02-0040ME July2013© 2013 Parker Hannin Corporation | Autoclave Engineers is a registered trademark of the Parker Hannin Corporation

Parker Hannin Manufacturing Ltd.

Instrumentation Products Division, Europe

Industrial Estate Whitemill

Wexford, Republic of Ireland

PH: 353 53 914 1566

FAX: 353 53 914 1582

Instrumentation Products Division

Autoclave Engineers Operation

8325 Hessinger Drive

Erie, Pennsylvania 16509-4679 USA

PH: 814-860-5700 FAX: 814-860-5811

www.autoclave.com

WARNING

FAILURE, IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannin Corporation, its subsidiaries and authorized distributors provide product and/or system options for further investigation by users having technical

expertise. It is important that you analyze all aspects of your application and review the information concerning the product or system in the current product catalog. Due to the variety of operating conditions

and applications for these products or systems, the user, through its own analysis and testing, is solely responsible for making the nal selection of the products and systems and assuring that all performance,

safety and warning requirements of the application are met. The products described herein, including without limitation, product features, specications, designs, availability and pricing, are subject to change by

Parker Hannin Corporation and its subsidiaries at any time without notice.

Offer of Sale

The items described in this document are available for sale by Parker Hannin Corporation, its subsidiaries or its authorized distributors. Any sale contract entered by Parker will be governed by the provisions

stated in Parker's standard terms and conditions of sale (copy available upon request).

ISO-9001 Certied

Section 5.0

Assembly

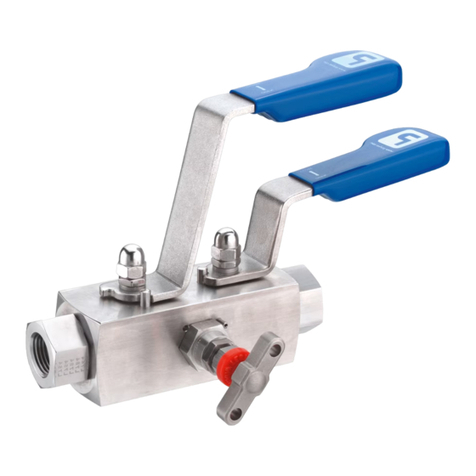

General Assembly Procedure 1/4” Port 2-Way Ball

Valve

1. Drop bottom bearing into center opening of the body.

2. Using packing gland, delicately slide the stem seal and

backup onto the upper shoulder of stem. Lubricate seal and ball

surface with o-ring grease.

3. Lubricate the top of the upper shoulder of stem with Jet

Lube and slip the thrust washer onto the stem.

4. Lubricate the top of the thrust washer and packing gland

threads with Jet Lube and slip the packing gland onto the stem.

5. With the stem at to the left, screw the packing gland/stem

assembly into the body center opening until the opening of the

ball is aligned properly. Back packing gland out one complete

turn.

6. Assemble locknuts onto seat glands.

7. Install o-rings onto the seat glands and lube the o-rings

with grease.

8. Press seats into seat retainers and press these seat assem-

blies rmly onto the nose of the seat glands.

9. Lubricate seat gland threads with Jet Lube and insert seat

glands into body hand tight on both sides.

10. Keeping ball in full open position, pre-torque seat glands

to 150 in. lb. (17 Nm) in 25 in. lb. (2.8 Nm) alternating incre-

ments.

11. Back seat glands off on both sides and retorque to 75 in. lb.

(8.5 Nm) in 25 in. lb. (2.8 Nm) alternating increments.

12. While holding seat glands secure with a wrench, tighten

seat gland locknuts to the valve body.

13. Hand tighten packing gland.

14. Using a spanner wrench, tighten the locking piece to the

valve body.

15. Position stopping device loosely on top of packing gland

and attach the handle onto the at of the stem. Turn stopping

device clockwise until it hits the handle hub. Tighten the (2) set

screws on the stopping device onto the packing gland

.

Section 3.0

Precautions

Hold the seat glands with a wrench when tightening or

loosening the tubing connections.

DO NOT OPERATE THE VALVE WITH

MORE THAN 75 IN. LBS (8.5 Nm)

APPLIED TO THE SEAT GLANDS.

Ball valves can trap pressurized media inside the valve.

Relieve this pressure by turning the handle to the “half-

open” position before disassembling the valve.

Section 4.0

Maintenance

Routine maintenance consists of tightening the seat

glands periodically to compensate for seat wear. With no

pressure in the valve, use the

following procedures:

4.1 Seat Glands

4.1.1 Remove lock device from seat glands

4.1.2 While holding the seat glands and the body

secure, loosen the tubing connections

4.1.3 With the handle in the “Full Open ” position,

gradually tighten the glands alternating from one gland to

the other in increments of 25 in. lbs. (2.8 Nm) until 75 in.

lbs. (8.5 Nm) has been reached.

Do Not Apply More Than 75 In. Lbs. (8.5 Nm)

4.1.4 While holding seat gland secure with a wrench,

tighten seat gland locknuts to the valve body.