User Guide

Doc# A824D001 v2.0

15-Nov-2018

Page 3 of 28

PI (Physik Instrumente) L.P.

16 Albert Street, Auburn, MA 01501

Tel: 508-832-3456 Fax: 508-832-0506

Email: air@pi-usa.us

Table of Contents

1. About this Document..................................................................................................................................................5

1.1. Objective and Target Audience of this User Guide .....................................................................................................5

1.2. Symbols and Typographic Conventions ......................................................................................................................5

1.3. Other Applicable Documents ......................................................................................................................................5

2. Safety..........................................................................................................................................................................6

2.1. Intended Use ...............................................................................................................................................................6

2.2. General Safety Instructions.........................................................................................................................................6

2.3. Organizational Measures............................................................................................................................................6

2.4. Personnel Qualification...............................................................................................................................................6

2.5. Warnings and Safety Notices......................................................................................................................................7

3. Unpacking...................................................................................................................................................................7

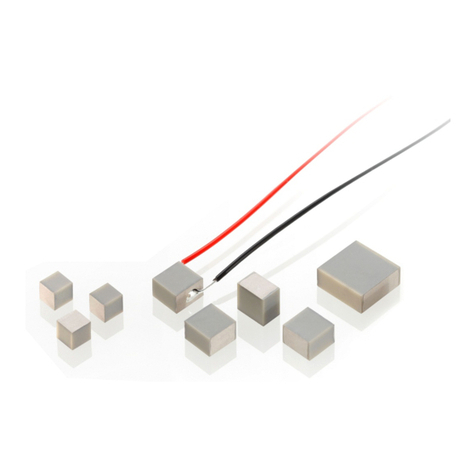

4. Product Overview .......................................................................................................................................................8

4.1. Model Overview and Part Numbering ........................................................................................................................8

4.2. Product Description.....................................................................................................................................................8

4.3. Product Features.........................................................................................................................................................8

4.4. Product Views .............................................................................................................................................................9

4.5. Product Labeling .......................................................................................................................................................10

4.6. Scope of Delivery.......................................................................................................................................................11

4.7. Upgrade Options.......................................................................................................................................................11

5. Mounting..................................................................................................................................................................12

6. Connecting the Cables ..............................................................................................................................................12

7. Hardware Interlock ...................................................................................................................................................12

8. Connecting the Controller to Protective Earth ..........................................................................................................13

9. User I/O ....................................................................................................................................................................14

9.1. Analog Inputs............................................................................................................................................................14

9.2. Analog Outputs .........................................................................................................................................................14

9.3. Digital I/O .................................................................................................................................................................15

10. Axis Numbering.....................................................................................................................................................17

11. Software Installation on Host PC...........................................................................................................................18

12. Establishing Host PC Communications with the Controller....................................................................................18

13. Operation..............................................................................................................................................................19