PART NO.: 6441-814

4

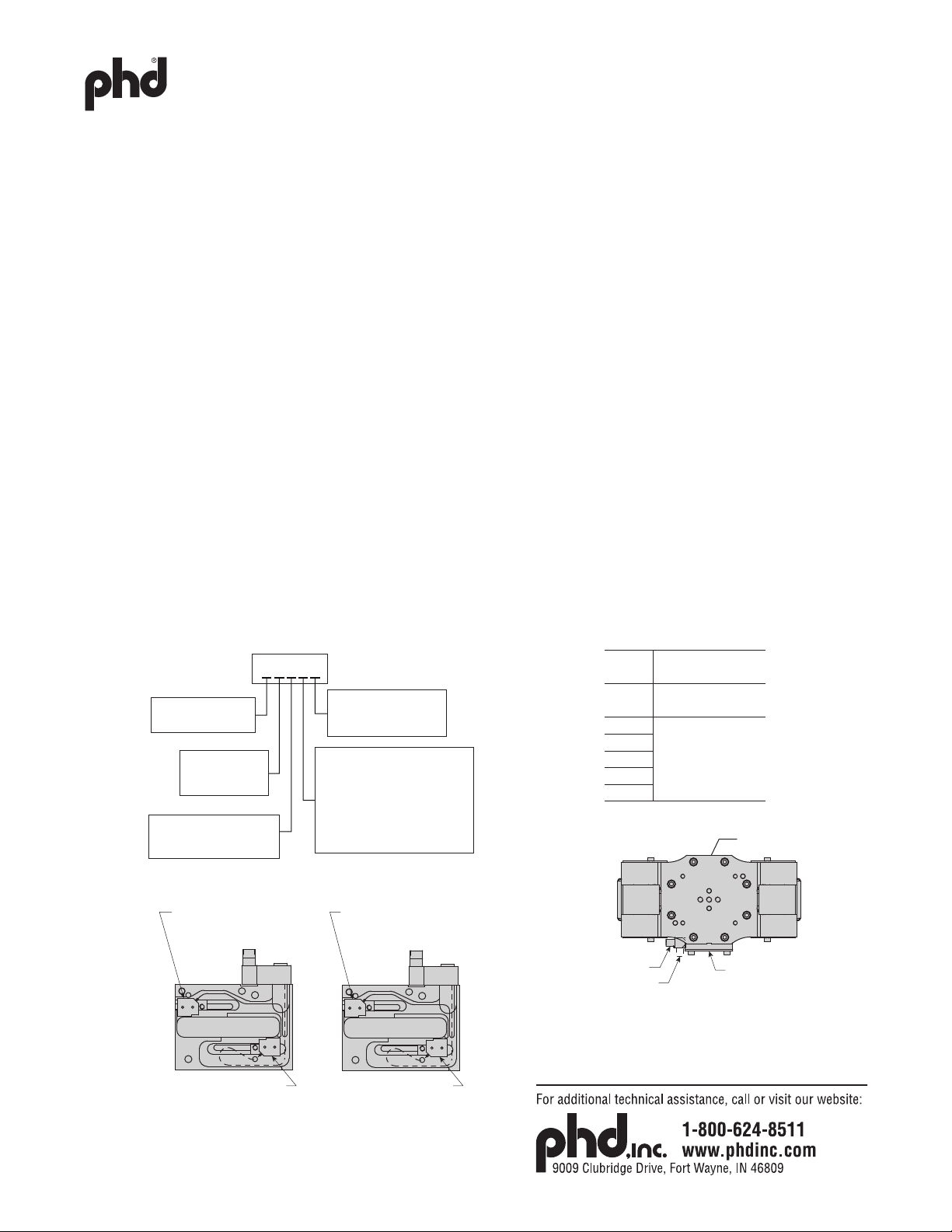

COMPLETE ASSEMBLY (CONTINUED):

4) Insert dowel pin (10) into cam (6) as shown.

5) Assemble links (9) onto dowel pins (10) as shown.

6) Twist cam (6) and insert protrusions into slider slots in body (1).

7) Using Magna-Lube G or equivalent lubricant, lubricate the following:

a. Piston (3) in seal groove and around outside diameters.

b. Piston seal (24) completely.

8) Insert piston seal (24) into seal groove of piston (3) making sure seal is not twisted.

9) Insert piston and rod sub-assembly (2, 3, 23, 24) into body passing piston rod (2) through piston rod seal (25) until piston seal is in

bore of body (1). Continue to insert piston and rod assembly to bottom of bore with links (9) oriented as shown.

10) Insert fastener (22A) through cam (6) and into piston rod (2). Hold fastener (23) rigid with hex wrench, tighten fastener (22A)

to 700 in-lb [79.09 Nm]. Wipe away any excess adhesive from piston (3) and fastener (23).

11) Insert dowel pins (16) into holes of body (1).

12) Using Magna-Lube G or equivalent lubricant, lubricate the following:

a. Seal groove and manifold seal surface of bore plug (4).

b. O-ring seal (26) completely.

c. Manifold seal (27) completely.

13) Insert o-ring seal (26) into groove of bore plug (4) and insert this assembly onto body (1) noting orientation of dowel pins (16) and

port of bore plug (4). An arbor press is recommended only to keep body (1) and bore plug assembly (4, 26) oriented parallel to each

other. Press until bore plug assembly (4, 26) is seated in body (1).

14) Insert manifold seal (27) in manifold seal cavity of bore plug (4).

15) Place bushing block (5) onto body (1) aligning port and dowel pin holes with dowels (16).

16) Insert bushing block fasteners (19) through bushing block and thread into body (1). Tighten to 300 in-lb [33.9 Nm].

17) Using Nye Rheolube or equivalent lubricant, lubricate the following:

a. Bushing block (5) pivot pin holes and surfaces that will mate with jaws

b. Jaw (7A) pivot pin holes

c. Pivot dowel pins (17) completely

d. Clevis (7B) bearing pin holes and surfaces that will mate with links (roller bearing pin holes on jaw (7A) for “W” style jaw)

e. Roller bearing (8) completely

18) Aligning pivot pin hole on bushing block (5) with pivot pin hole of jaw (7A) of finished jaw sub-assembly, insert pivot dowel pins (17)

through both bushing block (5) and jaw (7A).

19) Align slot of link (9) with bushing pin hole of clevis (7B). Insert roller bearing dowel pin (18) just enough to hold link in place.

20) Align hole of roller bearing (8) to roller bearing dowel pin (18) and push pin in enough to hold roller bearing in place.

21) Align slot of second link (9) to roller bearing dowel pin (18) ensuring that links (9) and roller bearing (8) are all inside legs of clevis

(7B) and push roller bearing dowel pin (18) until end is flush with edge of clevis (7B).

22) Insert washer (11) and fastener (12) on each side of clevis (7B). Tighten fastener to 85 in-lb [9.6 Nm]. Do this step on each

jaw assembly.

23) Using Nye Rheolube or equivalent lubricant, apply lube to grease zerk (7D) of jaw (7A). Continue to apply lube until it is visible around

pivot dowel pins (17). Wipe away any excess lube.

24) Pivot pin retaining:

a. Standard clamp: Insert washer (20) and fastener (21) on each side of bushing block (5). Tighten fastener to 125 in-lb [14.1 Nm].

Do this for both pivot pins (17).

b. WC1 option: Place optional weld cover over jaw (7A) and bushing block (5) aligning holes/slots with threads in bushing

block (5) and body (1). Insert fasteners (21) through weld cover into threads of bushing block (5) and body (1). Tighten

fasteners to 125 in-lb [14.1 Nm].

25) For units with WC1 option, insert weld cover gasket (38) and weld cover plate (37) into bushing block (5) aligning holes with threads

in bushing block (5). Insert fasteners (21) and tighten to 50 in-lb [5.65 Nm].

26) Front cover/switch assembly (see Figure 2, page 2):

a. Standard clamp: Insert cover plate (13) and fasteners (21). Tighten fasteners to 125 in-lb [14.1 Nm]. Do this on both sides of clamp.

b. For positional sensing option:

i. Insert target driver (30) into thread of cam (6) on side of clamp where switch is to be. Tighten to 200 in-lb [22.6 Nm].

ii. Using Nye Rheolube or equivalent lubricant, lubricate the following:

1. Target driver (30) outside diameter

2. Target (29) completely

3. Switch housing (28) target slot

TEARDOWN AND REBUILD PROCEDURES: SERIES PFC FRAME CLAMPS