THE PHD WARRANTY COVERS THE CYLINDER, ISO VALVE,

MANIFOLD AND ALL OTHER COMPONENTS ON THE CYLINDER

WITH THE EXCEPTION OF THE -X26 CHECK VALVE. THE CHECK

VALVE IS PROVIDED AS A SERVICE TO THE CUSTOMER, BUT

DOES NOT CARRY THE PHD WARRANTY.

®SERIES BCS2-6 STRETCHING CYLINDER

REBUILD PROCEDURES

These procedures include instruction for units with cushions.

P.O. Box 9070, Fort Wayne, IN 46899

1-800-624-8511

For additional technical assistance, call:

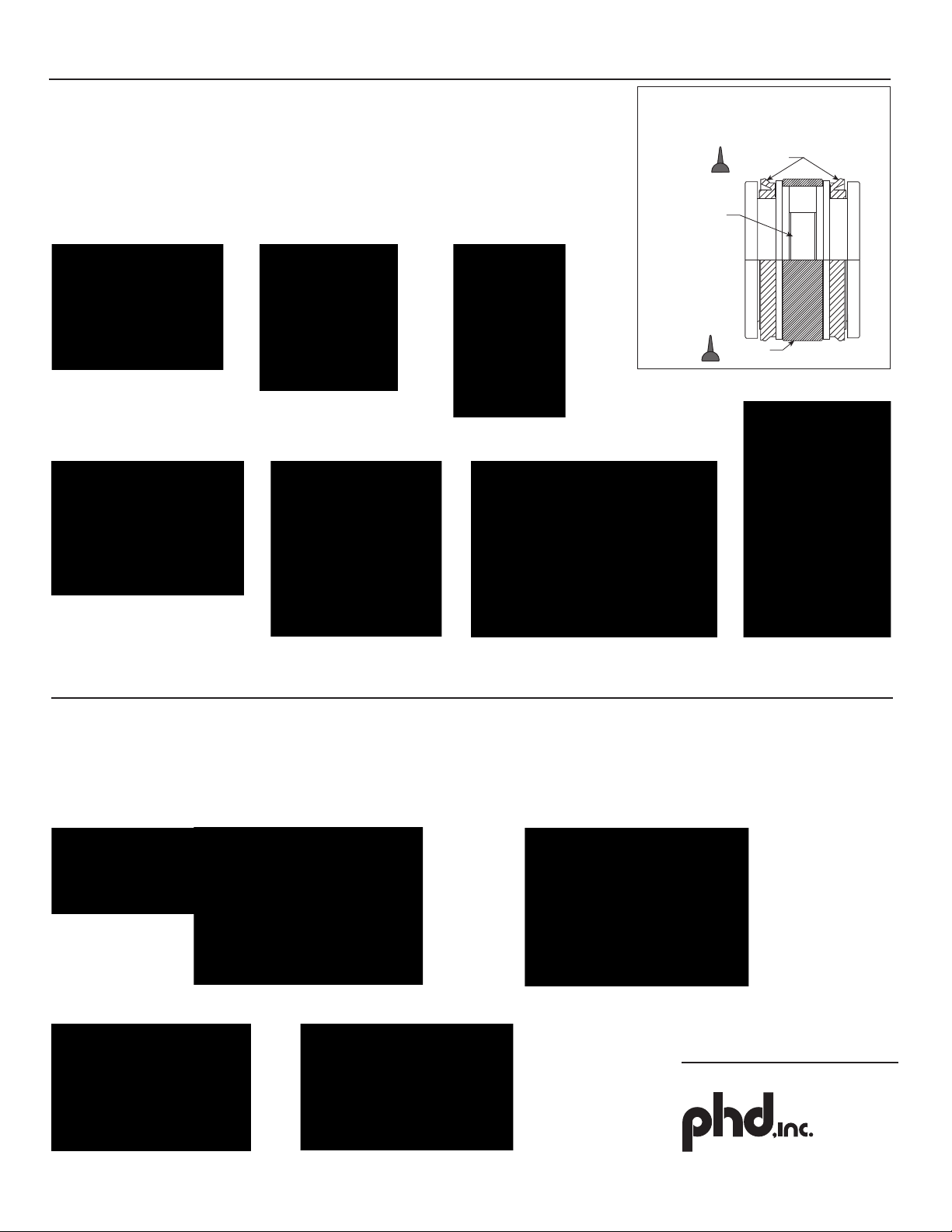

FIGURE 1

SHCS

MANIFOLD BLOCK

ASSEMBLY

MUFFLER

MUFFLER

STEEL TUBING

O-RING SEAL

MANIFOLD BLOCK

MANIFOLD TO

HEAD O-RING

SEAL

CAP ASSEMBLY

SHOULDER BOLT

W/ FEMALE THREAD

CAP

RETAINING RING

CUSHION NEEDLE

ASSEMBLY

MULTI-FUNCTION

IMPACT SEAL

CUSHION

O-RING SEAL

PISTON

SEAL

STEEL TUBING

O-RING SEAL

WEAR RING

PISTON SEAL

PISTON

PISTON & ROD

ASSEMBLY

STEEL TUBE

ROD CYLINDER

TUBE BORE

MULTI-FUNCTION

IMPACT SEAL

HEAD

ASSEMBLY

HEAD ROD BEARING

ROD SEAL

SHOULDER BOLT

W/ FEMALE THREAD

FLANGE

RETAINING

RING

FLANGE TO MANIFOLD

CAP SCREWS

JAM NUT

ROD EYE

FLANGE TO HEAD

CAP SCREWS

REBUILD/REASSEMBLY

1) Be careful to prevent cutting or damaging seals

during reassembly.

2) Use FDA Regulation 21CFR 178.3570 lubricant for

lubrication of air cylinders during reassembly.

3) Use FIGURE 1 for reference.

HEAD ASSEMBLY

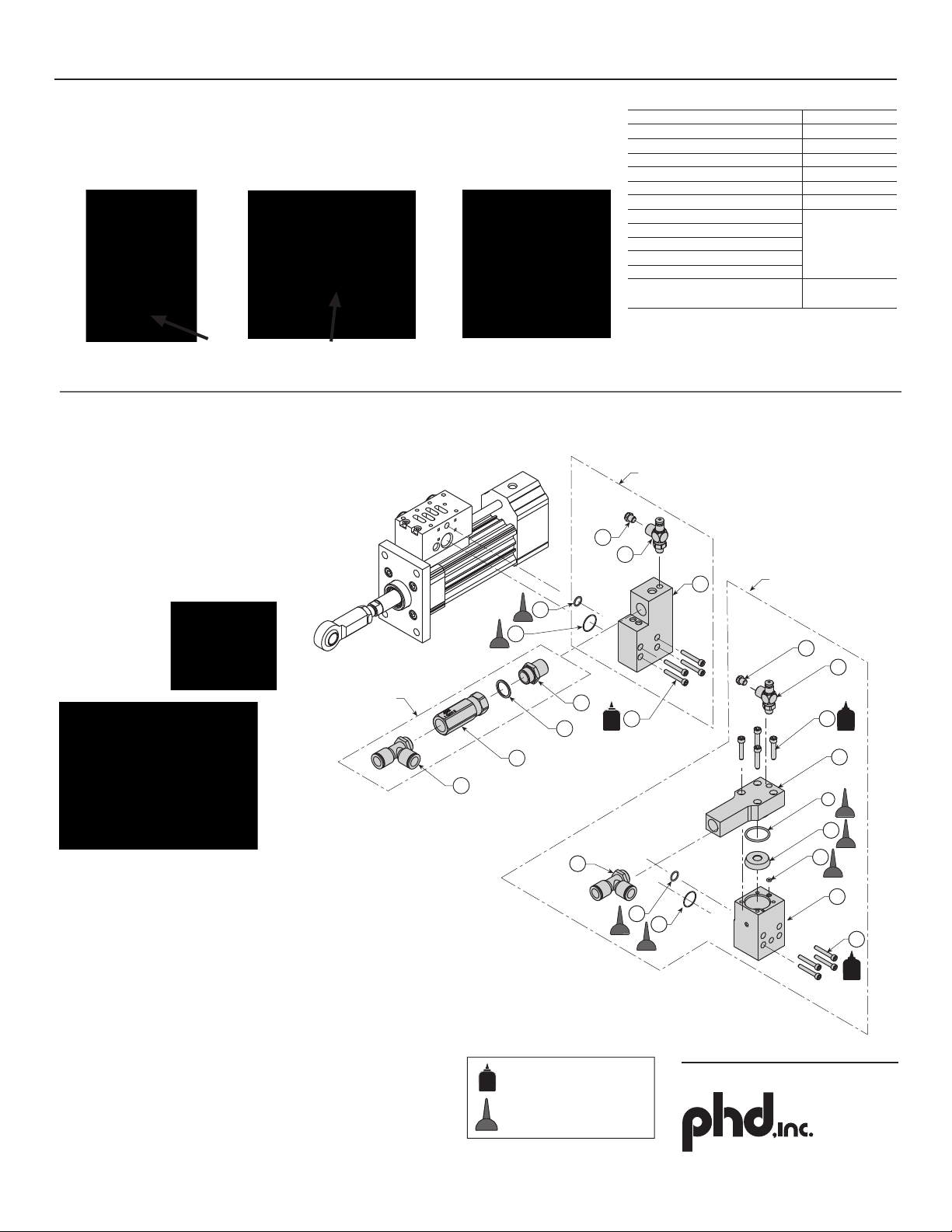

A1) Press rod bearing into head, from end with snout, until flush as shown.

See FIGURE 2.

A2) Lubricate rod seal cavity and press in rod seal. Install retaining ring.

A3) Install multi-function impact seal in head.

!

Pre-lubricate rod seal cavity.

Pre-lubricate rod seal.

Insert rod seal into cavity.

Press rod bearing into head, from

end with snout, until flush as shown.

Lightly lubricate and install

multi-function impact

seal to head.

Caution: Over lubrication may cause cushion to malfunction.

TOOLS NEEDED:

Hex wrenches: M2.5, M4, M5, M6, and M8

Pliers

Small flat blade screwdriver

M24 open end or adjustable wrench

22 mm diameter pin or socket

(to press in rod bearing and rod seal)

Arbor press

20-250 in-lb torque wrench with

M2.5, M4, M5, M6 and M8 hex attachments

Press in rod seal.

PART NO.: 6441-503L

1

= LOCTITE 242 THREAD LOCKER

= LUBRICANT PER FDA

REGULATION 21CFR 178.3570

A1 A2

After installing retaining ring, apply a small amount of

lubrication to inside of rod seal.

A3

DISASSEMBLY OF THE CYLINDER

1) WARNING: All air pressure in the unit must be

exhausted prior to disassembly of nozzle cylinder.

2) Remove valve from manifold (valve not shown).

3) Remove mufflers from manifold if necessary.

4) Remove check valve, fitting adaptor, and male run tee

from manifold/inlet adaptor. If -X25, -X26 or -X27

(inlet adaptor) is present, remove from manifold.

5) Remove flange, rod eye, and jam nut.

6) Remove cap, carefully slide cap away from tube as not

to bend steel tube.

7) Remove steel tube.

8) Remove manifold.

9) Remove head.

10) Slide piston rod assembly from cylinder tube.

11) Remove all seals, noting orientation (especially note

orientation of rod seal). Exercise caution to prevent

scratching of the sealing surfaces. See FIGURE 2.

12) Remove cushion needle assembly (these items are

sold in separate kits from the cylinder repair kit).

13) Clean and inspect all components. Excessively worn or

damaged components should be replaced.

14) Clean flange bearing bore shoulder with acetone to

remove adhesive.

FIGURE 2

ROD BEARING

RETAINING RING

ROD SEAL,

NOTE ORIENTATION

FLANGE HEAD

FLANGE BEARING

BORE SHOULDER

FILL GROOVE

IN THIS

LOCATION