Certificate

1.

1

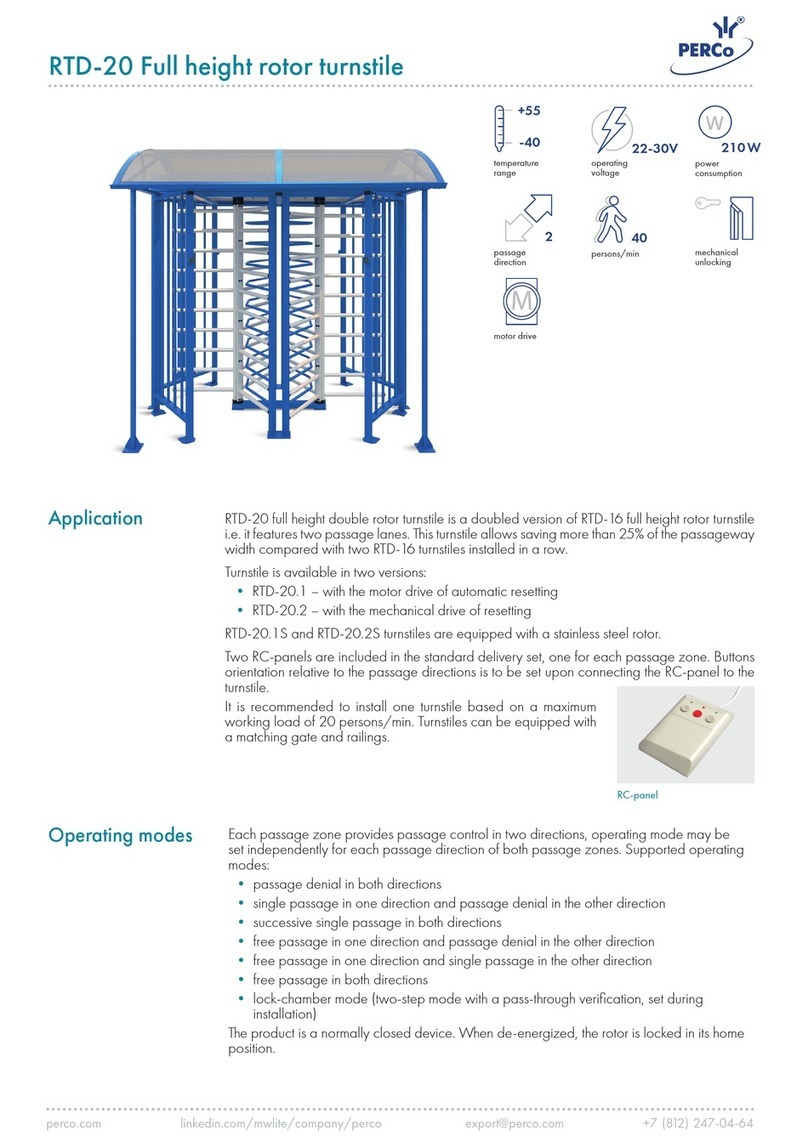

GENERAL DATA

1.1 Foundation frame RF01 0-01 (hereinafter – the frame) is designed to ease in-

stallation as well as achieve quality and precision in installation of full-height turnstiles of

RTD-15 series, ensuring correct operation and reliability of the turnstile. It is recom-

mended to use the frame for outdoor application of the turnstiles.

1.2 Operation of the frame is allowed at ambient air temperature from – 40 to

+ 40°Сand relative air humidity of up to 98 % at 25°С.

1.3 The frame in the original package should be transported in closed freight con-

tainers or other closed type cargo transport units.

1.4 During storage and transportation the boxes can be stacked no more than 2

layers high.

1.5 Storage of the frame is allowed in dry indoor facilities at ambient air tempera-

ture from – 40 to + 45°Сand relative air humidity of up to 98 % at 25°С. The environ-

ment should be free of acid and alkali vapours and gases that cause corrosion.

1.6 After transportation or storage at temperatures below zero or at high air hu-

midity, prior to the installation the frame must be kept in the original package for 24

hours at least, under normal operation conditions (Ref. Clause 1.2).

2. TECHNICAL SPECIFICATIONS

Overall dimensions (L x W x H)..............................................................1792х1550х70 mm

Net weight:…................................................................................................................23 kg

3. STANDARD DELIVERY SET

–shell 1.....................................................................................................................1

–shell 2.....................................................................................................................1

–plate 1.....................................................................................................................1

–plate 2.....................................................................................................................2

–plate 3.....................................................................................................................1

–plate 4.....................................................................................................................1

Installation tools:

–bolt М8х20........................................................................................................... 12

–bolt М10х16......................................................................................................... 12

–bolt М10х50....................................................................................................... 12

–screw М16х60 .....................................................................................................1

–adjustment pin М8х120 ..........................................................................................8

–washer 8 (extended)............................................................................................ 12

–washer 10 (extended).......................................................................................... 12

–washer 10.......................................................................................................... 12

–washer 16 ............................................................................................................1

Technical documentation:

–certificate................................................................................................................1

–Package..................................................................................................................1

Used to fix a barrier section and a guide barrier section of the turnstile to the frame.

Used to fix a bottom bearing rotation unit of the turnstile to the frame.