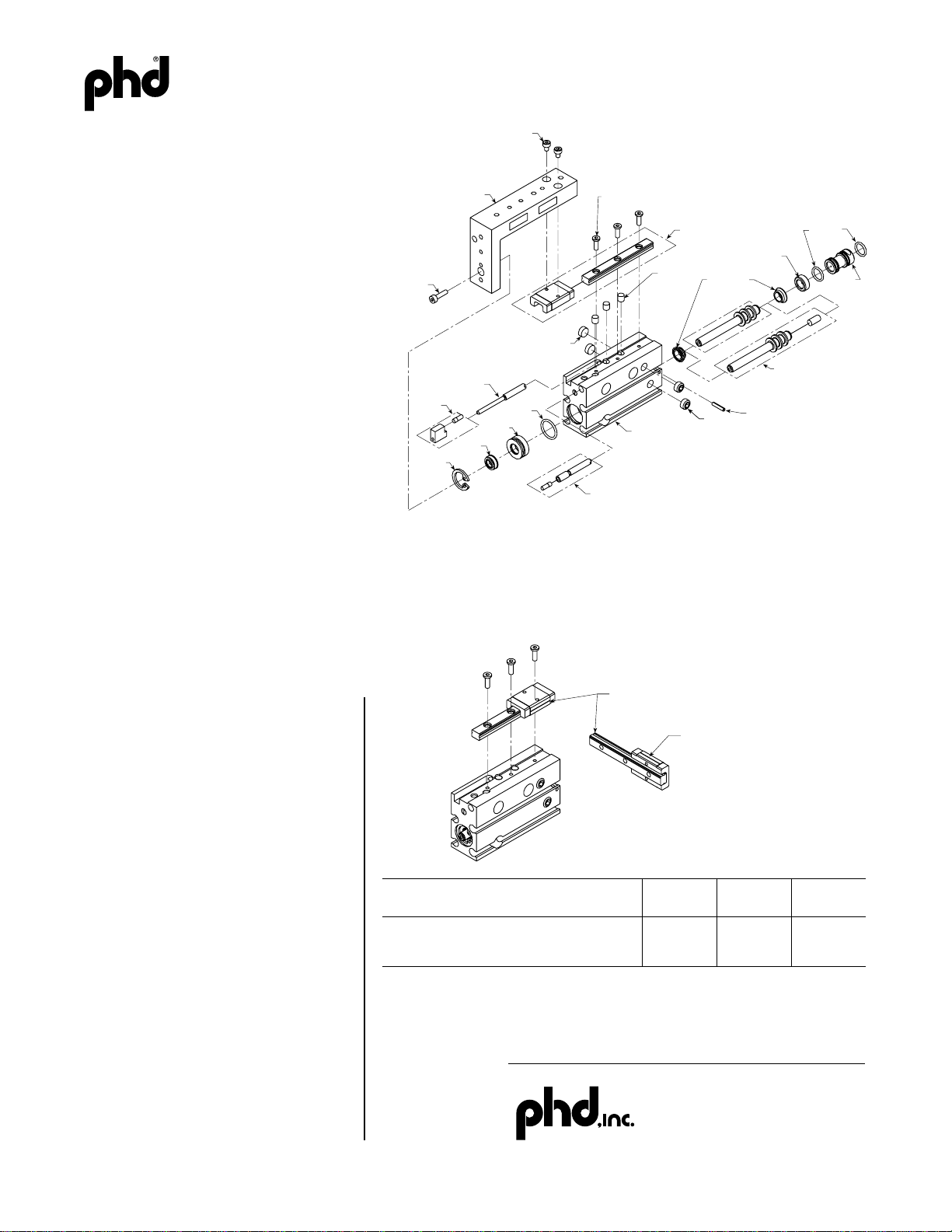

PISTON SEALS

WEAR RING

PISTON SEALS

(OPTIONAL MAGNET -M)

SIZE 08 UNITS SIZE 12 & 16 UNITS

SIZE 08 UNITS SIZE 12 UNITS

.144 [3.6]

.154 [3.9]

FIGURE 3: PIN INSERTION, in [mm]

RAIL MOUNTING SCREW

(QTY VARIES WITH TRAVEL)

RAIL & CARRIAGE

ASSEMBLY PLUG SEAL

BORE

PLUG

PISTON SEAL

PISTON & ROD

ASSEMBLY

SPRING PIN

(08 & 12 SIZES ONLY)

PORT

PLUG

BODY ASSEMBLY

PORT PLUG

EXTEND TRAVEL

ADJUSTMENT SCREW

STOP

ASSEMBLY

CARTRIDGE

CARTRIDGE

SEAL

ROD SEAL

CARTRIDGE

RETAINER

RETRACT TRAVEL

ADJUSTMENT ASSEMBLY

TOOL PLATE TO

CARRIAGE SCREW

(2 OR 4)

TOOL PLATE

TOOL PLATE TO

ROD SCREW

PORT

PLUG

WEAR RING

TRAVEL

ADJUST

PLUG

6441-417C

SERIES SHP SEAL REPLACEMENT PROCEDURES

DISASSEMBLY

1) Remove the tool plate to carriage and the tool plate to rod

screws. Lift the tool plate from the rail and carriage assembly.

2) Remove the top two side fittings or port plugs on the 12 mm

and 16 mm bore units, or the bottom two side fittings or port

plugs on the 08 mm bore unit.

3) Remove the cartridge retainer, using the appropriate tool.

4a) On the 8 and 12 mm bore units, press out the spring pin. Pull

the piston and rod assembly, as well as the cartridge assembly,

out of the front of the unit. From the rear of the body,

apply pressure to the bore plug until the rear

plug seal just becomes visible in the top-most

side ports. To prevent seal damage, insert a

5/32" [4 mm] diameter dowel into each of these

ports, and apply inward pressure to the dowels with your

fingers as you apply pressure to the rear of the bore

plug. The plug should easily press past the side

ports. Remove the dowel pins, and using a suitable

tool (a wooden dowel works well), press the bore

plug out of the front of the unit.

4b) On the 16 mm units, remove the bore plug and

cartridge retainers using the appropriate tool. Pull

the piston and rod assembly (along with the

cartridge) out of the front of the unit. Push the bore

plug out of the rear of the unit using a wooden or

plastic rod. Exercise caution not to scratch the sealing

surfaces inside the bore of the unit.

5) Discard old bore plug seals, cartridge seals, piston

seals, and rod seal. On 8 mm units, remove the wear

ring (see FIGURE 2). A pocketknife or small flat blade

screwdriver may be used to slowly force the wear ring

off of the piston and rod assembly. The wear ring may also be pressed or cut

off. Regardless of removal technique, be very careful not to damage the piston

and rod assembly.

6) Clean and inspect all components. Worn or damaged bearing components

should be replaced.

REASSEMBLY

1) In general, use a petroleum-based lubricant (grease) for the

lubrication of the slide during assembly.

2) Re-lubricate and assemble the rod seal into the cartridge, with

the shaft wiper side of the seal facing towards the tool plate end of

the cartridge. Install the cartridge seal onto the cartridge and lightly

lubricate. Install bore plug seals and lightly lube.

3a) On 8 and 12 mm units, insert the bore plug into the front of the

unit, and gently push in using a suitable rod. Push the plug into the body until the

rear plug seal just becomes visible in the top-most side ports. To prevent seal

damage, insert a 5/32" [4 mm] diameter dowel into each of the top side ports, and

apply constant inward pressure to the pins with your fingers. Holding the pressure

on the pins, push the bore plug into position. Align the spring pin groove with the

holes in the body. A fitting or suitable screw may be installed in the bore plug port

and used to rotate the plug to align the spring pin groove with the spring pin hole in

the body. Install the spring pin to the proper depth per FIGURE 3.

3b) On 16 mm units, insert the plug from the rear of body, making sure the side

communication hole is lined up with a side port. Install the plug retainer using the

proper tool.

4) Lightly lubricate and install the piston seals. See FIGURE 2 for the proper seal

orientation. On 8 mm units, install the wear ring (see FIGURE 2). The wear ring is

pressed onto the end of the piston and rod assembly. The chamfered side of the

wear ring is installed toward the piston seals. When pressing on the wear ring, support the piston and rod assembly so that the installation force does not bend the

piston rod. Also be careful not to scratch or damage the piston and rod assembly.

5) Install the rod seal cartridge onto the rod, making sure the end of the rod passes

through the rod seal before applying force. NOTE: There are two versions of rod

seal cartridges. To identify which end of the cartridge to insert into the body,

look inside the cartridge. The end with the smaller diameter opening should

be inserted into the body.

(continued on reverse side)

For additional technical assistance, call:

P.O. Box 9070, Fort Wayne, IN 46899

1-800-624-8511

FIGURE 2

FIGURE 1