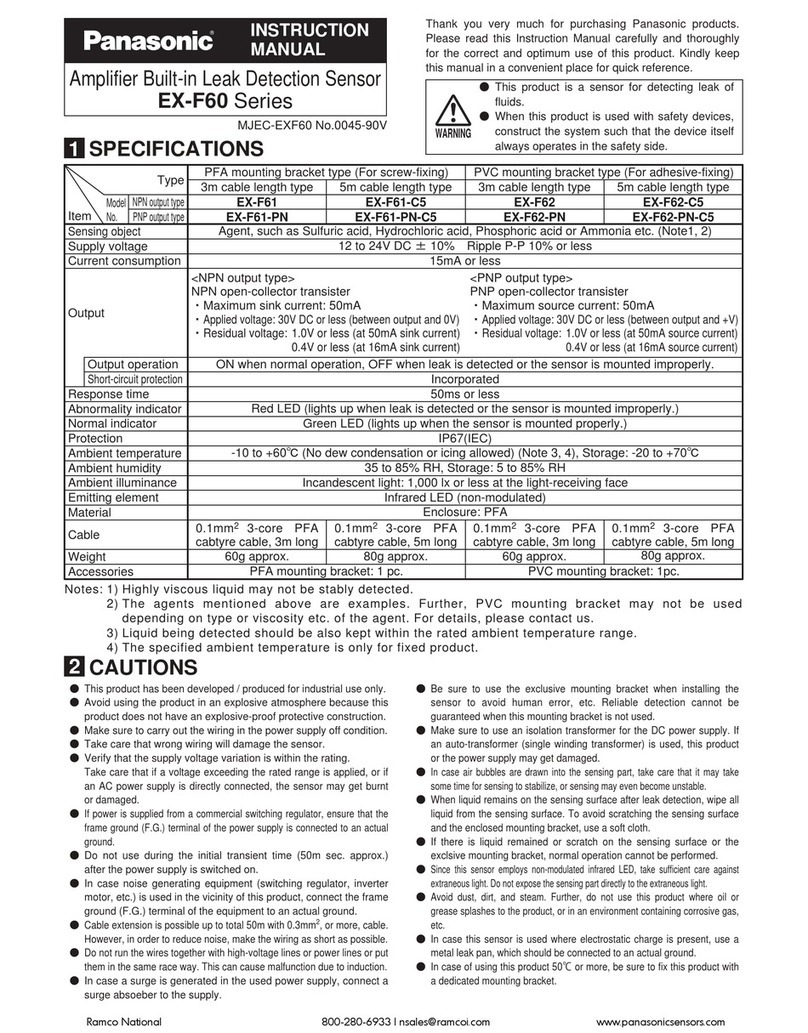

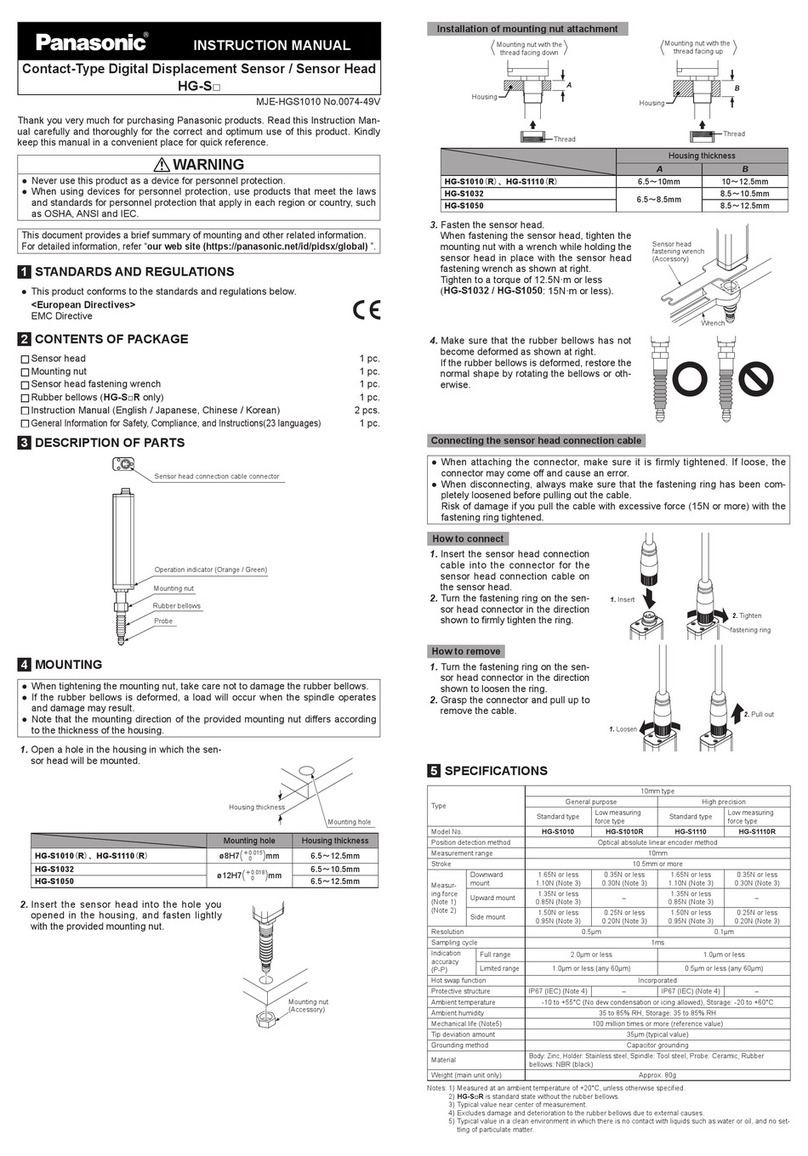

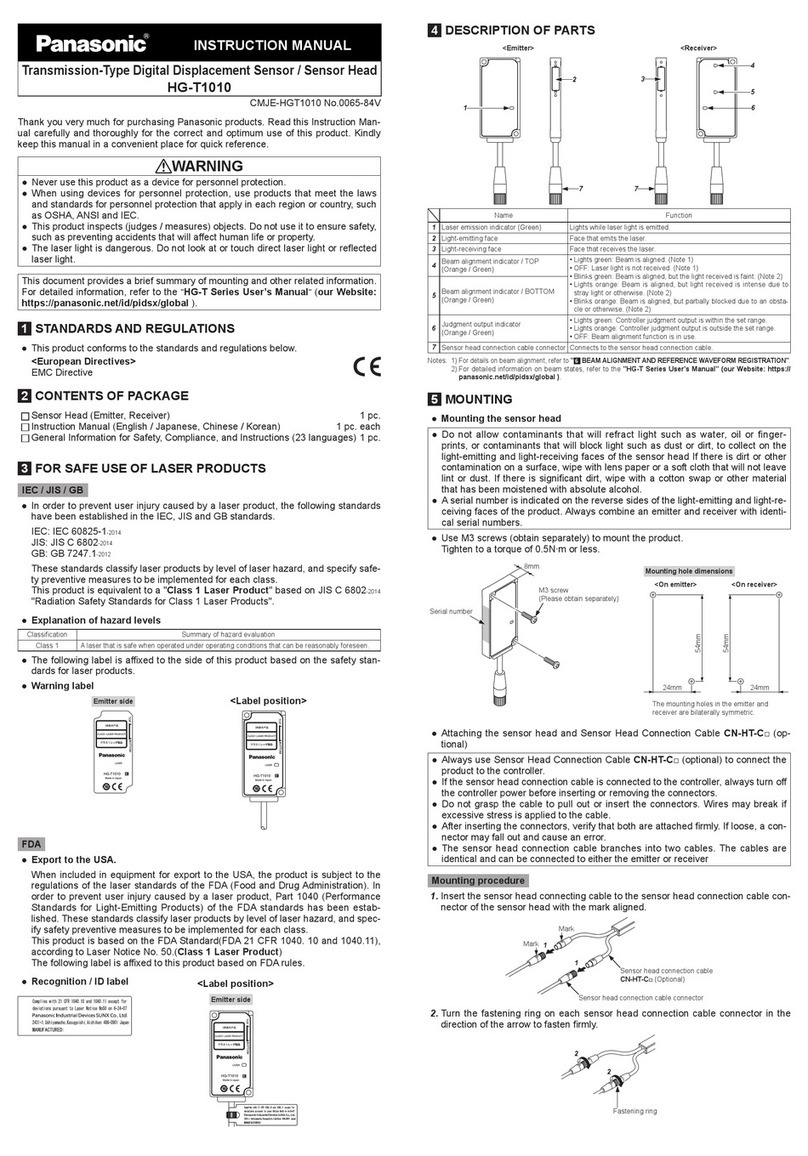

7BEAM AXIS ADJUSTMENT FUNCTION AND REFERENCE

WAVEFORM REGISTRATION

●Be sure to register a reference waveform after installing the sensor head. If the

reference waveform is not registered, the product cannot measure correctly.

●For detailed information, refer to the “HG-T Series User’s Manual”.

●

By pressing and holding the RIGHT and ENTER keys simultaneously for 2 seconds,

you can display the sensor head beam status on the digital display on the controller.

< When beam axis is aligned properly >Long press RIGHT key + ENTER key for 2 seconds

●If the beam axis is not aligned, you conduct adjustment by checking the digital

display on the controller.

●Align the beam axis, and then press the ENTER key to save the reference wave-

form data in the EEPROM of the sensor head beam receiver.

Press ENTER key Reference waveform being registered

Registration of reference

waveform completed

8MODE SELECTION

For details on the procedures for operating the product, refer to the “HG-T Series

User’s Manual”.

●The modes and shortcut functions that can be used from the home screen after

the power is turned ON are as follows.

LEFT key

UP key

RIGHT key

ENTER key

DOWN key

EXIT key

Preset key

●Teaching mode (long press LEFT key for 2 seconds)

You can set the HIGH set value and LOW set value.

●HIGH set value ne adjustment function (short-press UP key)

You can ne adjust the HIGH set value as needed.

●LOW set value ne adjustment function (short-press DOWN key)

You can ne adjust the LOW set value as needed.

●Display switching mode (long press UP key for 2 seconds)

You can change the display of the digital display / SUB (green) as needed for the task.

●Preset (short-press PRESET key)

You can perform zero-point adjustment, and shift to any preset value.

You can cancel preset by long-pressing the preset key for 2 seconds.

●Bank mode (long press DOWN key for 2 seconds)

You can write / read the HIGH set value or LOW set value to / from a specied bank (1 to 3).

●Setting mode (long press RIGHT key for 2 seconds)

You can change basic settings or congure advanced function settings.

●Key lock (long press ENTER key + EXIT key for 3 seconds)

This prevents accidental key operations during measurement.

9CAUTIONS

●For the controller DC power supply, only use a power supply that is isolated by

means of an isolation transformer or otherwise.

●Risk of short-circuiting and damage to the controller or power supply if a trans-

former such as an auto transformer is used. Risk of short-circuiting and damage

to the controller or power supply if incorrectly mounted or connected.

●

The controller HG-TC□ is designed to be used with the special sensor head HG-T□.

If used with other than the special sensor head option, the specications will not

be met and product malfunctioning or damage may occur.

●This product has been developed / produced for industrial use only.

●This product uses an EEPROM. The EEPROM has a service life of one million

setting operations.

● Do not use this product outside the range of the specications. Risk of an accident

and product damage. There is also a risk of a noticeable reduction of service life.

● Verify that the supply voltage uctuations are within the rating.

●If power is supplied from a commercial switching regulator, ensure that the frame

ground (F.G.) terminal of the power supply is connected to an actual ground.

●Do not use during the initial transient time after the power supply is switched ON.

●Make sure that the power supply is OFF while performing wiring or connecting a

slave unit work.

●

Take care that short-circuit of the load or wrong wiring may burn or damage the product.

●

After you have completed wiring work, check the wiring carefully before switching on the power.

●Do not wire in parallel with a high-voltage line or power line, or run through the

same conduit. Risk malfunctioning due to induction.

●

Do not apply stress such as excessive bending or pulling to the extracted part of a cable.

●This product is suitable for indoor use only.

●Avoid dust, dirt, and steam.

●

Do not use this sensor in places where it may come in contact with corrosive gas, etc.

●

Ensure that the product does not come into contact with organic solvents such as thinner.

●Ensure that the product does not come into contact with strong acid or alkaline.

●Ensure that the product does not come into contact with oil or grease.

●

This product cannot be used in an environment containing ammable or explosive gases.

● Performance may not be satisfactory in a strong electromagnetic eld.

●This product is a precision device. Do not drop or otherwise subject to shock. Risk

of product damage.

●Never attempt to disassemble, repair, or modify the product.

●When the product becomes unusable or unneeded, dispose of the product appro-

priately as industrial waste.

10

SPECIFICATIONS

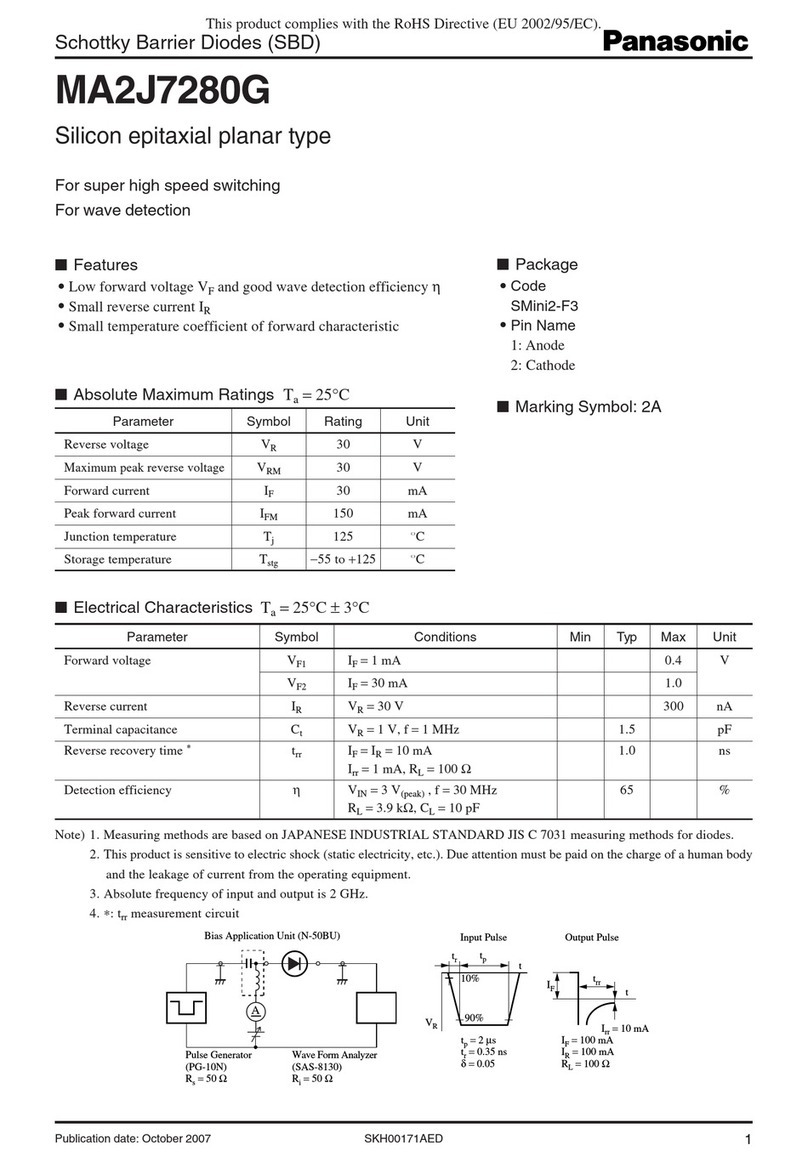

Type Master unit Slave unit

High performance type Wire-saving type

Model No. NPN output HG-TC101 HG-TC111 HG-TC113

PNP output HG-TC101-P HG-TC111-P

Applicable sensor head HG-T□

Number of connectable units Up to 15 slave units can be connected per master unit.

(When communication unit consolidated: up to 14 slave units)

Supply voltage 24V DC ±10%, including 0.5V ripple (P-P)

Current consumption (Note 2)

100mA or less (when sensor head is connected) (Note 2)

Analog output

(Switching type)

(Note 3)

Analog voltage

output

• Voltage output range: 1 to 5V / F.S. (default value)

• Alarm output: 5.2V

• Linearity: ±0.05% F.S.

• Output impedance: 100Ω MAX.

-

Analog current

output

•

Current output range: 4 to 20mA / F.S. (default value)

• Alarm output: 0mA

• Linearity: ±0.25% F.S.

• Load impedance: 250Ω MAX.

-

Control output

(

Output 1 / Output 2 / Output 3)

<NPN output type>

NPN open-collector transistor

• Maximum sink current: 50mA (Note 4)

•

Applied voltage: 30V DC or less (between output and 0V)

• Residual voltage: 1.5V or less (at 50mA sink current)

• Leakage current: 0.1mA or less

<PNP output type>

PNP open-collector transistor

• Maximum source current: 50mA (Note 4)

•

Applied voltage: 30V DC or less (between output and +V)

•

Residual voltage: 1.5V or less (at 50mA source current)

• Leakage current: 0.1mA or less

-

Short-circuit protection Incorporated (automatic reset type)

-

Decision output N.O./N.C. switching type

-

Alarm output Open when alarm

-

External input

(Input 1 / Input 2 / Input 3)

<NPN output type>

Non-contact input or NPN open-collector transistor

• Input condition

Invalid: +8V to +V DC or open

Valid: 0 to +1.2V DC

• Input impedance: Approx. 10kΩ

<PNP output type>

Non-contact input or PNP open-collector transistor

• Input condition

Invalid: 0 to +0.6V DC or open

Valid: +4V to +V DC

• Input impedance: Approx. 10kΩ

-

Trigger input Input time 2ms or more (ON)

-

Laser emission halt input Input time 20ms or more (ON)

-

Preset input Input time 20ms or more (ON)

-

Reset input Input time 20ms or more (ON)

-

Bank input A / B Input time 20ms or more (ON)

-

Sampling cycle 1 ms (standard sampling) / 0.5 ms (high-speed sampling)

Average count (Response time)

(Note 5)

1 time (2ms), 2 times (3ms), 4 times (5ms), 8 times (9ms), 16 times (17ms), 32 times (33ms), 64 times (65ms),

128 times (129ms), 256 times (257ms), 512 times (513ms), 1,024 times (1,025ms) switching type

Display resolution 1µm

Display range -199.999 to 199.999mm

Protection IP40 (IEC)

Pollution degree 2

Ambient temperature

-10 to +50°C (No dew condensation or icing allowed) (Note 4), Storage: -20 to +60°C

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Operating altitude 2,000m or less (Note 6)

Material Case: Polycarbonate, Cover: Polycarbonate, Switches: Polyacetal

Cable

0.2mm22-core (brown, blue

lead wires) / 0.15mm27-core

composite cable, 2m long

0.15mm27-core compos-

ite cable, 2m long

-

Weight (controller only) Approx. 140g Approx. 140g Approx. 60g

Notes: 1) Measured at a supply voltage of +24V DC and an ambient temperature of +20°C, unless otherwise indicated.

2) Current consumption does not include analog current output.

3) Linearity is the value to the digital measurement value based on the F.S. = 16mA when analog current is out-

put or the F.S. = 4V when analog voltage is output.

4) When slave units are connected to the master unit, the maximum sink current / source current of the control

output and ambient temperature vary depending on the number of connected slave units as shown below.

Number of connected slave units

Maximum sink current / source

current of control output

Ambient temperature

When communica-

tion unit consolidated

1 to 7 units 1 to 6 units 20mA -10 to +45°C

8 to 15 units 7 to 14 units 10mA

5) Average count (response time) gures have been calculated based on a sampling cycle of 1ms (standard

sampling). Response time varies if the sampling cycle is set to 0.5ms (high-speed sampling). Refer to the

“HG-T Series User’s Manual”.

6) Do not use or store in an environment pressurized to atmospheric pressure or higher at an altitude of 0m.

11

ERROR DISPLAY

Error

Display

Description Action

E100

Both NPN output types and PNP output types are connected.

Connect only units of the same output type.

E110 Number of connectable units exceeded. Connect no more than 15 slave units per master unit.

(When communication unit consolidated: up to 14 slave units)

E120

E130 Cannot communicate between controllers.

Switch OFF the power, make sure the controllers are

connected correctly, and then switch ON the power again.

E140

The calculation function is valid but no slave units are connected.

Change calculation mode to OFF.

E150 The calculation function is valid but an insufficient

number of slave units are connected.

Change calculation mode to OFF, or change the calcu-

lation application selection setting.

E160 The saved number of connected units does not match

the actual number of connected units.

Set the number of connected units check function to

OFF.

E170

The copy function was executed using the master

unit, but the copy operation does not start due to ab-

normal operation of the slave unit.

Switch the power OFF and switch it back ON again,

and then check if the slave unit is operating properly.

E180 Cannot communicate between controllers.

Switch OFF the power, make sure the controllers are con-

nected correctly, and then switch ON the power again.

E200

• Sensor head not connected.

• Broken wire in sensor head connection cable.

• Sensor head failure.

• Sensor head other than the HG-T series is con-

nected.

• Check if the sensor head is correctly connected.

• Check if there is a broken wire in the sensor head

connection cable. If there is a broken wire in the

sensor head connection cable, replace the cable.

• Replace the sensor head.

• Connect HG-T series sensor head.

E230

Paired sensor heads are both beam emitters or both beam receivers.

Check the connected sensor heads.

E240 Beam emitter abnormality Replace the sensor head.

E500 Unable to preset by external input.

Check if the power just been switched on or reset has

just been input, or if a display value is outside the dis-

play upper/lower limit or an alarm has occurred.

E510 Beam alignment function was used while the laser

emission halt input was ON.

Turn the laser emission halt input OFF, and then align

the beam axis.

E600 Unable to write to the EEPROM of the controller. • Switch the power OFF then ON, and execute initial-

ization of the controller from setting mode.

• If the controller does not recover after the above, it

is possible that the EEPROM write count is over

1 million. Replace the controller.

E610 Unable to read from the EEPROM of the controller.

E620 The EEPROM of the controller write count is over the

service life of 1 million.

E630 Unable to write to or read from the EEPROM of the

sensor head or beam receiver. • Switch the power OFF then on, and execute initial-

ization of the controller from setting mode.

• If the problem cannot be corrected by the above ac-

tion, please contact our company.

E640 Unable to write to or read from the non-volatile mem-

ory of the sensor head or beam emitter.

E700 The detection output load has short-circuited and ex-

cessive current is owing. Switch OFF the power and check the load.

E900

E910

E911

E912

E920

An error has occurred in the internal controller. Switch the power OFF then ON, and execute initializa-

tion of the controller from setting mode.

https://panasonic.net/id/pidsx/global

Overseas Sales Division (Head Ofce)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-568-33-7861 FAX: +81-568-33-8591

For sales network, please visit our website.

PRINTED IN JAPAN © Panasonic Industrial Devices SUNX Co., Ltd. 2018