Pedigo P-2030-S Blanket Warming Cabinet Operation and Care Manual

3

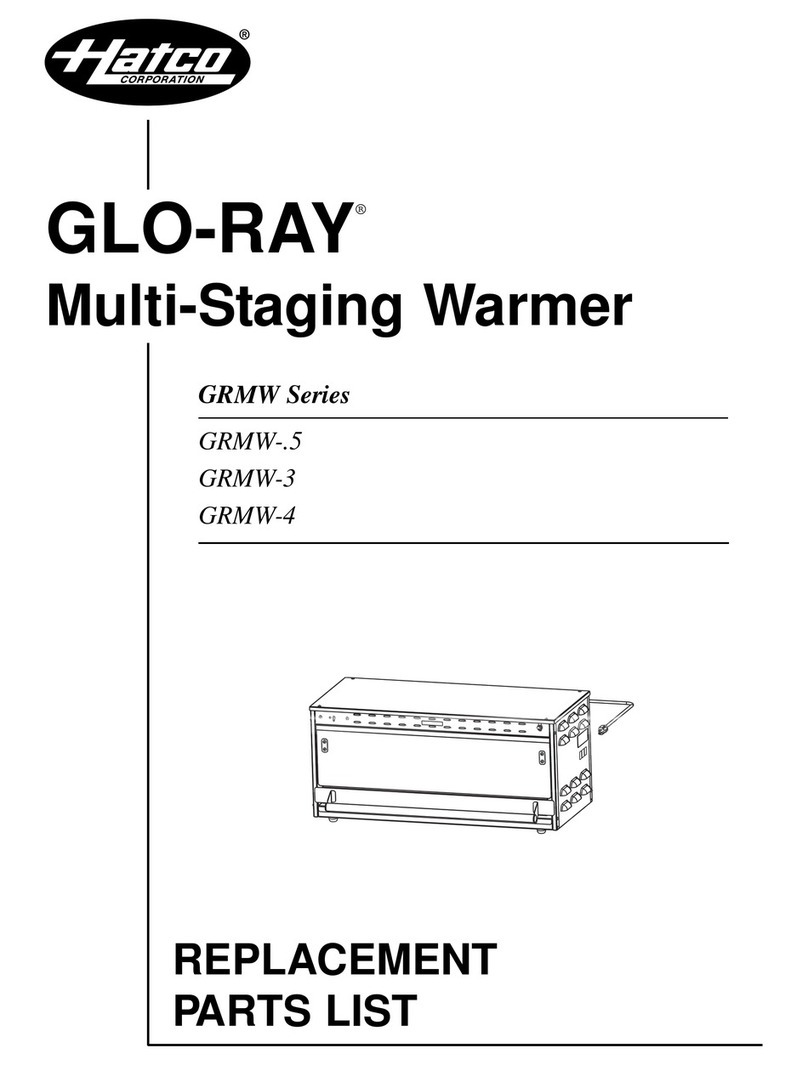

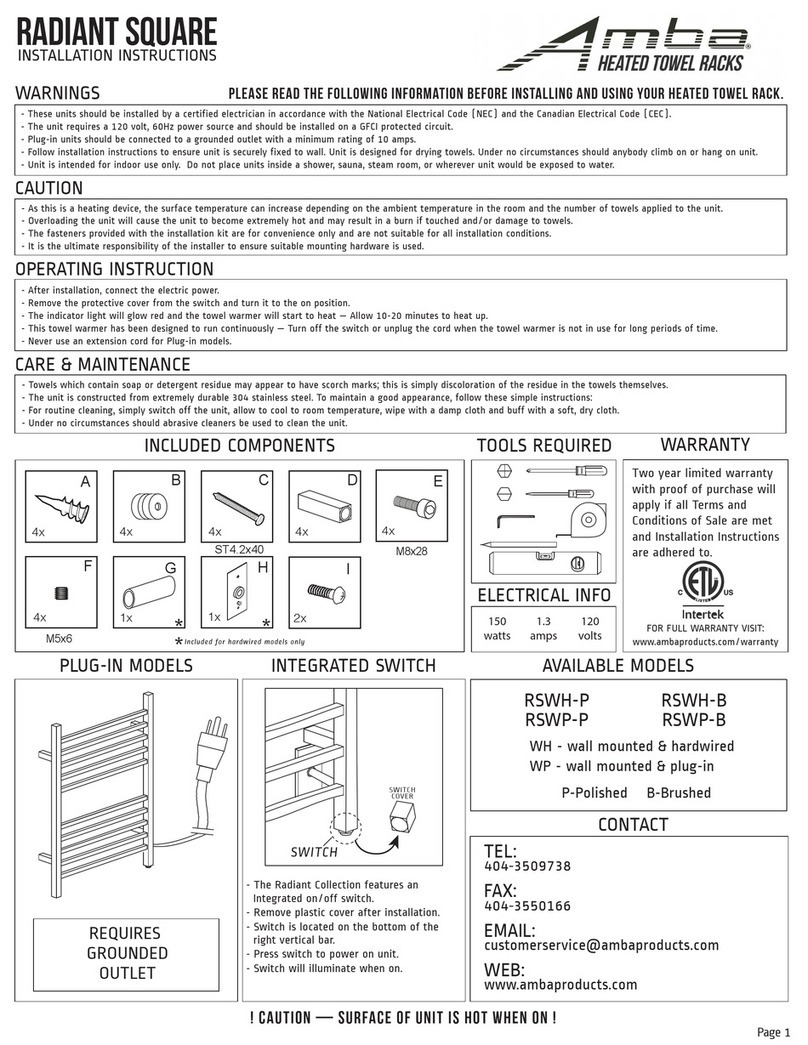

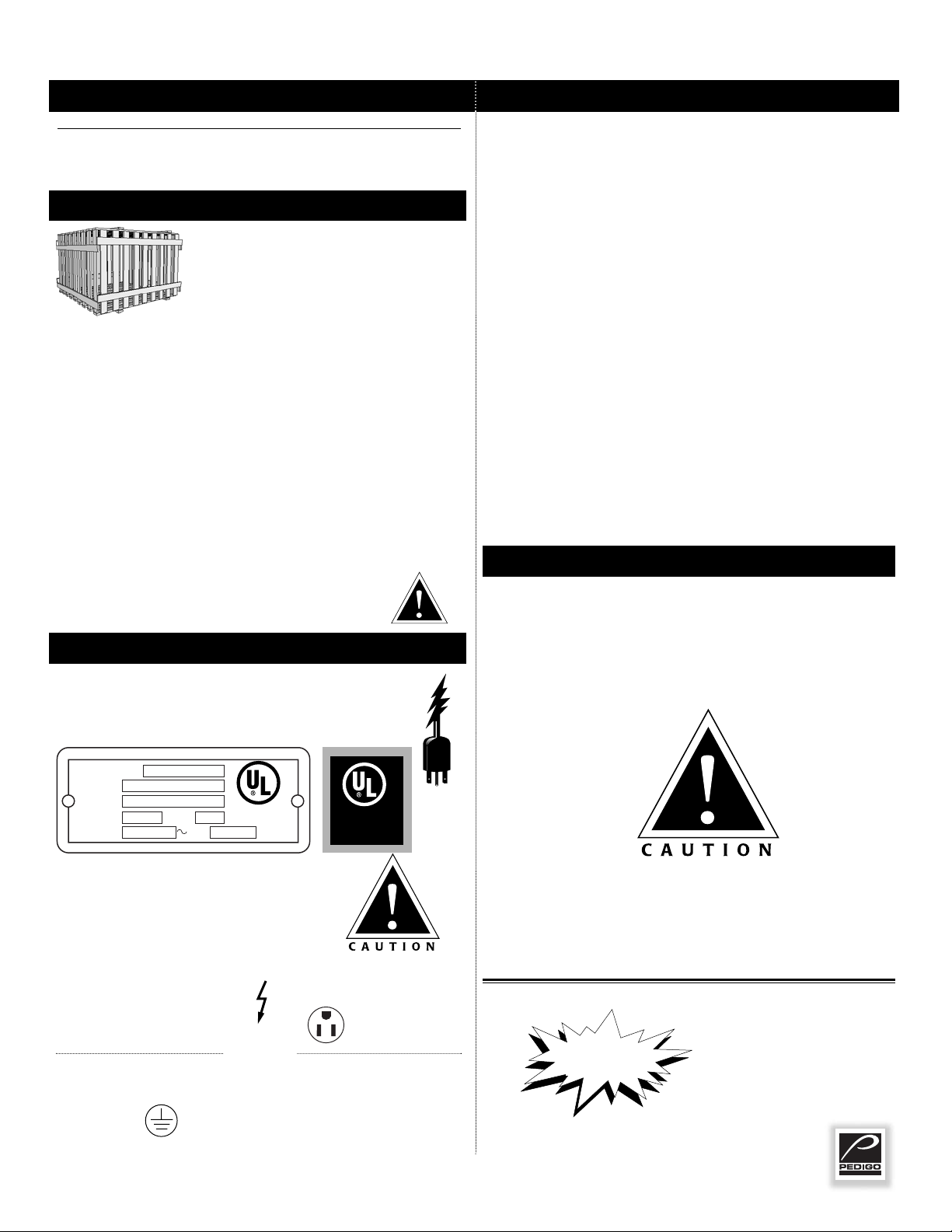

SET

prg

!

ERROR CODE

INDICATOR L.E.D.

HEAT

INDICATOR L.E.D.

CHAMBER

TEMPERATURE

L.E.D.

TEMPERATURE

SET

BUTTON

POWER

ON/OFF

ROCKER SWITCH

L.E.D.1 INCREASE / DECREASE

BUTTON

200

●

THERMOSTAT

"I" = "ON"

"●" = "OFF"

OPERATIONAL PROCEDURES

• L.E.D., Light Emitting Diode, referred to is an

electronic device providing illumination.

1. TURN POWER SWITCH ON.

The heat indicator L.E.D. will illuminate and remain

lit while the unit is calling for heat. The digital

display will indicate air temperature of the heated

compartment. The heat indicator L.E.D. will go out

when the air temperature inside the unit reaches the

temperature set-point on the electronic thermostat.

2. VIEW OR CHANGE SET-POINT.

A. Push the SET button once. The set-point value

(current set-point holding temperature) will be

displayed for 5 seconds. NOTE: Factory default

is 90°F (32°C).

B. The set-point value can be changed by pressing

and holding the SET button for at least 4

seconds. The programming mode becomes

active and the LED1 indicator will blink. Press

and hold the UP or DOWN arrow button to

change the value shown in the display. The value

can be stored either by pressing the SET button

or by waiting the exit time-out to expire

(approximately 15 seconds). The new set-point

value will flash three times to confirm. This value

will be retained until it is changed again. The

minimum set-point temperature is 90°F (32°C)

while the maximum set-point temperature is

200°F (93°C). Typical temperature settings are

around 160°F (71°C).

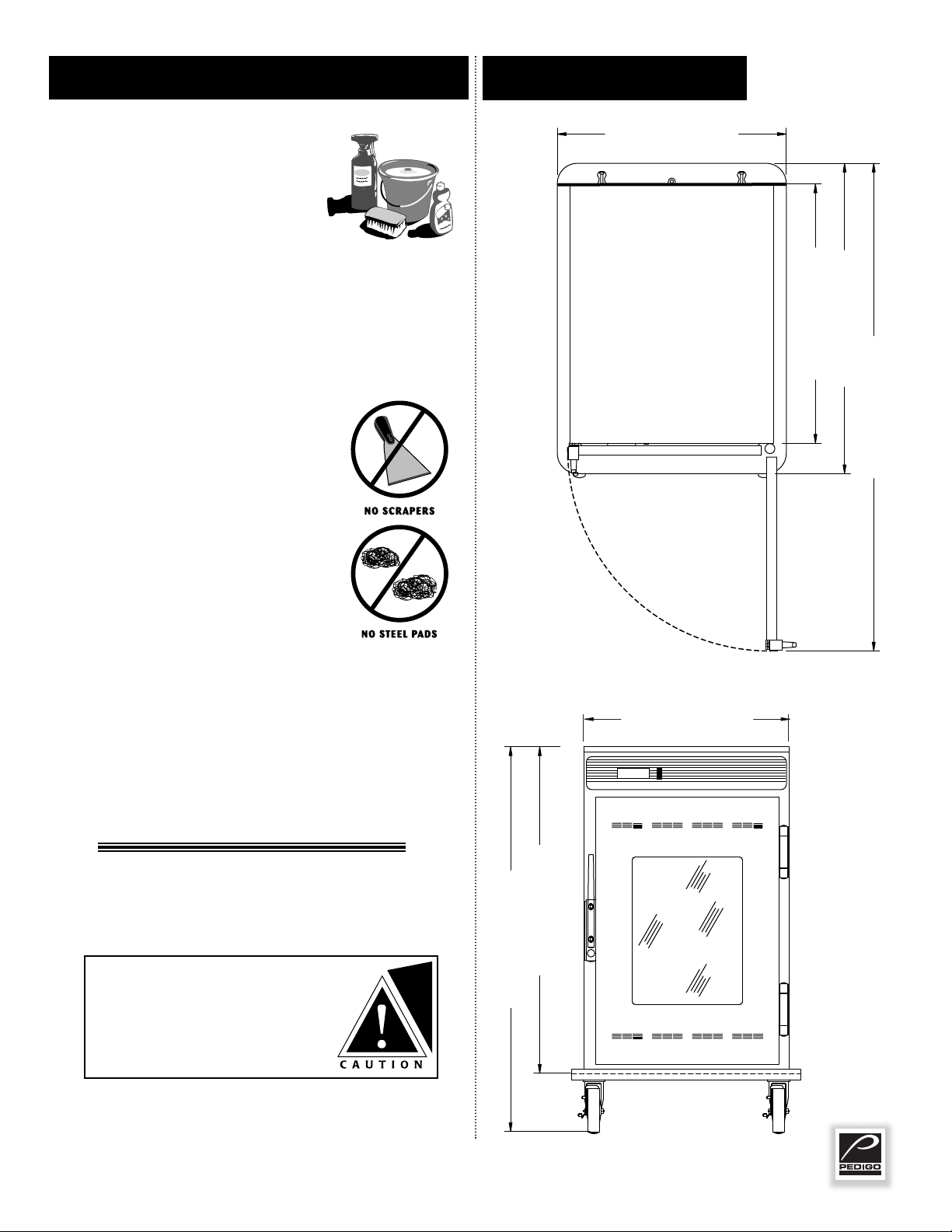

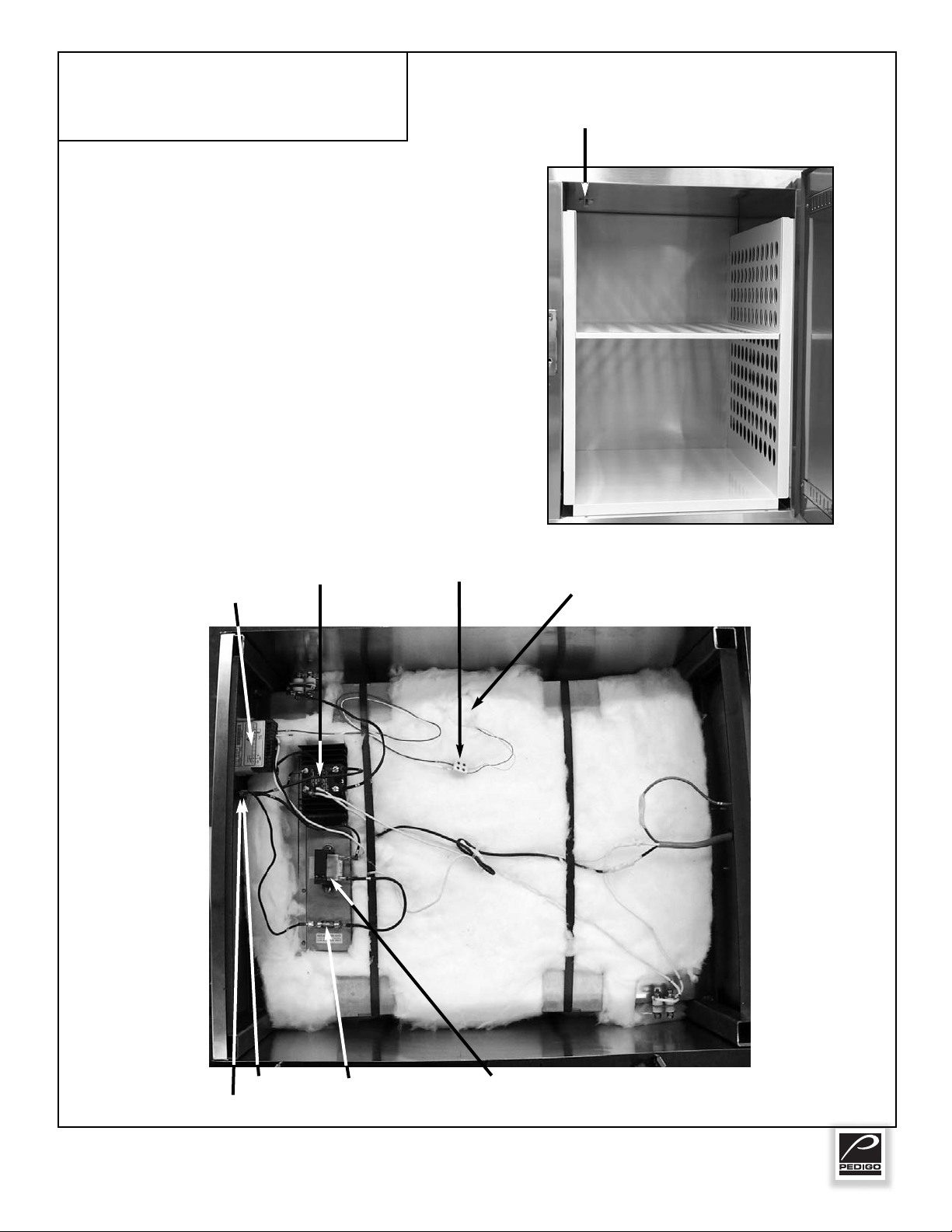

3. LOAD THE CABINET WITH BLANKETS.

Check that the epoxy-coated blanket support

assembly and shelf are in place. The warming

cabinet is designed to elevate blanket temperatures

to a level which will increase patient comfort.

Do not fill cabinet any closer than 2" from ceiling of

warming chamber (If sensor becomes blocked,

overheating could result.) A full load of blankets

will take several hours to reach optimum

temperature. Make certain the cabinet door is

securely closed after initial loading and following

each blanket removal.

DO NOT BLOCK SENSOR BY

OVERLOADING CABINET WITH

BLANKETS. OVERHEATING

COULD OCCUR.

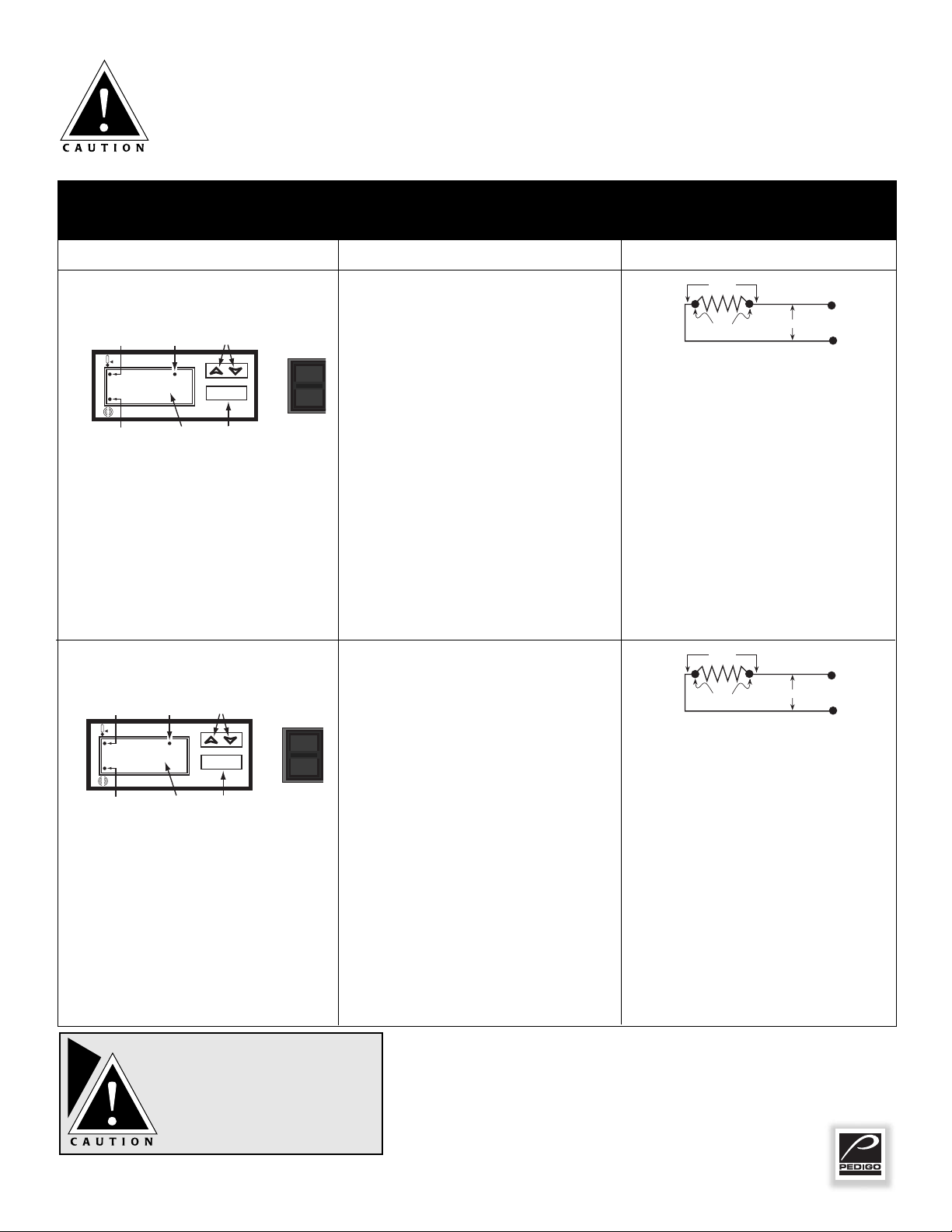

THERMOSTAT

and INDICATOR LIGHT SEQUENCE

Whenever the thermostat is turned “ON,” the heat

indicator L.E.D. will indicate the power “ON/OFF”

condition of the heating cable, and consequently, the

cycling of the cabinet as it maintains the set-point

cavity temperature. If the L.E.D. does not illuminate

after normal start-up, the main power source and

thermostat must be checked. If the warming cabinet

does not hold the temperature as set, the calibration of

the thermostat must be checked. If the warming

cabinet fails to heat with the L.E.D. illuminated, or

heats continuously with the L.E.D. of thermostat “OFF,”

unplug and call for service.

THERMOSTAT ACCURACY

The electronic thermostat is a precise instrument and

is designed to offer trouble-free service. If you suspect

the temperature inside the warming cabinet does not

match the temperature indicated on the digital display,

after stabilizing, follow the instructions listed below.

1. Check to make certain the power meets the

requirements of the appliance, voltage and current

rating as indicated on identification tag.

2. Verify the temperature inside the warming cabinet

with a quality thermal indicator.

A. With the exception of the metal shelves,

completely empty the warming cabinet.

B. Make certain the sensor, located inside the

warming cabinet at the left side of the ceiling,

is completely clean.

C. Suspend the thermal indicator in the center of

the warming cabinet.

D. Allow the temperature, set on the electronic

thermostat, to stabilize for a minimum of one

hour before comparing the digital display with

the reading on the thermal indicator.

DO NOT OPEN THE CABINET DOOR(S) DURING THE

TEMPERATURE STABILIZATION PERIOD.

If the reading on the thermal indicator does not match

the digital display within 10°F (6°C), contact Pedigo

for appropriate action.

CONTROLLER