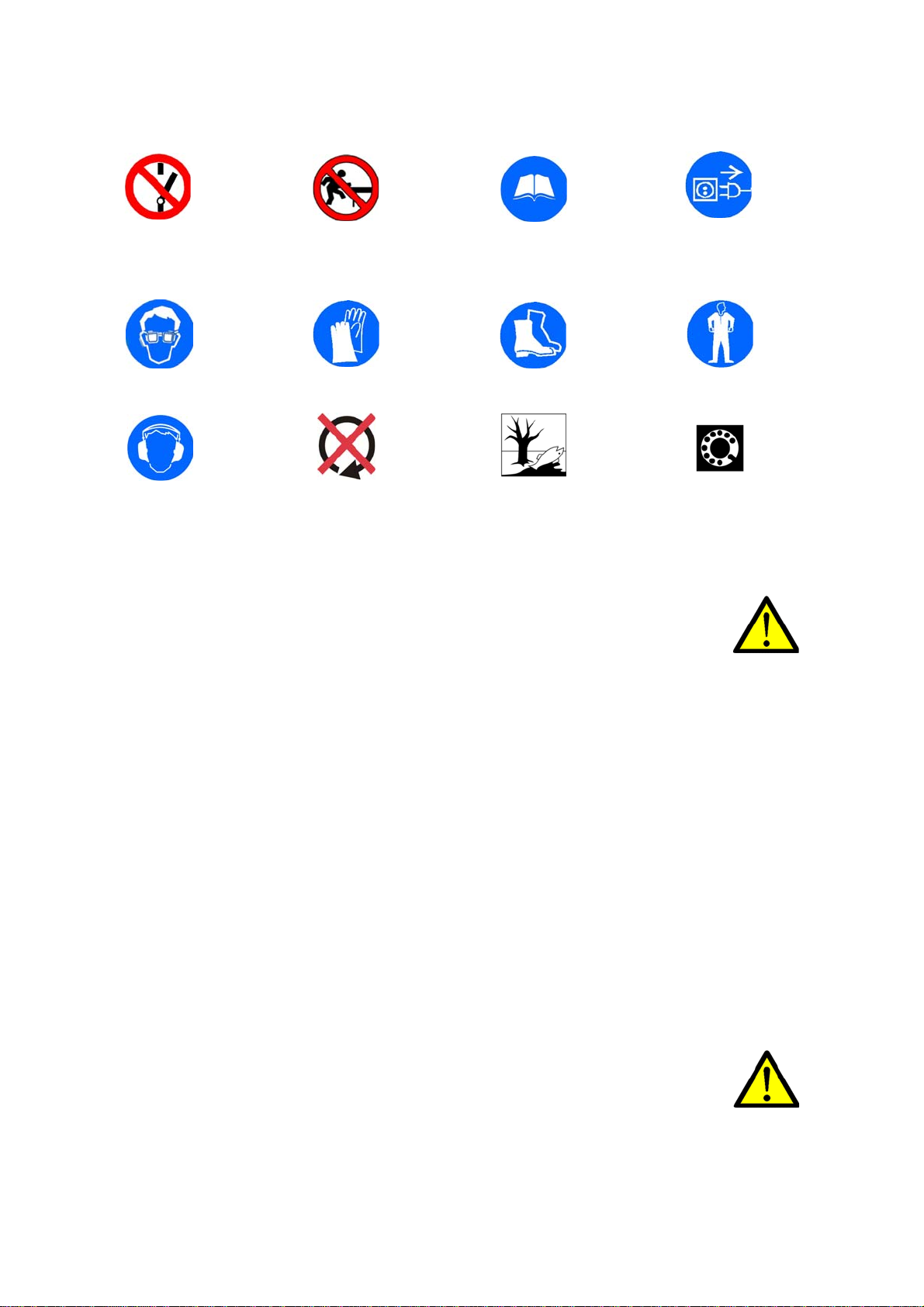

1.2.2 Other pictograms......................................................................................................................... 5

1.3 Intended use........................................................................................................................................... 6

1.4 Reasonably foreseeable misuse ............................................................................................................ 7

1.4.1 Avoiding misuse.......................................................................................................................... 7

1.5 Possible dangers caused by the drilling machine .................................................................................. 7

1.6 Qualification............................................................................................................................................ 8

1.6.1 Target group private users.......................................................................................................... 8

1.6.2 Obligations of the User................................................................................................................ 8

1.6.3 Additional requirements regarding the qualification .................................................................... 8

1.7 User positions......................................................................................................................................... 9

1.8 Safety measures during operation ......................................................................................................... 9

1.9 Safety devices ........................................................................................................................................ 9

1.10 Safety check..........................................................................................................................................10

1.11 Emergency-stop switch .........................................................................................................................10

1.11.1 Master switch .............................................................................................................................10

1.11.2 Drill chuck guard ........................................................................................................................ 11

1.12 Personal protective equipment...............................................................................................................11

1.13 Safety during operation .........................................................................................................................12

1.14 Safety during maintenance.....................................................................................................................12

1.14.1 Disconnecting and securing the drilling machine........................................................................12

1.15 Using lifting equipment ...........................................................................................................................12

1.15.1 Mechanical maintenance ...........................................................................................................12

1.16 Accident report ......................................................................................................................................13

1.17 Electronics.............................................................................................................................................13

1.18 Inspection deadlines.............................................................................................................................. 13

2 Technical specification

2.1 Emissions ..............................................................................................................................................14

2.2Dimensions DH28FS(9680130 ) ............................................................................................................16

3 Assembly

3.1 Scope of delivery ...................................................................................................................................18

3.2 Transport ...............................................................................................................................................18

3.3 Set-up and assembly.............................................................................................................................18

3.3.1 Installation siterequirements......................................................................................................19

3.4 Installation..............................................................................................................................................19

3.4.1 Fixing..........................................................................................................................................19

3.5 First commissioning...............................................................................................................................20

3.5.1 Electrical connection ..................................................................................................................20

3.5.2 Warming up the machine ...........................................................................................................21