MX80L Series Product Manual

5 Automation

Parker Hannifin Corporation

Irwin, Pennsylvania

Chapter 1 - Introducon

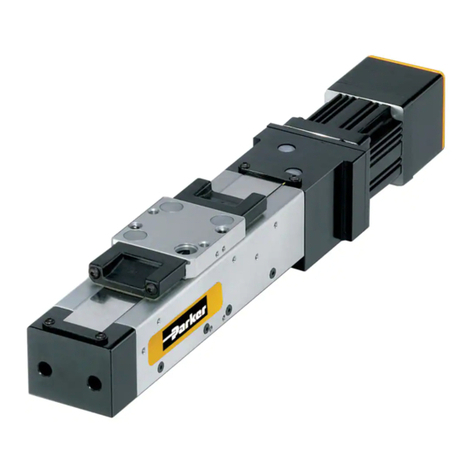

MX80L Posioner

Although the MX80L is small in size and weight, it is large on performance and reliability. All key components are integral to the unit -

residing within the body of the stage to provide a clean looking, reliable, unobstructed package. At the heart of the MX80L is an inno-

vave non-contact linear servo motor (patent pending). This direct drive motor has been opmized for force, speed, and acceleraon,

to deliver outstanding performance and response. A high precision non-contact linear encoder provides sub-micron resoluon and

repeatability. Selectable resoluons range from 10 nanometers to 5 microns. Precision ground “zero cage creep” crossed roller bear-

ing sets provide extremely smooth - precise linear translaon. Travel limit and home sensors are conveniently designed into the unit

for easy adjustment over the enre travel of the stage. Although there are no moving cables, 1 or 3 meters of hi-ex cabling depend-

ing on conguraon opon is included and wired directly into the units. This hi-ex cabling addresses cable exing concerns associat-

ed with the second or third axis in mul-axis system.

Product Description

Unpacking

Carefully remove the posioner from the shipping container and inspect the unit for any evidence of shipping damage. Report any

damage immediately to your local authorized distributor. Please save the shipping container for damage inspecon or future

transportaon.

Incorrect handling of the posioner may adversely aect the performance of the unit in its applicaon. Please observe the follow-

ing guidelines for handling and mounng of your new posioner:

• Product may be heavy. Standard handling and liing pracces should be employed.

• DO NOT allow the posioner to drop onto the mounng surface. Dropping the posioner can generate impact loads that may

result in at spots on bearing surfaces or misalignment of drive components.

• DO NOT drill holes into the posioner. Drilling holes into the posioner can generate parcles and machining forces that may

eect the operaon of the posioner. Parker will drill holes if necessary; contact your local authorized distributor.

• DO NOT subject the unit to impact loads such as hammering, riveng, etc. Impacts loads generated by hammering or riveng

may result in at spots on bearing surfaces or misalignment of drive components.

• DO NOT li the posioner by cables or cable management system. Liing posioner by cables or cable management system

may eect electrical connecons and/or cable management assembly. The unit should be lied by the base structure only.

• DO NOT expose posioner to mist, spray or submersion in liquids.

• DO NOT disassemble posioner. Unauthorized adjustments may alter the posioner’s specicaons and void the product war-

ranty.