Palmgren Operating Manual & Parts List 84261A

5

INSTALLATION (CONTINUED)

•Do not remove or alter grounding prong in any manner. In the

event of a malfunction or breakdown, grounding provides a

path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals of plug

when installing or removing from outlet.

•Plug must be plugged into matching outlet that is properly

installed and grounded in accordance with all local codes and

ordinances. Do not modify plug provided. If it will not fit in out-

let, have proper outlet installed by a qualified electrician.

•Inspect tool cords periodically, and if damaged, have repaired

by an authorized service facility.

•Green (or green and yellow) conductor in cord is the grounding

wire. If repair or replacement of the electric cord or plug is nec-

essary, do not connect the green (or green and yellow) wire to

a live terminal.

•A 2-prong wall receptacle must be replaced with a properly

grounded 3-prong receptacle installed in accordance with

National Electric Code and local codes and ordinances.

WARNING: Any receptacle replacement should be performed by

a qualified electrician.

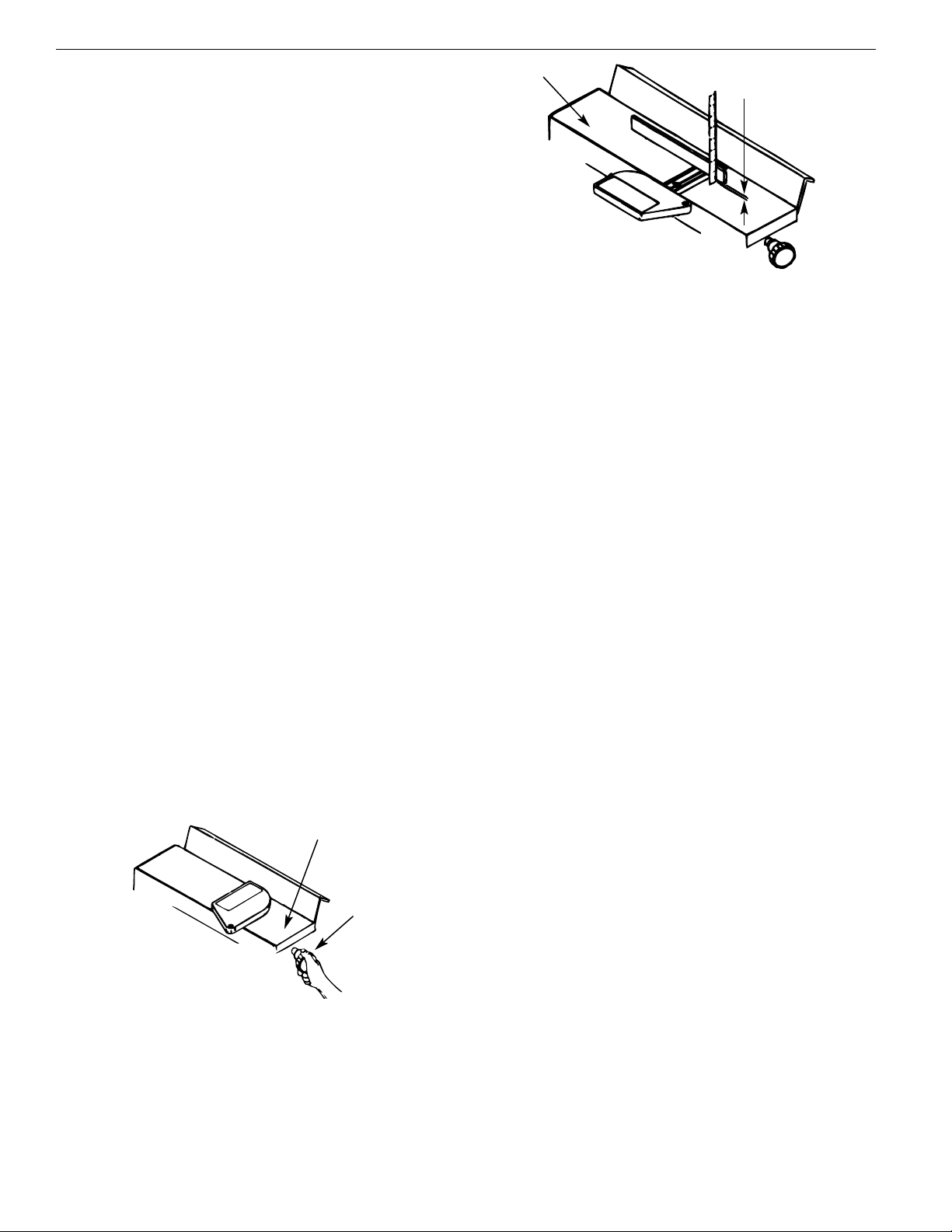

A temporary 3-prong to 2-prong grounding adapter (see Figure 8)

is available for connecting plugs to a two pole outlet if it is proper-

ly grounded.

•Do not use a 3-prong to 2-prong grounding adapter unless

permitted by local and national codes and ordinances.

(A 3-prong to 2-prong grounding adapter is not permitted

in Canada.)

Where a 3-prong to 2-prong grounding adapter is permitted,

the rigid green tab or terminal on the side of the adapter must

be securely connected to a permanent electrical ground such

as a properly grounded water pipe, a properly grounded outlet

box or a properly grounded wire system.

•Many cover plate screws, water pipes and outlet boxes are not

properly grounded. To ensure proper ground, grounding means

must be tested by a qualified electrician.

EXTENSION CORDS

•The use of any extension cord will cause some drop in voltage

and loss of power.

•Wires of the extension cord must be of sufficient size to carry

the current and maintain adequate voltage.

•Use the table to determine the minimum wire size (A.W.G.)

extension cord.

•Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

•If the extension cord is worn, cut or damaged in any way,

replace it immediately.

EXTENSION CORD LENGTH

Wire Size A.W.G.

Up to 50 ft.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

50-100 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

NOTE: Using extension cords over 100 ft. long is not recommended.

MOTOR

Jointer/planer is supplied with a 1 HP motor.

The 120 Volt AC universal motor has the following specifications:

Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hertz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Single

Cutterhead RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10,000

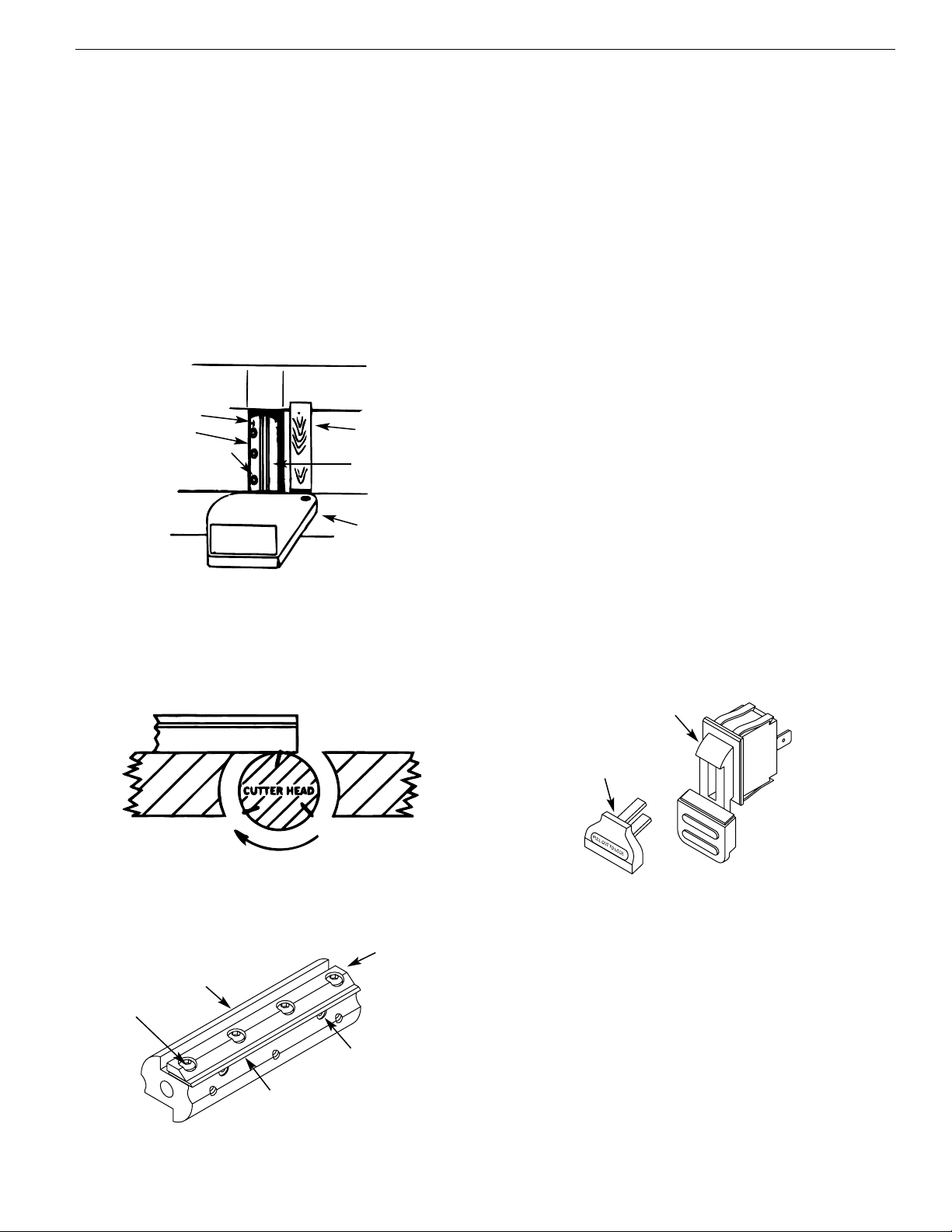

ELECTRICAL CONNECTIONS

WARNING: Make sure unit is turned off and disconnected from

power source before inspecting any wiring.

The unit is wired as illustrated in the wiring schematic (see Figure 9).

The motor is assembled with an approved three conductor cord to

be used on 120 volts as indicated. The power supply to the motor

is controlled by a double pole locking rocker switch.

•Remove the key to prevent unauthorized use.

The power lines are inserted directly onto the switch.The green

ground line must remain securely fastened to the frame to proper-

ly protect against electrical shock.

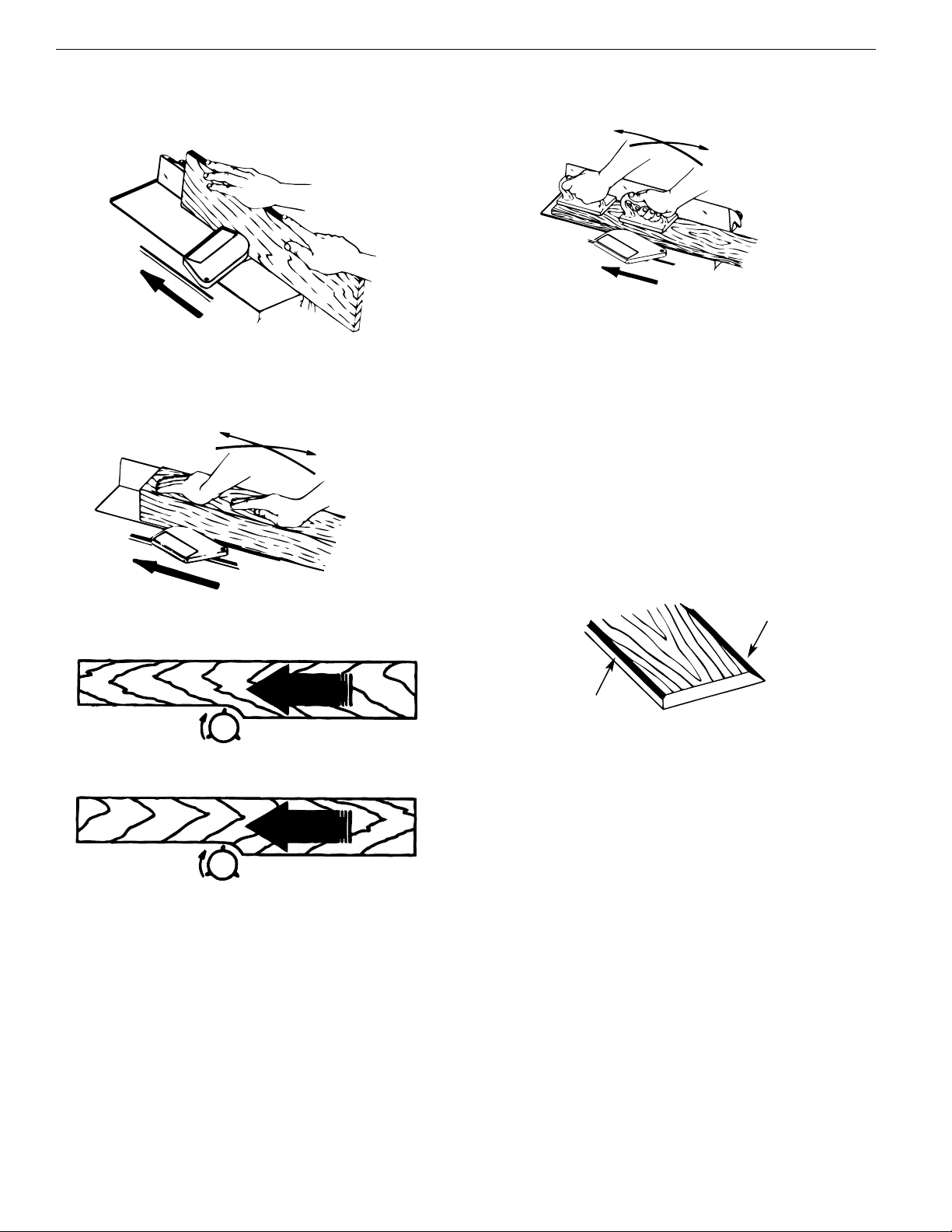

OPERATION

Refer to Figures 10-20, pages 6-8.

OPERATION SAFETY RULES

Jointing is a surfacing operation in which a small amount of wood is

removed from the edges and faces of boards to get smooth, straight

and even surfaces such that the two edges that run across the plan-

ing blocks would fit together perfectly, forming a seamless joint.

Planing refers to the sizing of lumber to a desired thickness while

creating a level surface parallel to the opposite side of the board.

Depth of cut is the term used to indicate how deep the blades will

cut into the workpiece.

WARNING: Operation of any power tool can result in foreign

objects being thrown into eyes which can result in severe eye

damage. Always wear safety goggles complying with United States

ANSI Z87.1 before commencing power tool operation.

WARNING: For your own safety, read all of the instructions and

safety precautions before operating tool.

•Know general power tool safety. Make sure all precautions are

understood (see pages 2, 3, 5 and 6).

•Whenever adjusting or replacing any parts on jointer/planer,

turn switch off and remove plug from power source.

•Make sure all guards are properly attached and securely

fastened.

•Make sure all moving parts are free from interference.

•Always wear eye protection or face shield.

•Make sure blades are aligned and properly attached to cutter-

head.

Figure 8 – 2-Prong Receptacle with Adapter

Make Sure This Is

Connected To A

Known Ground

2-Prong Receptacle

Grounding Lug

Adapter

3-Prong Plug

Figure 9 – Wiring Schematic

Green

White

To

Motor

To

Power

White

Switch

Black Black