Pedigo P-2010-S Blanket Warming Cabinet Operation and Care Manual

6

CONTROL FEATURES

THERMOSTAT AND PILOT LIGHT SEQUENCE

Whenever the thermostat is turned "ON", the heat indicator

light will indicate the power ON/OFF condition of the

heating cable, and consequently, the cycling of the cabinet

as it maintains the set cavity temperature. If the pilot light

does not illuminate after normal start-up, the main power

source, thermostat, and/or pilot light must be checked. If

the warming cabinet does not hold the temperature as set,

the calibration of the thermostat must be checked. If the

warming cabinet fails to heat or heats continuously with the

thermostat "OFF", the thermostat must be initially checked

for proper operation. If these items are checked and found

to be in order, a continuity and resistance check of the

heating cable should be made.

SEE WIRING DIAGRAM.

THERMOSTAT ACCURACY

The thermostat is precision calibrated at the factory.

Normally, no adjustment or recalibration is necessary unless

the thermostat has been mishandled in transit, changed, or

abused while in service. A thermostat with a sensing bulb

operates on hydraulic pressure, consequently, any bending

of the bulb results in a change in its volume, and alters the

accuracy of the thermostat calibration.

A thermostat should be checked or recalibrated by placing a

quality, thermal indicator at the center of an empty holding

cavity. DO NOT CALIBRATE WITH ANY BLANKETS IN

THE CABINET. The thermostat should be set, and should

be allowed to stabilize at that setting for a minimum of one

hour. Following temperature stabilization, the center of the

thermal swing of the air temperature within the cabinet

should approximately coincide with the thermostat setting.

If calibration is necessary, the calibration screw should be

adjusted with great care. The calibration screw of the

thermostat is located in the thermostat dial shaft. With the

shaft held stationary, a minute, clockwise motion of the

calibration screw appreciably lowers the thermostat setting.

A reverse, or counter-clockwise motion appreciably raises

the thermostat setting. After achieving the desired cycling

of the thermostat, the calibration screw must be sealed.

Place a few drops of enamel sealant directly on the

calibration screw. [Red nail polish or equivalents

acceptable.]

OPERATIONAL PROCEDURES

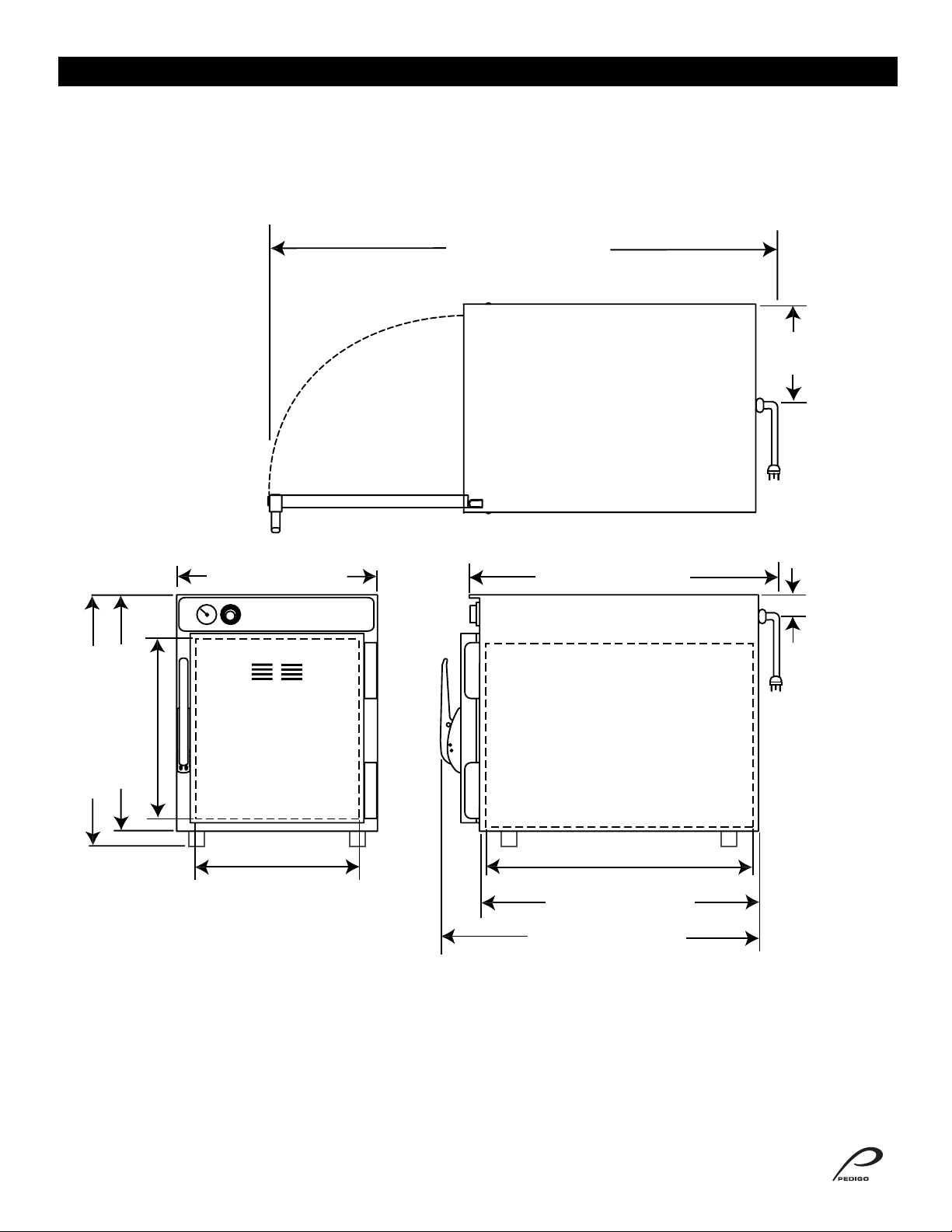

1. The appliance should be plugged into a hospital

grade, NEMA 5-15P receptacle. The unit requires

1"clearance on sides, back, and bottom.

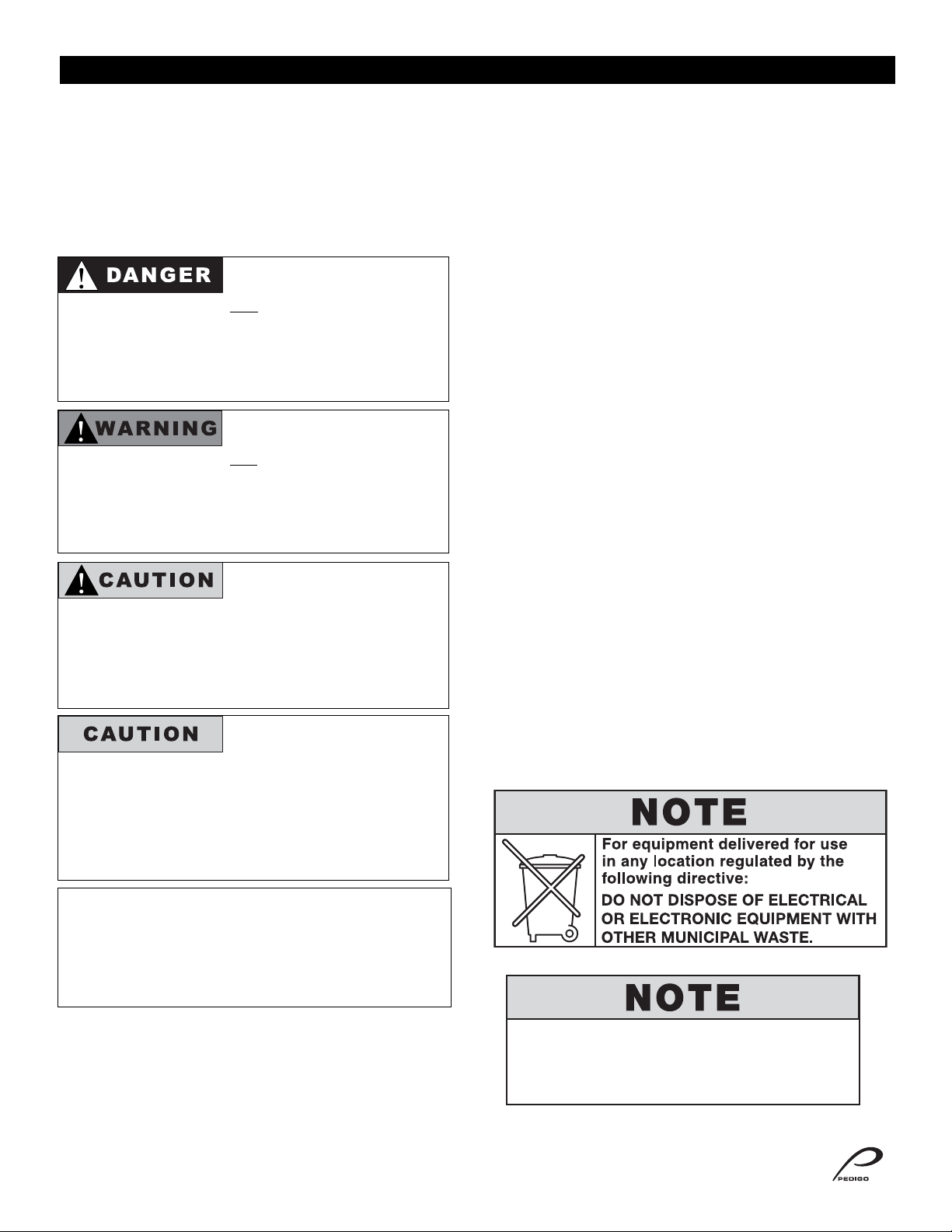

2. Turn on the power circuit breaker

switch, which is located at the back

of the appliance. It is a rocker-type

switch with international ON (I) and

OFF (O) markings.

3. PREHEAT AT 200°F (93°C).

When the thermostat is turned clockwise to an "ON"

position, the red indicator light will illuminate and will

remain lit as long as the unit is calling for heat. The red

indicator light will go "OUT" when the air temperature

inside the unit reaches the temperature set by the

operator. Verify the full preheated temperature with the

holding temperature gauge located on the control panel

of the cabinet.

4. LOAD THE CHAMBER WITH 100% COTTON

BLANKETS. DO NOT WARM SYNTHETIC BLEND

FABRICS OR ITEMS CONTAINING PLASTIC, RUBBER

OR METAL SNAPS, STUDS, HOOKS, ETC.

Check that the epoxy-coated blanket support assembly is

in place. This blanket support assembly MUST be used to

hold blankets. A full load of blankets will take 1-2 hours to

reach optimum temperature. Make certain the cabinet

door is securely closed after initial loading and following

each blanket removal.

Note: Do not block sensor by overloading cabinet

with blankets.

5. ROTATE LOAD OF BLANKETS DAILY.

Rotate the blankets at the bottom of the load to the top to

ensure equal usage. Failure to rotate blankets can cause

blankets to discolor.

Note: Avoid using flammable cabinet cleaning

agents, as well as blanket cleaning agents

that cause fabric to become brittle over time.

POWER

CIRCUIT BREAKER

SWITCH

CAUTION

DO NOT OVERLOAD CABINET.

BLANKETS MUST NOT EXCEED HEIGHT OF

SUPPORT ASSEMBLY. ALLOW 1" GAP BETWEEN

LOWER BLANKETS AND MIDDLE SHELF.

CAUTION

BLANKET SUPPORT ASSEMBLY AND SHELF

MUST BE USED WHEN WARMING BLANKETS.