EN | User Manual

AKM 1-8 1

Index

Machine passport 3

General information 4

Manufacturer’s details .............................................................................................................. 4

Details on the dryer................................................................................................................... 4

About these operating instructions........................................................................................... 5

For your own safety 6

General safety notes................................................................................................................. 6

Intended use of the adsorber.................................................................................................... 7

Signs and hazard areas on the adsorber ................................................................................. 8

Transportation, installation and storage 10

Information on transportation packaging................................................................................ 10

What to do in the case of transport damage occurring? ........................................................ 10

Transporting and installing the adsorber................................................................................. 11

Storing the adsorber ............................................................................................................. 13

Technical product description 14

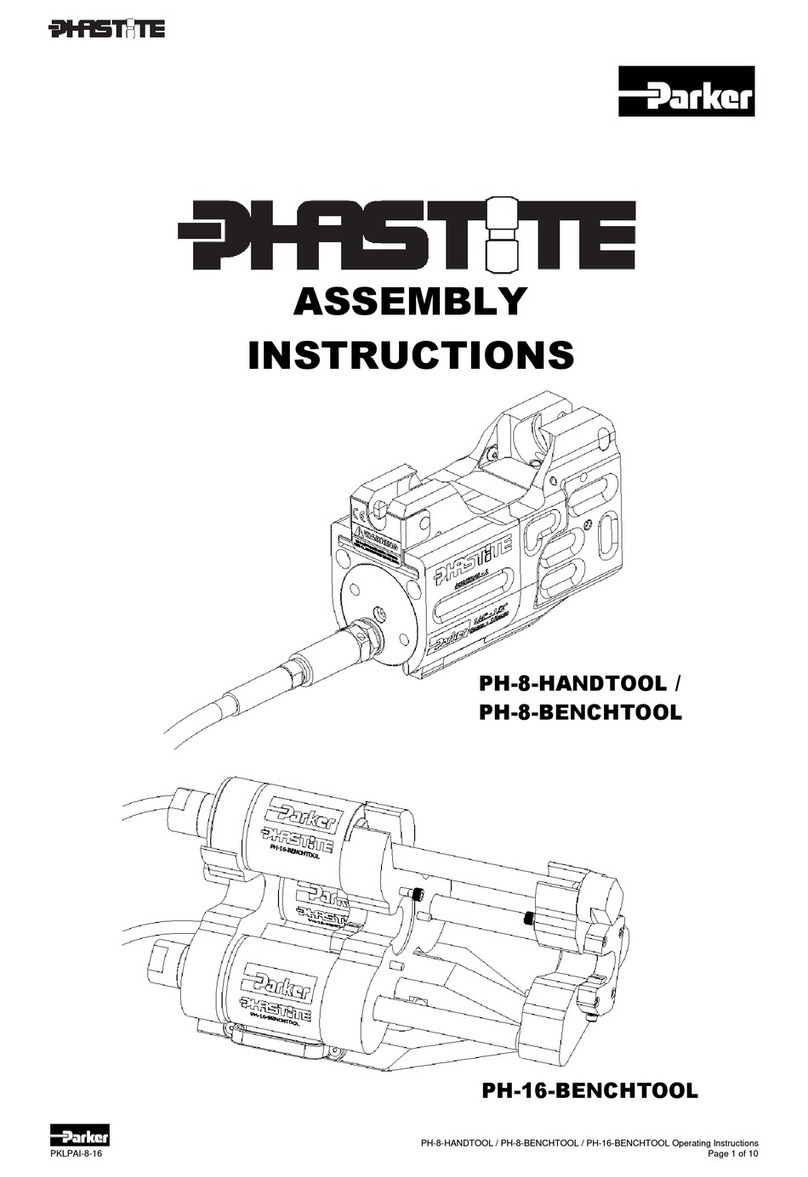

Summary drawing................................................................................................................... 14

Function description ............................................................................................................... 14

Installation 15

Preconditions for installation .................................................................................................. 15

Connect piping ....................................................................................................................... 16

Start-up 17

Requirements for initial start-up ............................................................................................. 17

Overview of operating and control elements .......................................................................... 18

Emergency shutdown .............................................................................................................18

Start up adsorber.................................................................................................................... 18

Monitoring adsorber operation 20

Shutdown and restart adsorber 21

Restart .................................................................................................................................... 22

Maintenance and repair of the adsorber 23

Notes on maintenance............................................................................................................ 23

Regular maintenance intervals................................................................................................ 24

Daily maintenance tasks ......................................................................................................... 25

Monthly maintenance tasks .................................................................................................... 25

Maintenance work to be completed every 12 months............................................................ 29

Identify and eliminate faults 31

Summary of faults................................................................................................................... 31

Annex with technical documentation 32

Technical data......................................................................................................................... 33

Replacement and wear part list .............................................................................................. 34

Installation on oor ................................................................................................................. 39