MP162EK 1.1.0 09/2019. 0.3

Safety Informaon

Intended Use

The linear actuator is a laboratory device as

dened by DIN EN 610101. It is intended for

indoor use and use in an environment that is

free of dirt, oil, and lubricants.

In accordance with its design, the linear actu-

ator is intended for singleaxis posioning and

adjusng of loads at various velocies and with

dened forces. The linear actuator is intended

for applicaons in automaon or handling

technology.

The linear actuator is not intended for applica-

ons in areas where failure would be a consi-

derable risk for people or the environment. For

further informaon on the ambient condions,

see „Ambient Condions and Classicaons“ in

the manual.

The intended use of the linear actuator is

only possible when completely installed and

connected, and in conjuncon with a suitable

controller. The linear actuator may only be

installed, operated, maintained, and cleaned

by authorized and appropriately qualied

personnel.

Installaon

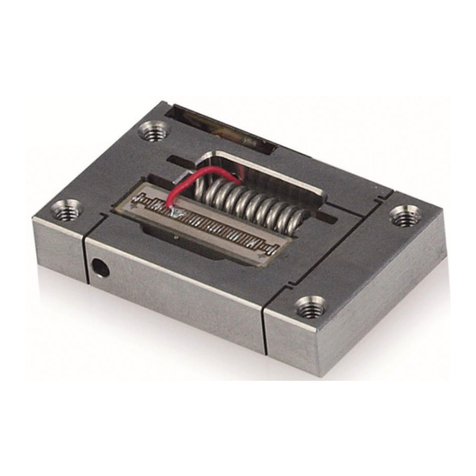

The linear actuator contains permanent

magnets. Their magnec elds can disturb or

damage sensive devices and objects (e.g.,

heart pacemakers, EC cards, magnec storage

devices). Loose magnezable objects (e.g., iron,

steel) could be aracted and cause material

damage. The magnec elds are also eecve

when the linear actuator is not connected or

switched o.

XMake sure that people with heart pace

makers and / or electronic implants do not

have access to the linear actuator.

XRemove loose magnezable objects and

sensive objects from the area where the

linear actuator is to be installed.

XMake sure that the danger zone is marked

and the necessary precauons have been

taken.

The linear actuators can generate high forces

at high velocies. Risk of minor injuries from

cung or crushing between the runner or the

contact part of the linear actuator and a xed

part or obstacle.

XUse safeguards to protect limbs in areas

where they could be caught by moving

parts.

XMaintain safety distances according to DIN

EN ISO 13857.

XIf possible, use contact parts with a su-

ciently dimensioned contact surface. The

pressure on the contact surface at maxi-

mum force of the linear actuator should not

exceed 50 N/cm².

Mechanical forces can damage or misalign the

linear actuator.

XKeep the linear actuator only in its housing.

XAvoid shocks and drops.

XDo not exceed the maximum permissible

forces and torques (see manual).

XAvoid lateral forces on the runner.

XTransport the linear actuator only in the

original packaging and with the safeguard

aached.

Incorrectly ed screws and locang pins can

cause damage.

XPay aenon to the maximum ghtening

torque (see manual).

XDo not allow screw heads to protrude.

XSelect the screw length according to the

depth of the mounng holes.

Unsuitable mounng could warp the linear

actuator and reduce the accuracy.

XMount the linear actuator on a level surface

with similar thermal expansion properes

(see manual for recommended atness).

Dirt, oil, lubricant, and condensaon make the

drive of the linear actuator inoperable.

XKeep the linear actuator free of dirt, lubri-

cants, and condensaon.

Collisions can damage the linear actuator, the

load to be moved, and the surroundings.

XMake sure that the runner cannot collide

with the load or the surroundings within

the moon range of the linear actuator.

XDo not place any objects in areas where

they can be caught by moving parts.

MOTION | POSITIONING