WARNING

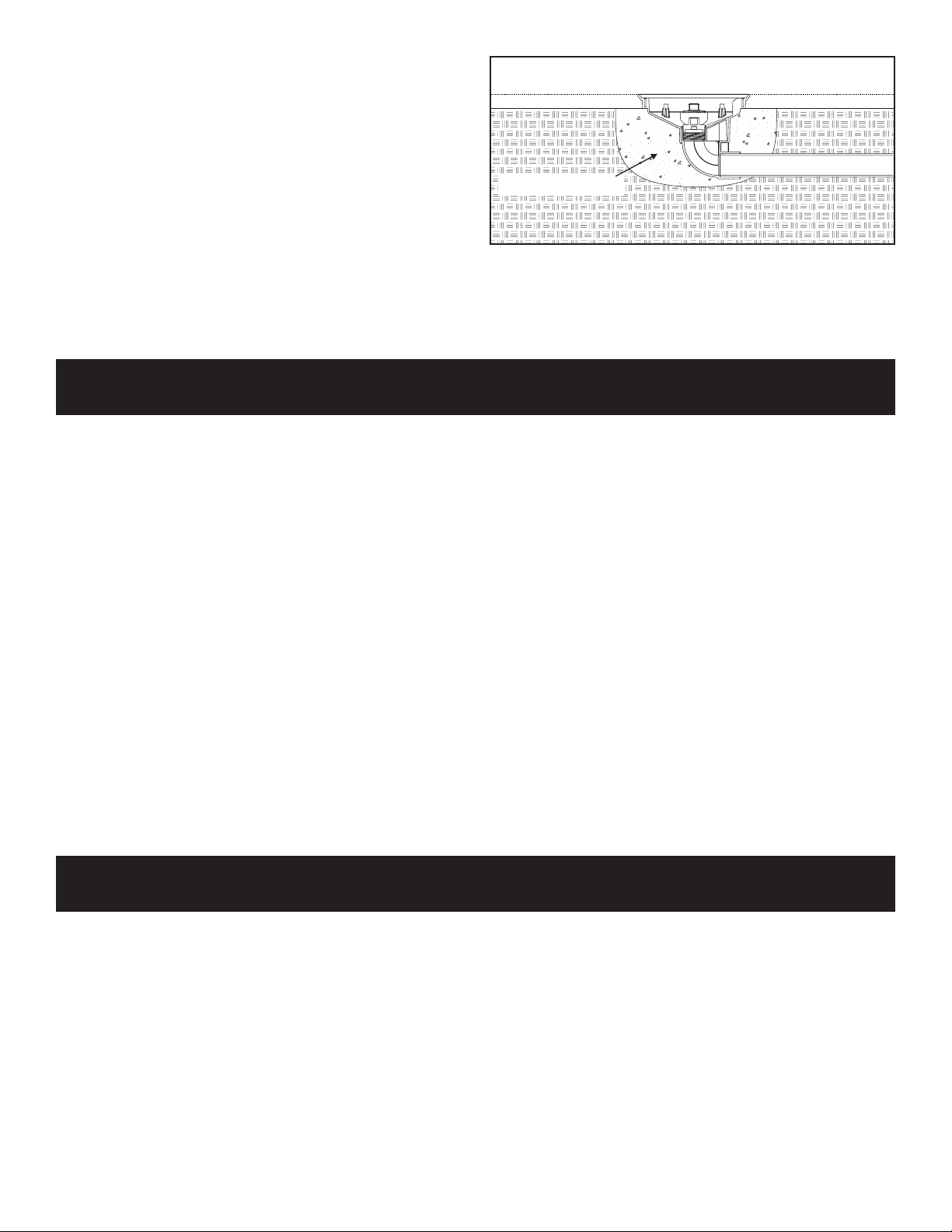

THIS P L MAY HAVE VENT TUBES AS A LAYER F ENTRAPMENT ADV IDANCE N THE SUCTI N UTLETS!

IF A VENT TUBE IS INSTALLED N THIS SYSTEM ATTACH THE ENCL SED WARNING LABELS T THE VENT

PIPE AND C NTR L PANEL AS INSTRUCTED N PAGE 9 F THIS MANUAL. IF THIS P L HAS BEEN

WINTERIZED THE VENT MUST BE INSPECTED WHEN STARTING THE P L F R THE SEAS N. REM VE THE PLUG FR M

THE ATM SPHERIC VENT PIPE BEF RE ENERGIZING THE P L PUMP(S)! TEST THE VENT BY BL CKING THE DRAIN.

AIR SH ULD ENTER THE PIPE AND CAUSE THE PUMP T CAVITATE RELEASING THE SUCTI N N THE DRAIN BL CK.

Suction can pose a serious hazard to swimmers just as electricity can be a hazard. Both are important for proper water

filtration and both must be treated with respect. Suction safety begins with a professional design that includes a quality

suction system installed by a certified contractor.

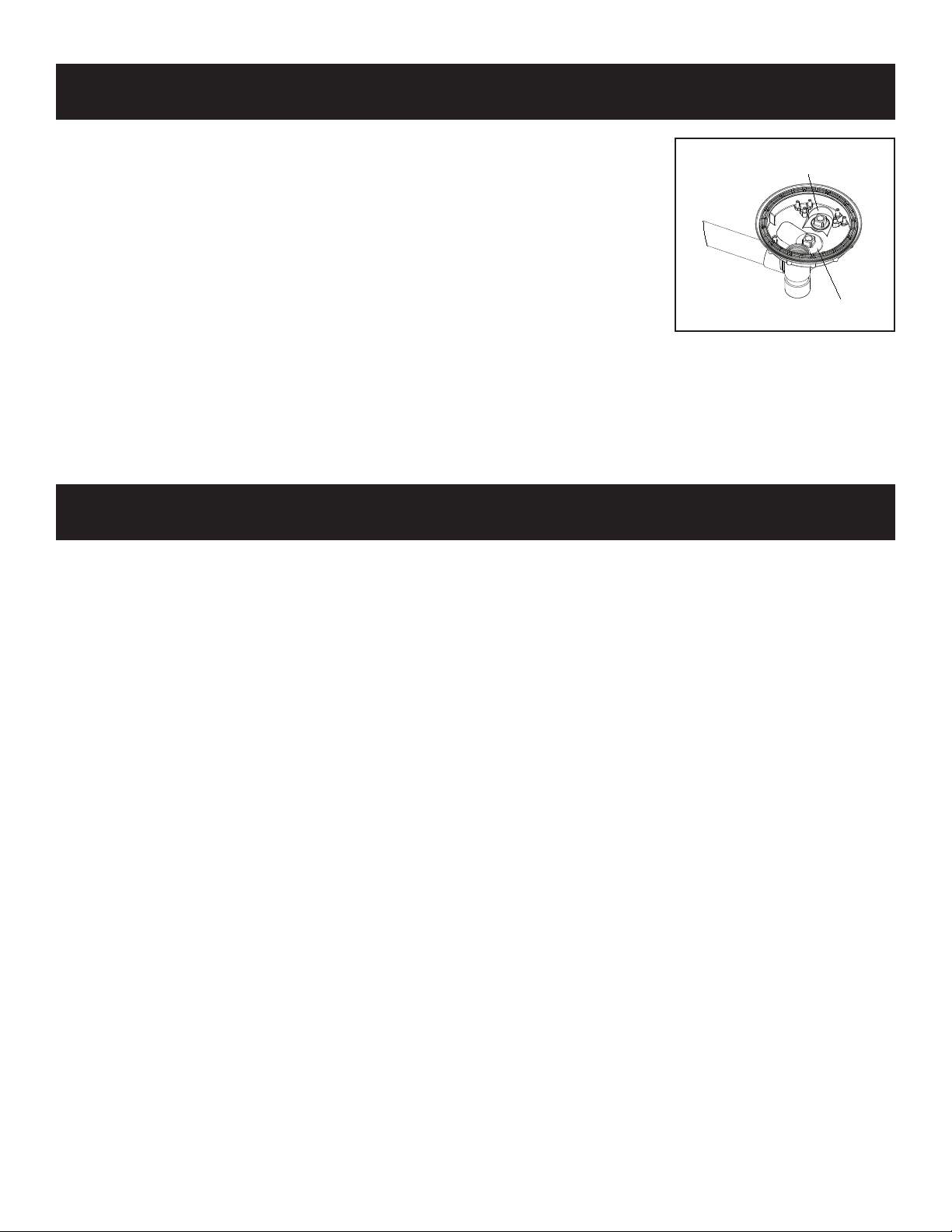

The MDX² Anti-Entrapment Debris Drain is only available to certified contractors for the same reason certified

electricians are required to connect filtration pumps to public utilities; both require proper training and certification to

assure no hidden hazards are built into the project.

Certified builders will address the following issues when designing and installing a proper filtration system:

• Properly bond-grounded pumps, time clocks, switches and any other metal in or near water. This is required to

address Electrical Shock azards.

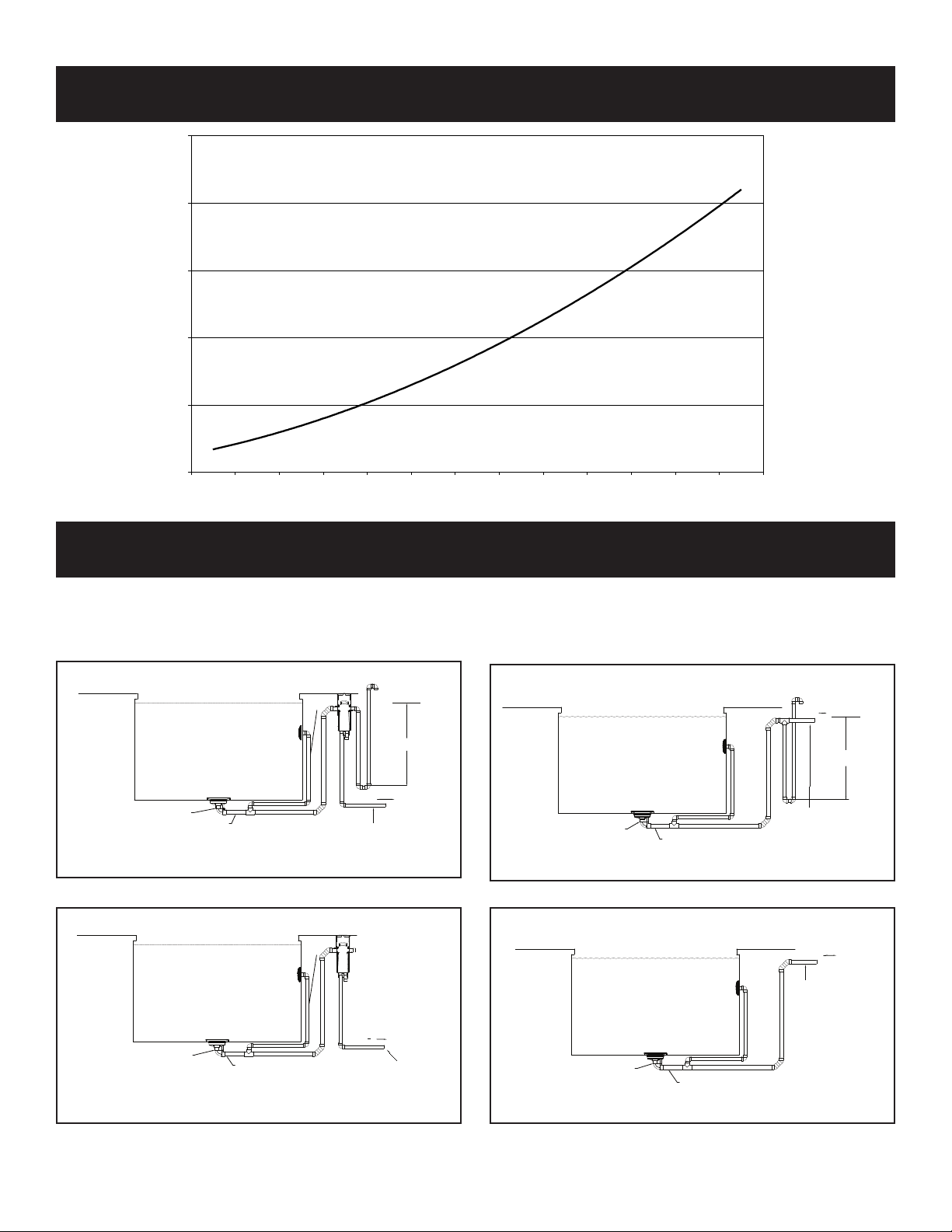

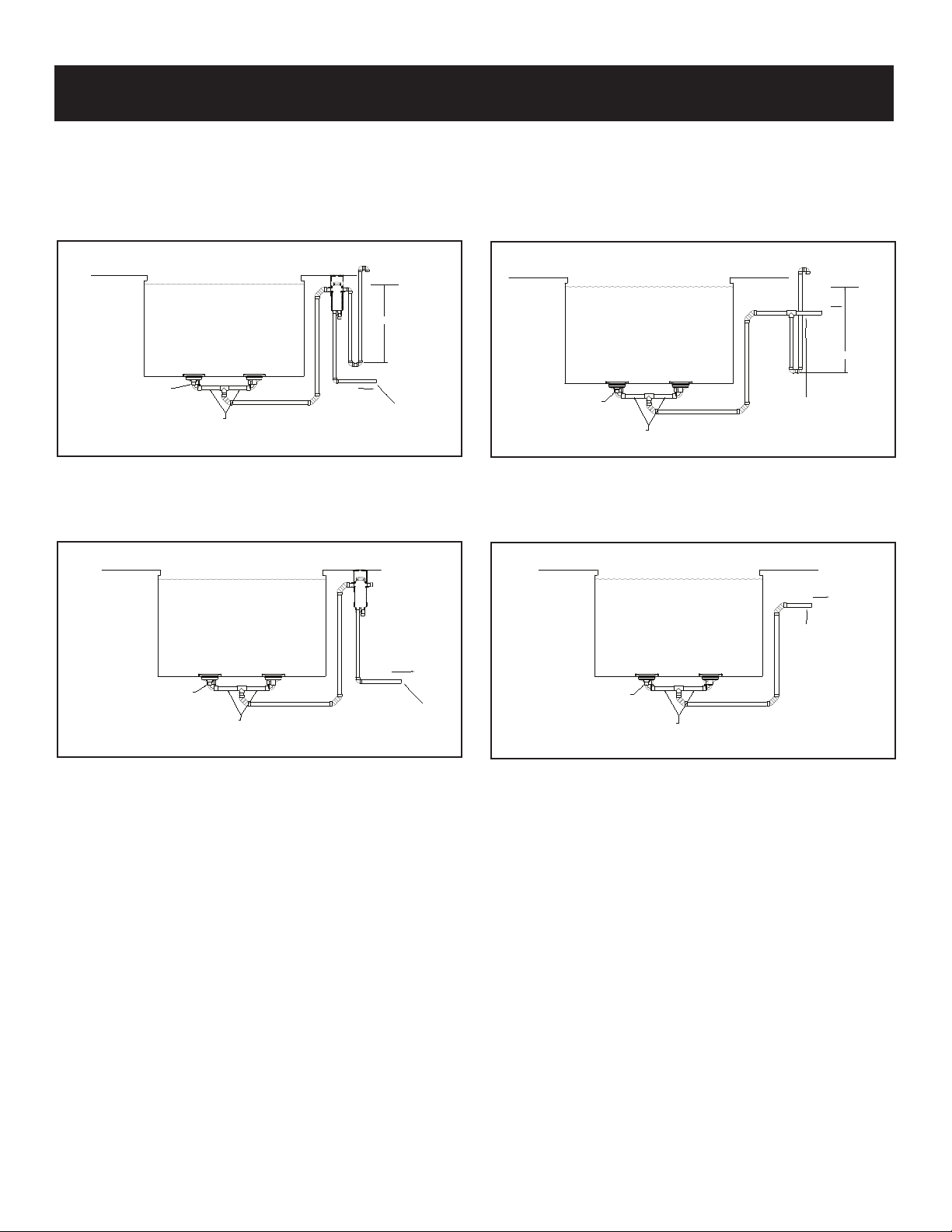

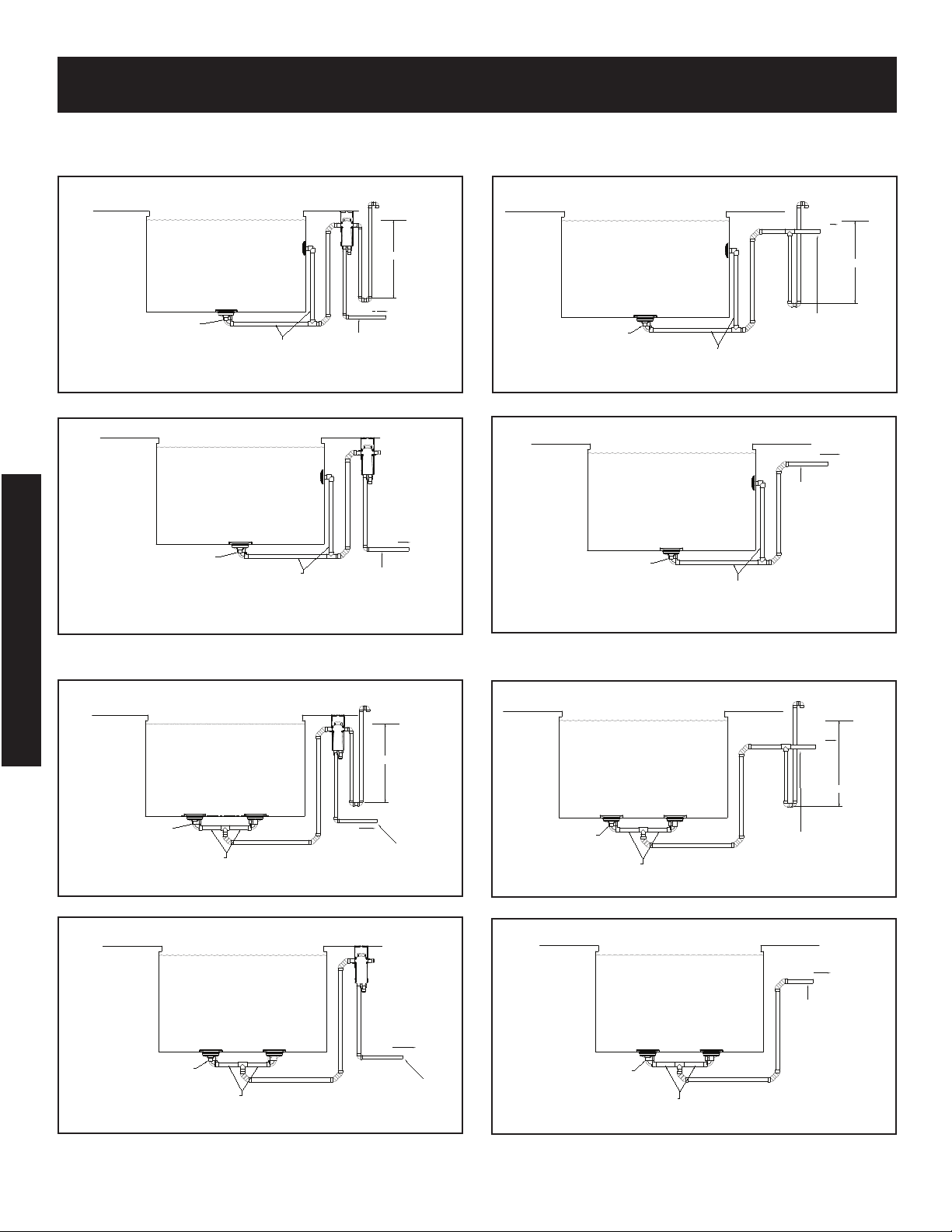

• Design the suction piping so there are no single-point suction hazards; single-point suction (one drain) is a leading

cause of Body Suction Entrapment azards. Note: your certified builder has many effective options for addressing

this hazard; they may include dual-drain systems, like MDX², skimmers, gutters, negative edge features and many

more products and piping designs known to professionals.

• Install ASME A112.19.8 - 2007 listed drains, suction covers and debris removal systems. This is the ONLY

approved option for preventing air Entrapment azards, the leading cause of suction related injuries.

• Design and install an effective circulation system (including optional cleaning systems), to direct filtered water to

all areas and interior surfaces. NOTE: Suction fittings can NOT clean or direct filtered water for proper sanitation;

that can only be done on the pressure (return) side of the filtration system.

While suction injuries are extremely rare, drowning and diving injuries are far too common and there is little your

certified builder can do to eliminate these hazards. You must educate yourself and your guests. Below are some

important safety issues every swimmer must know and recognize.

•PREVENT DROWNING: Watch children at all times, no swimming alone.

•NO DIVING IN S ALLOW WATER: You can be permanently injured.

•PREVENT SUCTION ENTRAPMENT: Inspect suction covers before swimming, keep swimmers away from suction

fittings, protect long hair, don’t swim with loose clothing or large and dangling jewelry.

WARNING: MDX² and SDX must be installed in accordance with Paramount's written instruction manual, and in

conformity with applicable Federal, State, Local and Swimming pool industry building and safety codes.

WARNING

KN WN DR WNING HAZARD.

D N T G NEAR THE SUCTI N FITTINGS R DRAINS F Y UR P L R SPA. Y UR HAIR R B DY

MAY BEC ME TRAPPED CAUSING PERMANENT INJURY R DR WNING.

D N T ENTER THE P L R SPA IF SUCTI N FITTINGS R DRAIN C VERS ARE L SE, BR KEN, R

MISSING. INSPECT SUCTI N FITTING INCLUDING FASTENERS F R DAMAGE N TAMPERING BEF RE

EACH USE F THIS FACILITY.

WARNING

RISK F SEVERE INJURY R DR WNING IF SUCTI N SYSTEMS ARE N T INSTALLED PR PERLY!

N TICE T WNER:

READ, F LL W, AND KEEP THESE SAFETY INSTRUCTI NS F R FUTURE REFERENCE.

IMP RTANT N TICES: PLEASE READ

© 2006, Paramount Pool & Spa Systems

For technical assistance call 1-800-621-5886 or contact your regional representative.